Bucket tooth mounting structure and mounting pin assemble

A technology for mounting structures and mounting pins, which can be used in earth movers/excavators, construction, etc., and can solve problems such as complex manufacturing of adapters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

[0061]

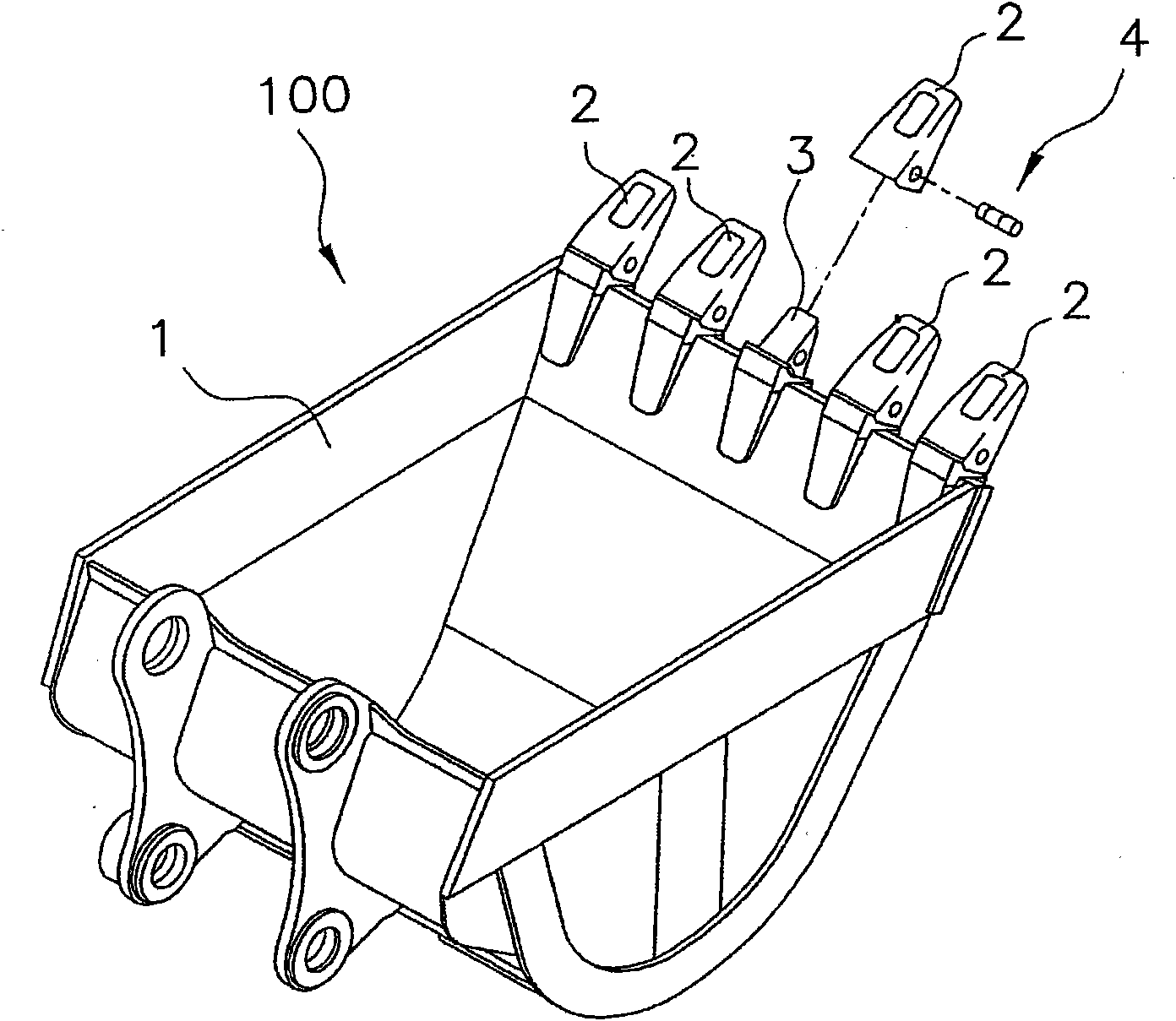

[0062] figure 1 with figure 2 The tooth attachment structure of the bucket according to the first embodiment of the present invention is shown. Such as figure 1 As shown, the bucket tooth installation structure is a structure for detachably installing bucket teeth 2 on the body part 1 of the bucket 100 , and has bucket teeth 2 , adapters 3 and mounting pin assemblies 4 .

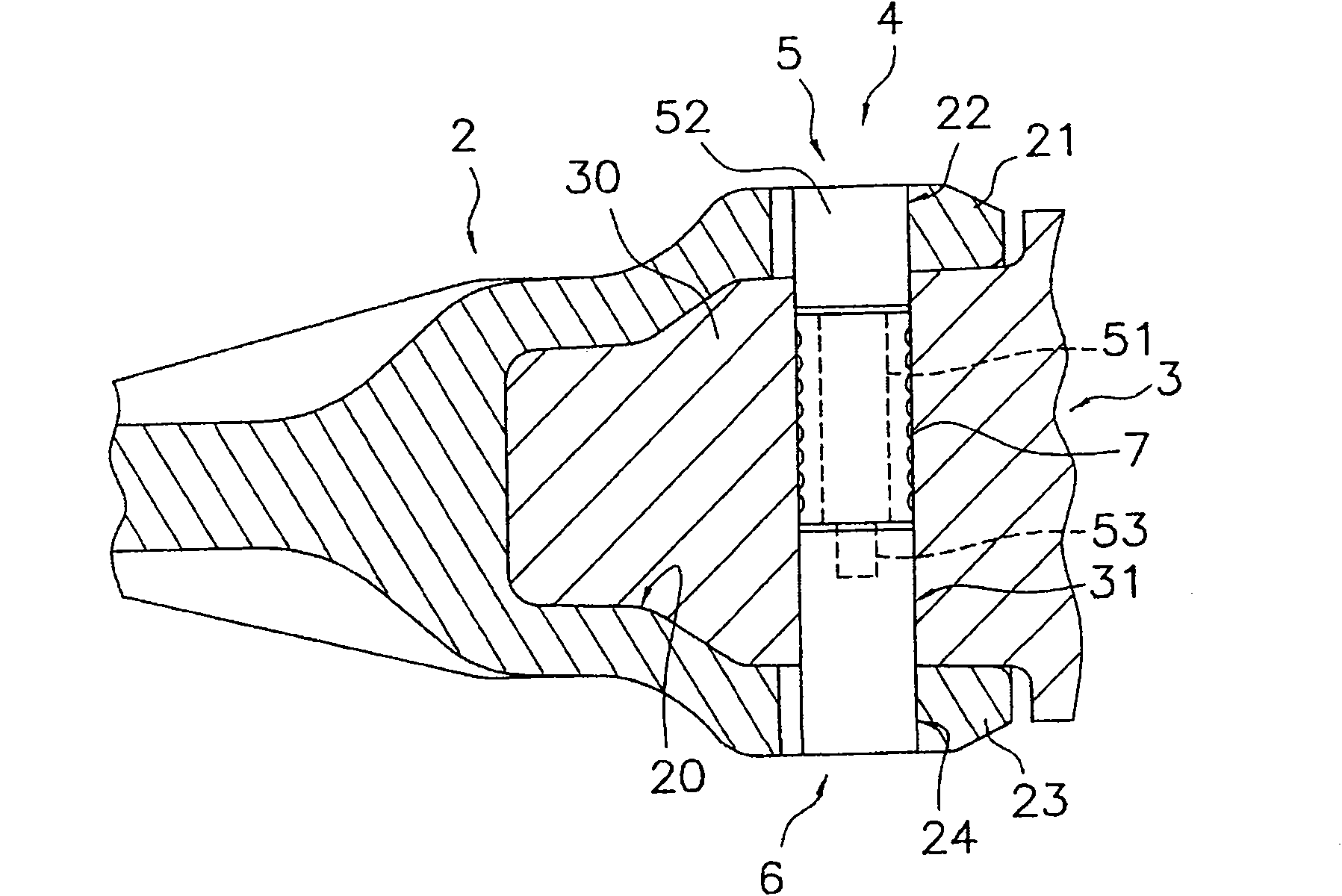

[0063] Such as figure 1 As shown, the bucket tooth 2 has a wedge-shaped shape with a tapered front end, such as figure 2 As shown, the bucket tooth 2 is formed with a concave portion 20 that is depressed from the rear end toward the front end. On one side wall 21 of the concave portion 20 (hereinafter referred to as “first side wall 21”), a hole 22 penetrating from the outside of the bucket tooth 2 to the inside of the concave portion 20 is provided, and on the other side wall 23 of the concave portion 20 (hereinafter referred to as Corresponding to the hole of the first side wall 21 , a...

no. 2 approach 〕

[0087]

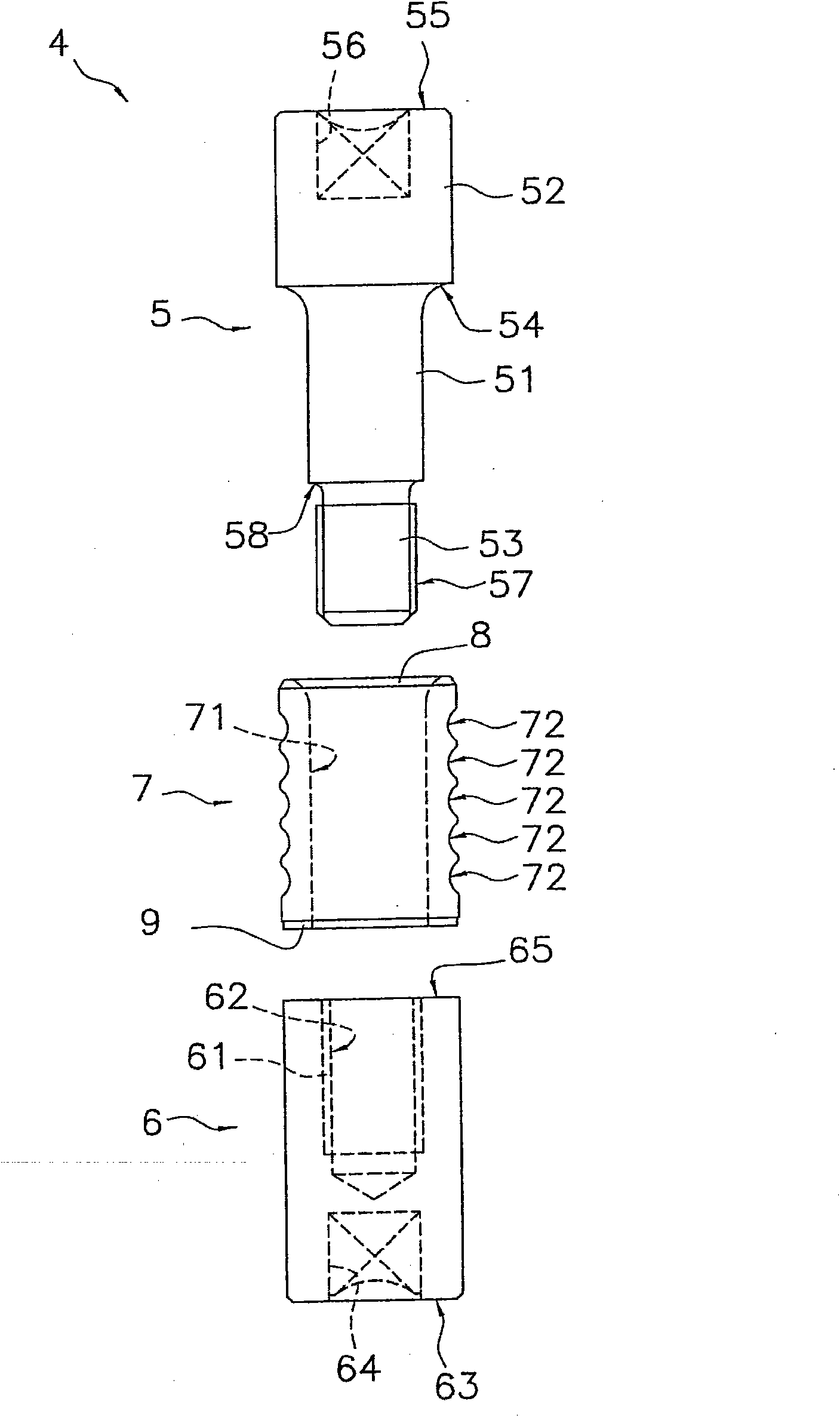

[0088] Image 6 The tooth attachment structure of the bucket according to the second embodiment of the present invention is shown. In this tooth mounting structure, annular grooves 41 to 43 extending in the circumferential direction are respectively formed on the outer peripheral surfaces of the first mounting pin 5 and the second mounting pin 6 of the mounting pin assembly 4 . exist Image 6 In the description, the same reference numerals are assigned to the parts corresponding to the respective parts of the tooth attachment structure of the bucket according to the first embodiment.

[0089] If it demonstrates in more detail, it will be as follows. A groove 41 (hereinafter referred to as “first groove portion 41 ”) is provided in the large-diameter portion 52 in the first mounting pin 5 . In a state where the mounting pin assembly 4 is inserted into the hole 31 of the adapter 3 , the first groove portion 41 is disposed inside the hole 31 of the adapter 3 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com