Oil-based solid cosmetic preparation

A cosmetic and oil-based technology, which is applied in the field of oil-based solid cosmetics, can solve problems such as high melt viscosity, poor dispersion, and stains, and achieve good dispersion, excellent repairing effect, and excellent skin damage repairing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

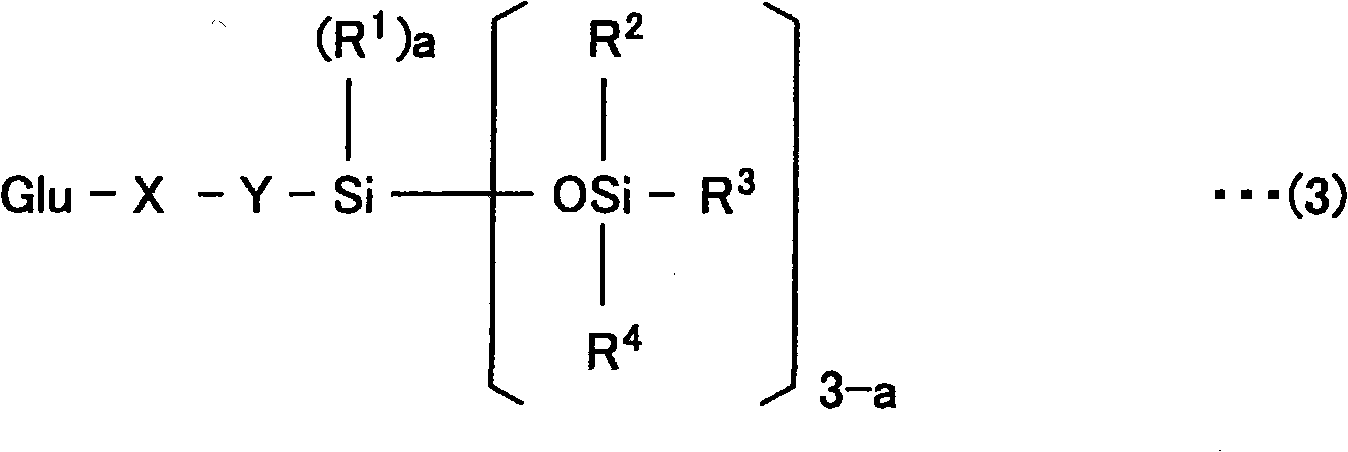

Method used

Image

Examples

Embodiment 1~7、 comparative example 1~4

[0066] (prescription)

[0067] Oily solid cosmetics were produced according to the formulations shown in Table 1 and Table 2 below, and their effects were evaluated by the evaluation method described later. In addition, the results of the evaluation are also shown in Table 1 and Table 2 together.

[0068] [Table 1]

[0069]

[0070] [Table 2]

[0071]

[0072] (Manufacturing method of oil-based solid cosmetics in Table 1 and Table 2)

[0073] Each component is heated and dissolved at a temperature of 90 to 100°C, followed by stirring and mixing, defoaming, and cooling.

[0074] [Evaluation method]

[0075] Professionals (6) use the oily solid cosmetics produced by the above-mentioned embodiments 1 to 7 and comparative examples 1 to 4, according to 5 grades, to the dispersibility of the color material (no stain degree (that is: no stain) Degree)), hiding power, color rendering degree (degree of coloring) were evaluated, and judged using the following evaluation crite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com