Direct flame type solid oxide fuel battery pack and preparation method thereof

A technology of solid oxide and fuel cell stacks, applied in the field of electrochemical power generation, can solve the problems of high cost and complicated preparation process, and achieve the effects of low production cost, uniform heat distribution and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

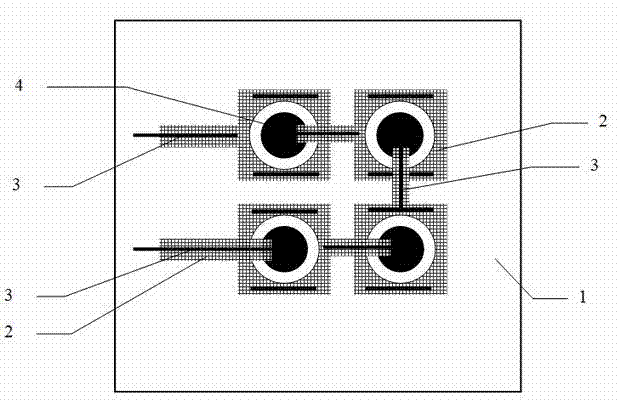

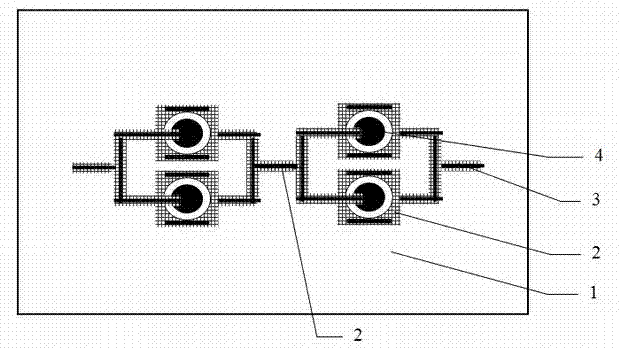

[0015] Specific implementation mode one: the following combination Figure 1 to Figure 18 Describe this embodiment, this embodiment includes a high temperature resistant insulating sheet support 1, a plurality of conductive grids 2, a plurality of wires 3 and a plurality of single cells 4,

[0016] A plurality of holes are arranged on the high-temperature-resistant insulating sheet support body 1, and each hole is covered with a conductive mesh 2, the conductive mesh 2 is fixedly connected with the high-temperature-resistant insulating sheet support body 1, and each conductive mesh 2 is glued on the upper surface A single cell 4, the bonding surface of the single cell 4 and the conductive network 2 is an anode, and a plurality of single cells 4 are connected in series, parallel or mixed through the wire 3 to form a battery pack, and the cathode and anode of the battery pack are drawn out by the wire 3 .

[0017] In this embodiment, the size of the hole on the high-temperature...

specific Embodiment approach 2

[0019] Specific implementation mode two: the following combination Figure 1 to Figure 3 This embodiment is described. The difference between this embodiment and Embodiment 1 is that a conductive mesh 2 is provided between the wire 3 and the high-temperature-resistant insulating sheet support 1 . Other components and connections are the same as those in Embodiment 1.

[0020] The conductive wire 3 is fixed on the conductive net 2 with a conductive paste adhesive, the conductive net 2 can prevent the flame from directly contacting the conductive wire 3 during combustion, and can prevent the conductive wire 3 from being fused. At the same time, the catalyst can be deposited on the conductive net 2, which is beneficial to improve the electrochemical catalytic performance and anti-carbon deposition performance of the battery pack.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that it also includes a catalyst layer, and the surface of the conductive grid 2 is covered with a catalyst layer. Other compositions and connections are the same as those in the first or second embodiment.

[0022] Attaching the catalyst on the conductive net can improve the electrochemical performance of the battery pack of the present invention. The catalyst layer can be realized by means of impregnation, coating and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com