Production system and method of single-surface single-layer blue ray disc

A Blu-ray Disc, production system technology, applied in optical recording/reproduction, optical record carrier, optical record carrier manufacturing, etc., can solve the problems of high substrate birefringence, energy consumption, high temperature and high energy consumption, etc., to achieve Overcoming high birefringence, saving energy and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

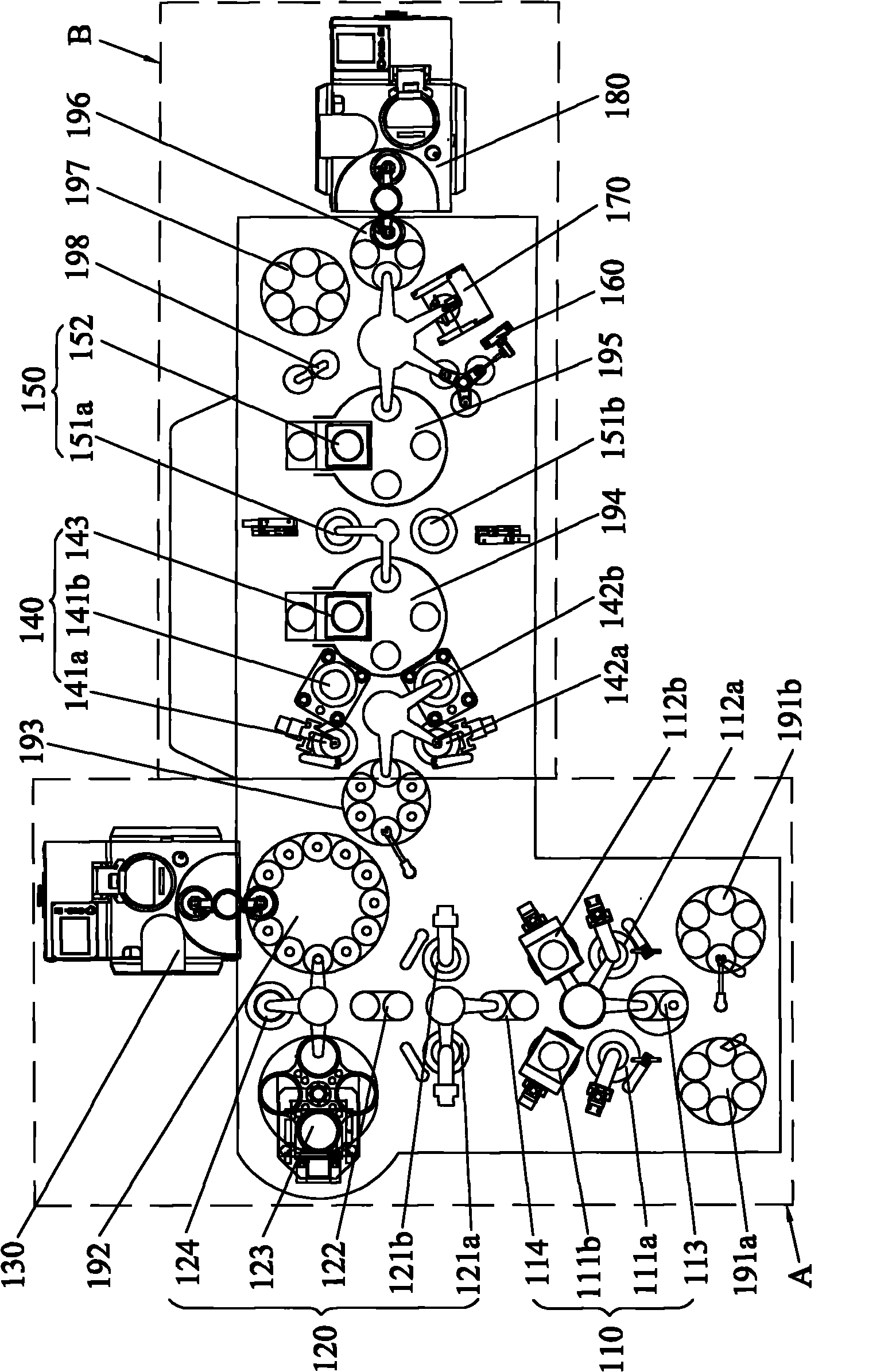

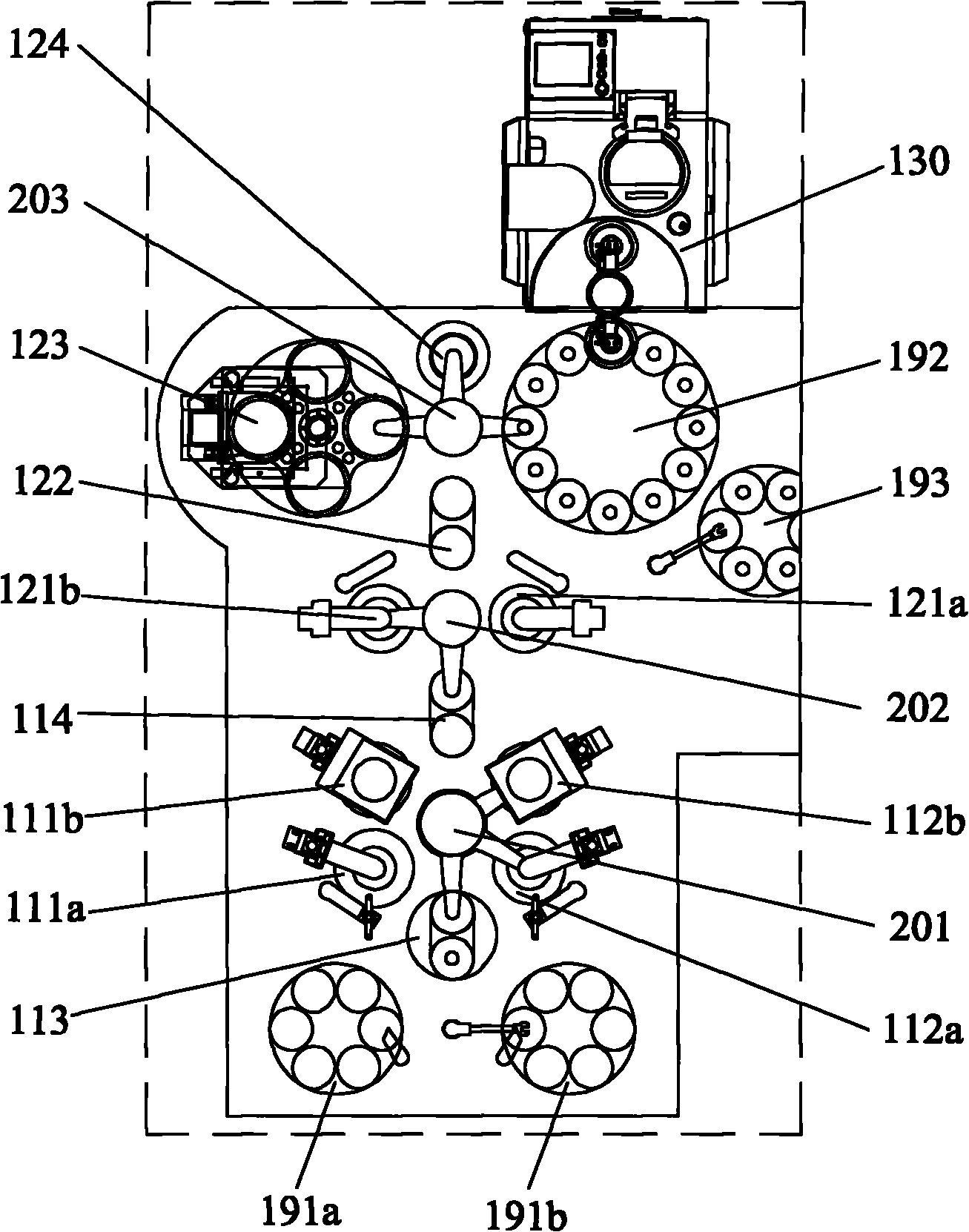

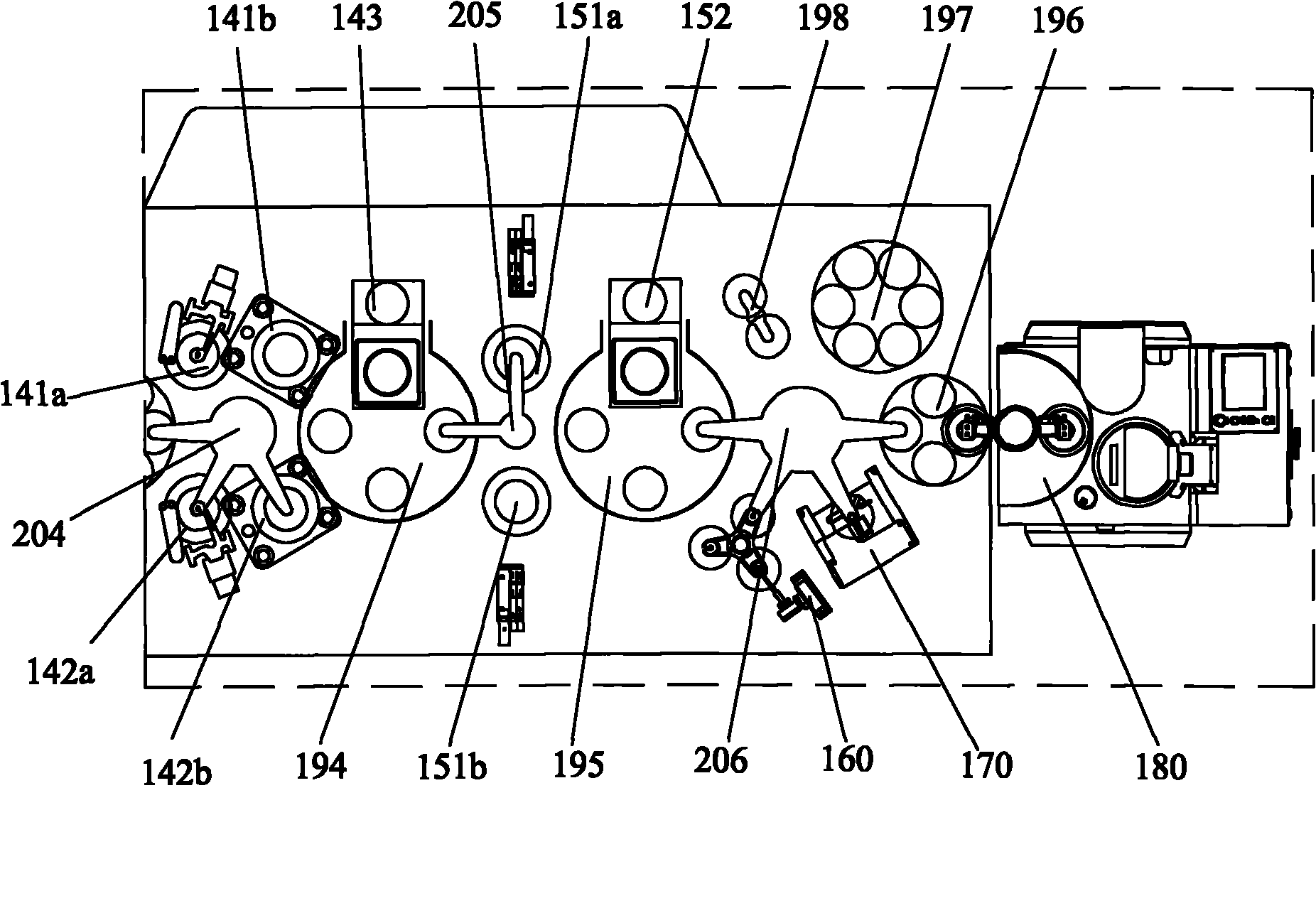

[0042] In order to describe the technical content and structural features of the present invention in detail, the following will be further described in conjunction with the embodiments and accompanying drawings, wherein the same reference numerals in different drawings represent the same components.

[0043] like figure 1 As shown, the single-sided single-layer Blu-ray disc production system of the present invention includes a first spin coating and curing mechanism 110, a recording layer forming mechanism 120, a first sputtering station 130, a second spin coating and curing mechanism 140, and a third spin coating and curing mechanism 150 , flipping mechanism 160, detection mechanism 170 and the second sputtering station 180, the first sputtering station 130 is used for sputtering reflective layer, the second sputtering station 180 is used for sputtering waterproof layer, recording layer forming mechanism 120 is used for Forming the optical disc recording layer, the first spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com