Diesel engine valve lubricating device

A lubricating device and diesel engine technology, applied in the lubrication of valve accessories, controlling the pressure of lubricants, etc., can solve the problems of friction movement wear, abrasion, and the inability to form a lubricating oil film well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

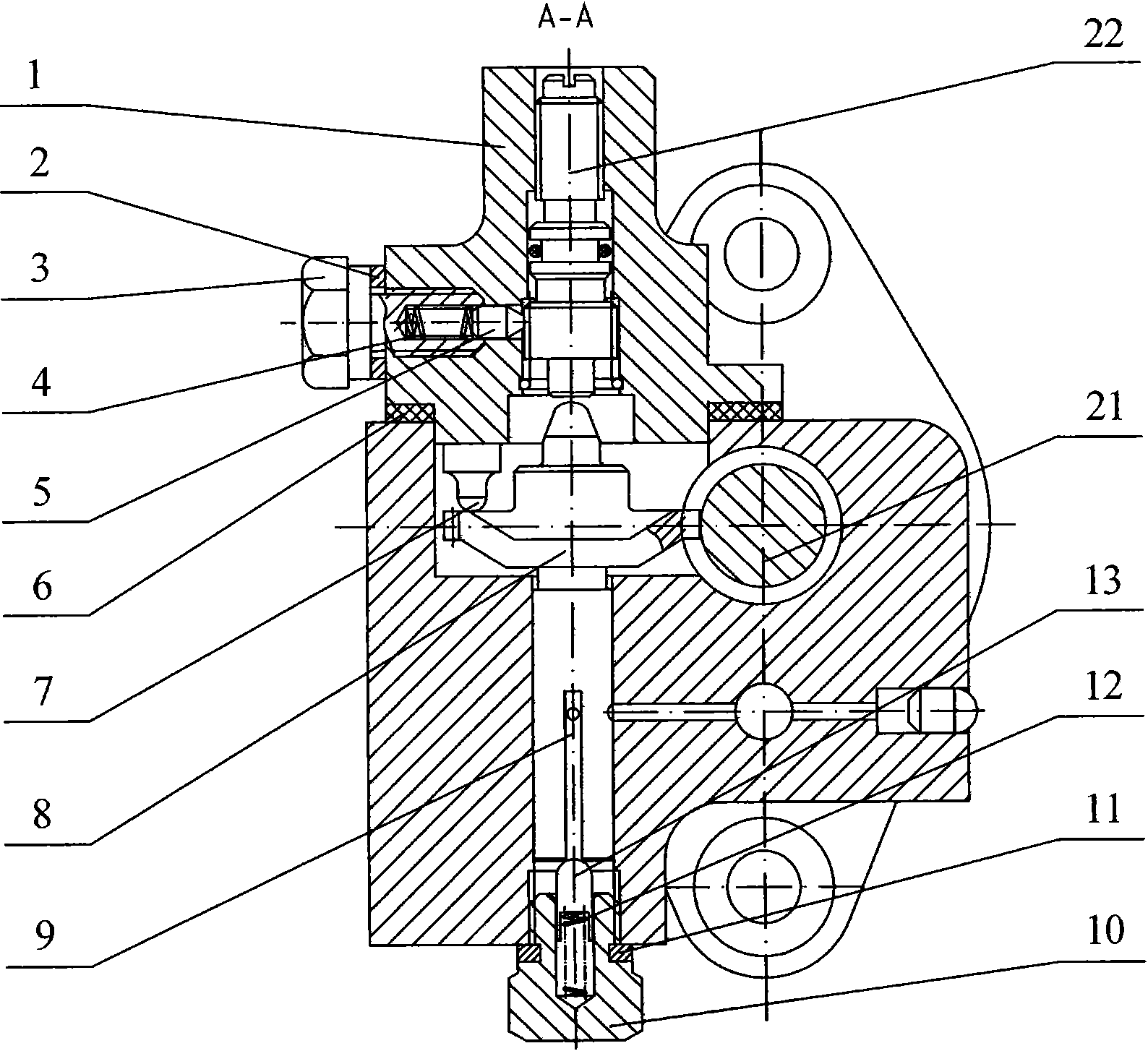

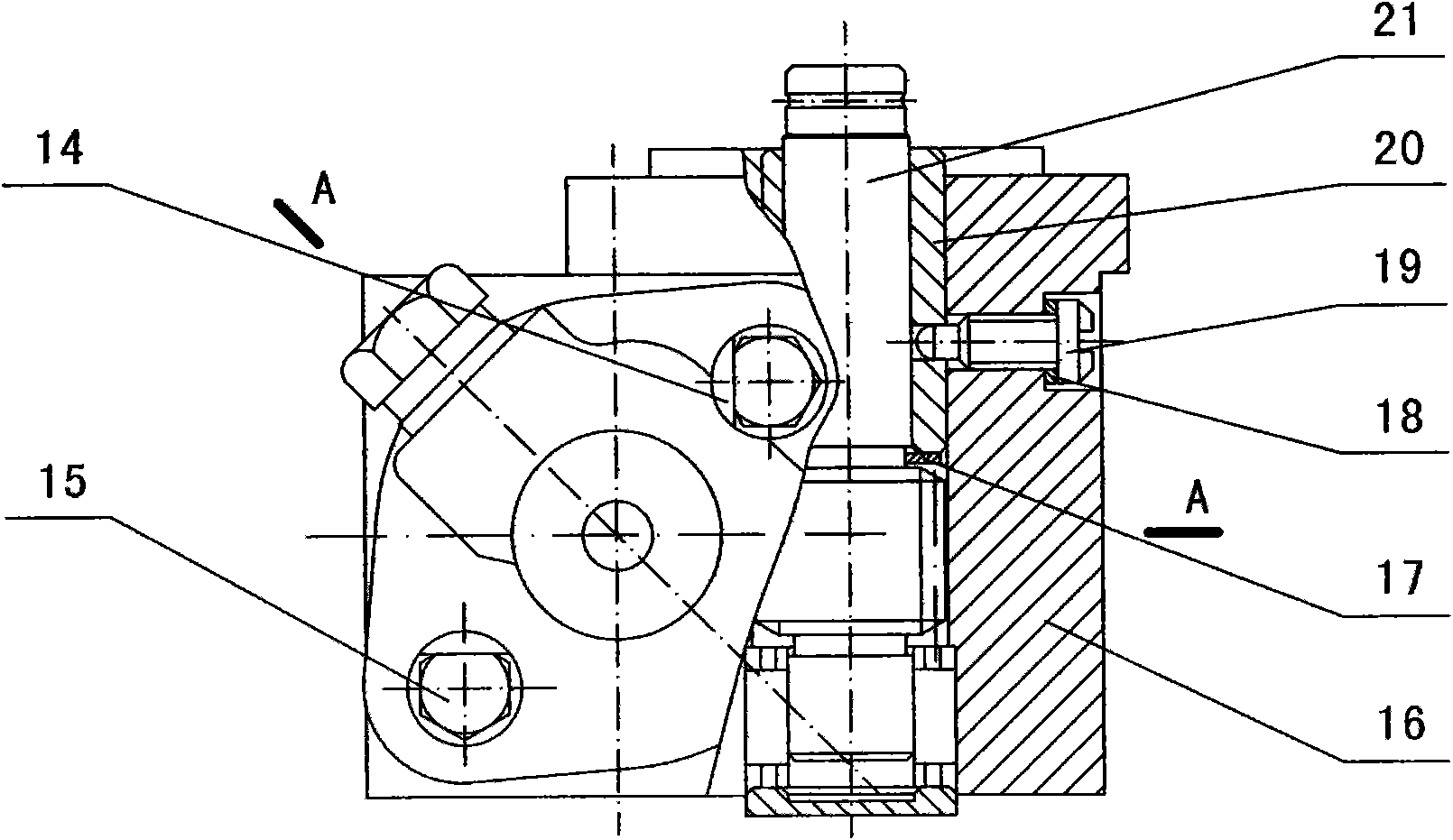

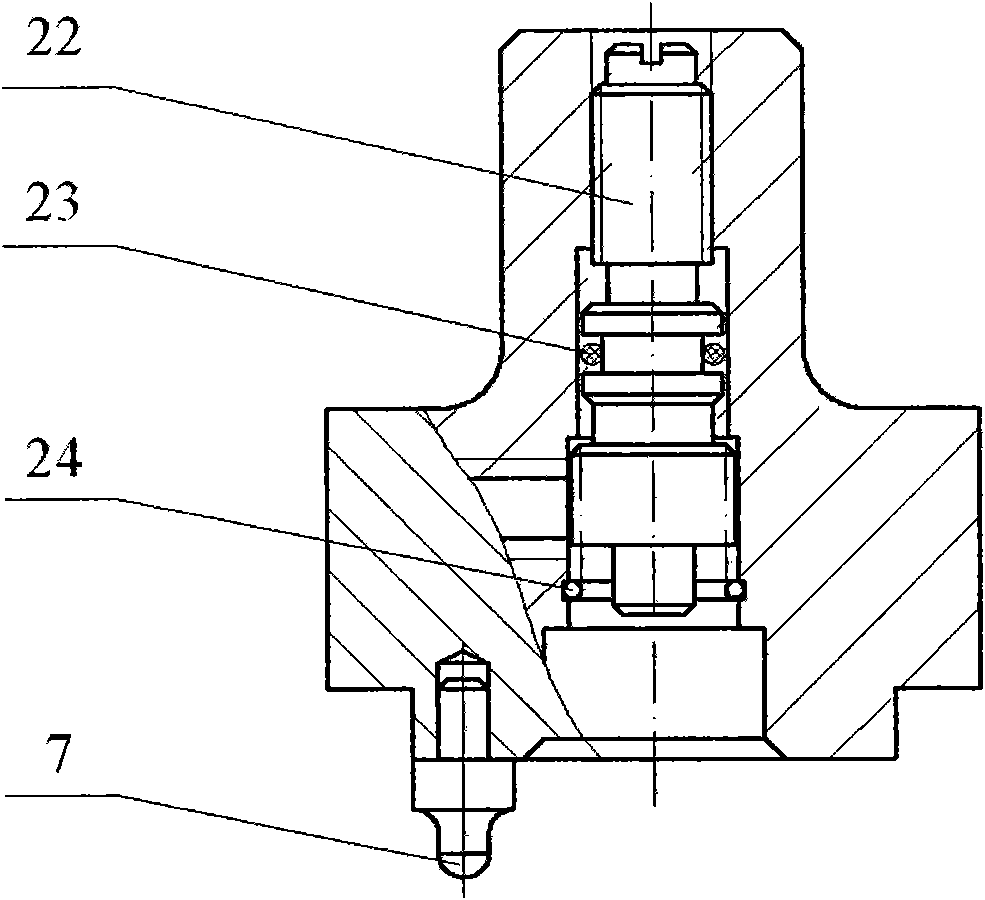

[0022] The diesel valve lubricating device of the present invention mainly includes an oil pumping system, a transmission system and a flow regulating system.

[0023] Such as figure 1 with 2 As shown, the oil pumping system includes a pump body 16 , a plunger 9 , a plunger bottom pin 13 , a return spring 12 and a limit screw 10 . Wherein, the plunger 9 is placed on the plunger bottom pin 13, and the tail of the plunger bottom pin 13 is covered with a return spring 12, and the head of the plunger bottom pin 13 is pressed against the column by the return spring 12 and the limit screw 10. The lower end face of the plug 9. The above-mentioned plunger 9 , plunger bottom pin 13 and return spring 12 are all accommodated in the pump body 16 , and the stop screw 10 is fixed on the pump body 16 .

[0024] The transmission system includes a wave gear 8 and a shaft gear 21 whose axes are perpendicular to each other and meshed with each other. The wave gear 8 is located on the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com