Venting, self-cleaning and degradable environmental-friendly preservative film and preparation method thereof

A green, environmentally friendly, fresh-keeping film technology, applied in flat products, flexible coverings, applications, etc., can solve the problems of the antibacterial properties of the degradable fresh-keeping film, and achieve improved performance, improved performance, and improved tensile strength. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

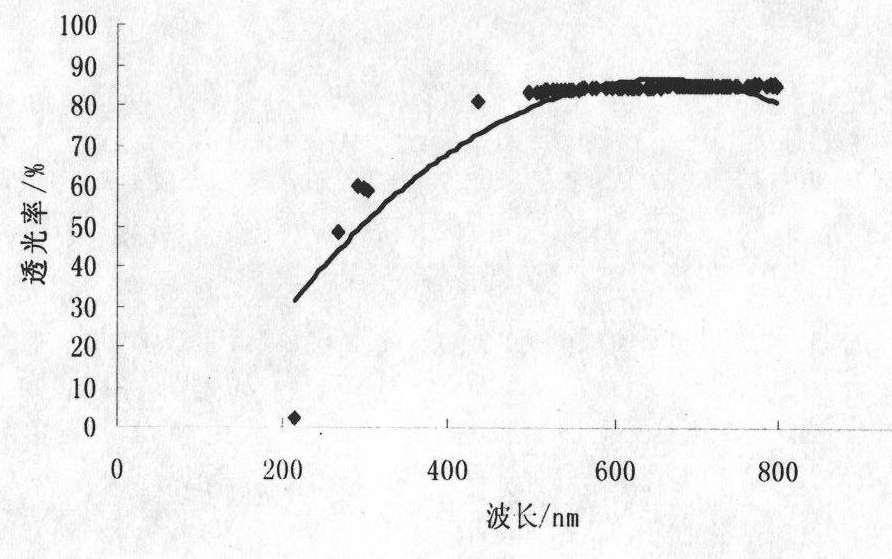

[0042] Add 3.00g of β-cyclodextrin into water, dissolve it with water to 100mL to obtain a 3% aqueous solution of β-cyclodextrin; add 0.020g of nano-sized titanium dioxide to the aqueous solution of β-cyclodextrin and mix, magnetically stir 25min, then put it into an ultrasonic cleaner, ultrasonic frequency 50KHz, water temperature 22°C, oscillate and disperse for 4h until Tyndall phenomenon appears; dissolve 5.0g chitosan in 4.5% acetic acid solution to prepare solution. Mix the β-cyclodextrin aqueous solution and the chitosan acetic acid aqueous solution with the dispersed nano-titanium dioxide in a mass ratio of 1:4, first stir it with a magnetic force for 45 minutes, and then place it in an ultrasonic cleaner for 3.5 hours; For 40 minutes, pour into the mold plate and cast it into a liquid film. In a freeze-drying oven, the temperature is -30°C, the vacuum degree is 5.5KPa, freeze-dry for 3 hours, and after the mixed liquid film is dried, put it in an oven at 70°C and bake...

Embodiment 2

[0044] Add 4.50g of β-cyclodextrin into water, dissolve it with water to 100mL to obtain a 4.5% aqueous solution of β-cyclodextrin; add 0.010g of nano-titanium dioxide to the aqueous solution of β-cyclodextrin and mix, magnetically stir 10min, then put it into an ultrasonic cleaner, ultrasonic frequency 60KHz, water temperature 25°C, oscillate and disperse for 2.5h until Tyndall phenomenon appears; dissolve 3.5g chitosan in 3.5% acetic acid solution to make the mass fraction 3.5% The solution. Mix the β-cyclodextrin aqueous solution and the chitosan acetic acid aqueous solution with the dispersed nano-titanium dioxide in a mass ratio of 1:3, first stir it with a magnetic force for 30 minutes, then place it in an ultrasonic cleaner for oscillating and mixing for 5 hours; let the blended liquid stand still for 30 minutes , injected into the mold plate and cast into a liquid film, in a freeze-drying oven at a temperature of -60°C and a vacuum of 7.0KPa, and freeze-dry for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com