Conductive heating material, floor containing same and manufacture method

A technology of heating material and conductive heating layer, which is applied in the direction of heating element material, heating method, electric heating system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

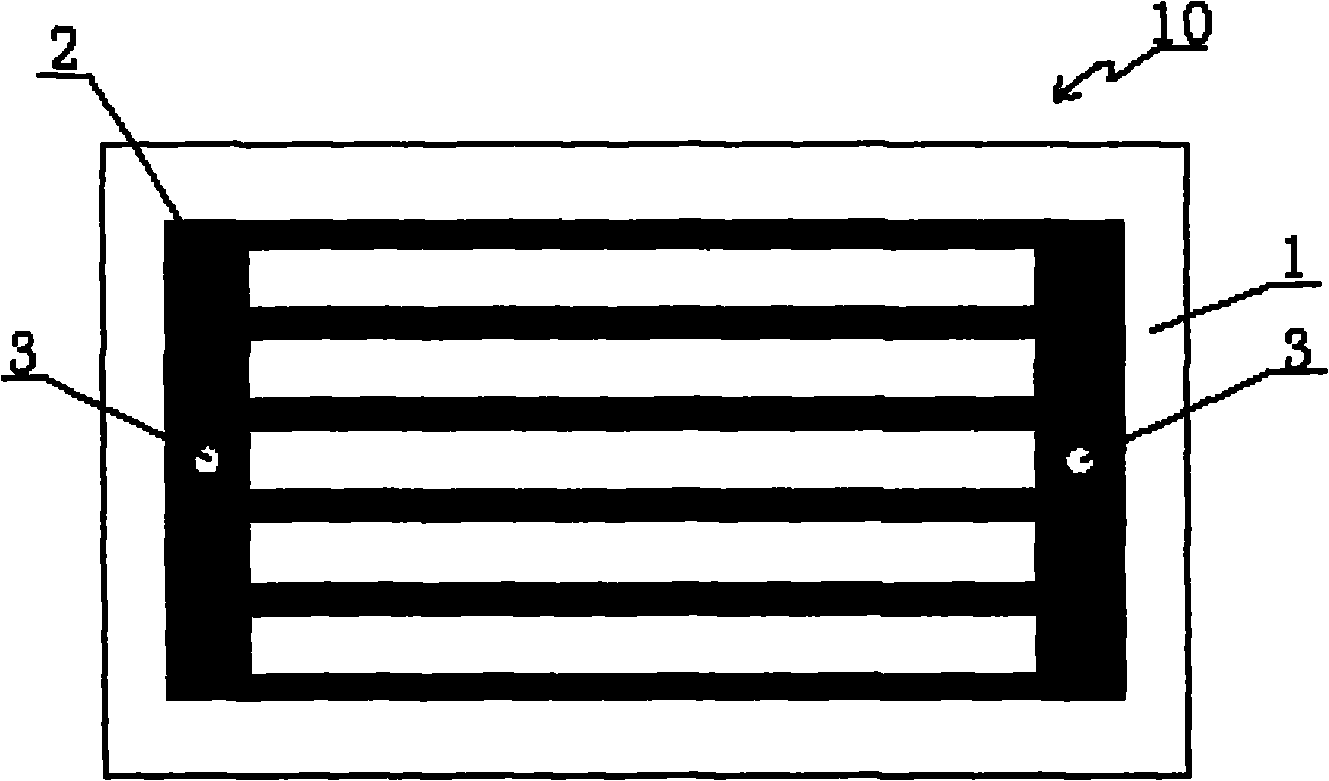

Image

Examples

Embodiment 1

[0051] The paper of conductive heating paper adopts 80g / m 2 kraft paper. The specific formula of conductive heating paint is as follows:

[0052]

Natural graphite (size 300 mesh)

250g

300g

water

700ml

[0053] Firstly, the gelatin is fully dissolved in water, and then the natural graphite is added into the mixture and stirred evenly to make a conductive and heat-generating coating. Then, the above-mentioned paint is evenly printed on the surface of 81cm×12.5cm kraft paper by screen printing in a grid shape, the printed area is 79cm×10.5cm, and the thickness of the conductive heating layer is about 40 microns. Apply insulating glue and cure at 70-90°C. After being fully cured, fix the electrodes on the conductive heating paper with the conductive heating layer. The surface temperature of the conductive heating paper measured after 2, 5, 10, 30, 60, and 120 minutes after turning on the 220V power supply at an ambien...

Embodiment 2

[0056] The paper of conductive heating paper adopts 80g / m 2 kraft paper. The specific formula of conductive heating paint is as follows:

[0057]

Natural graphite (size 300 mesh)

250g

300g

water

700ml

[0058] Firstly, the gelatin is fully dissolved in water, and then the natural graphite is added into the mixture and stirred evenly to make a conductive and heat-generating coating. Then, the above-mentioned paint is evenly printed on the surface of 81cm×12.5cm kraft paper by screen printing in a grid shape, the printed area is 79cm×10.5cm, and the thickness of the conductive heating layer is about 80 microns. Apply insulating glue and cure at 70-90°C. After being fully cured, fix the electrodes on the conductive heating paper with the conductive heating layer. The surface temperature of the conductive heating paper measured after 2, 5, 10, 30, 60, and 120 minutes after turning on the 220V power supply at an ambien...

Embodiment 3

[0061] The paper of conductive heating paper adopts 80g / m 2 kraft paper. The specific formula of conductive heating paint is as follows:

[0062]

Natural graphite (size 300 mesh)

250g

gelatin

300g

water

700ml

[0063] Firstly, the gelatin is fully dissolved in water, and then the natural graphite is added into the mixture and stirred evenly to make a conductive and heat-generating coating. Then, the above-mentioned coating is evenly printed on the surface of 81cm×12.5cm kraft paper by screen printing in a grid shape, the printed area is 79cm×10.5cm, and the thickness of the conductive heating layer is about 120 microns. Apply insulating glue and cure at 70-90°C. After being fully cured, fix the electrodes on the conductive heating paper with the conductive heating layer. The surface temperature of the conductive heating paper measured after 2, 5, 10, 30, 60, and 120 minutes after turning on the 220V power supply at an amb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com