Tunable laser

A technology for tuning lasers and tuning filters, applied to lasers, laser devices, laser components, etc., can solve problems such as unstable performance, slow tuning speed, and poor anti-interference performance, and achieve fast tuning speed, easy assembly, and fast tuning effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] Preferred specific embodiments of the tunable laser are described in detail below.

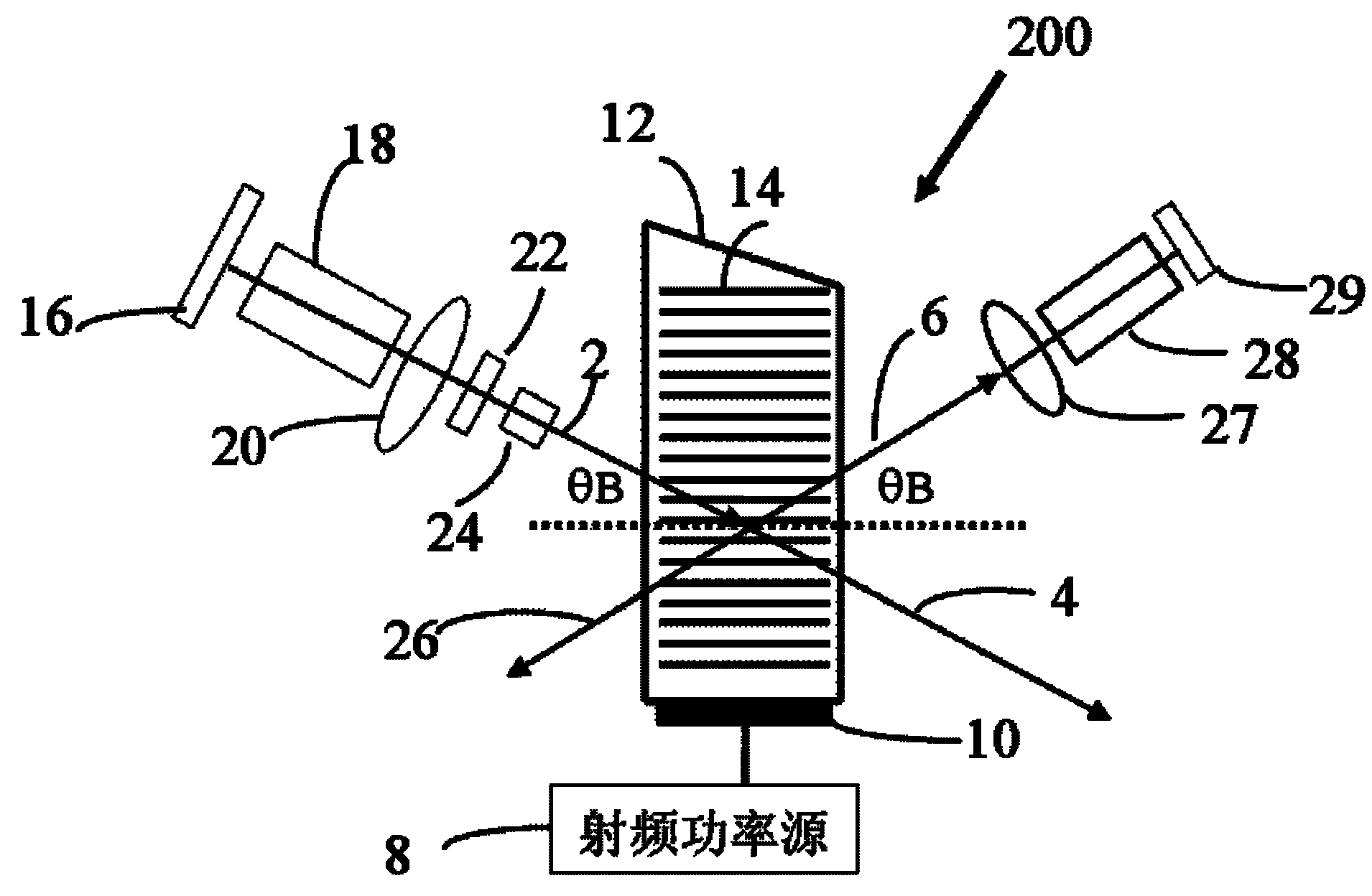

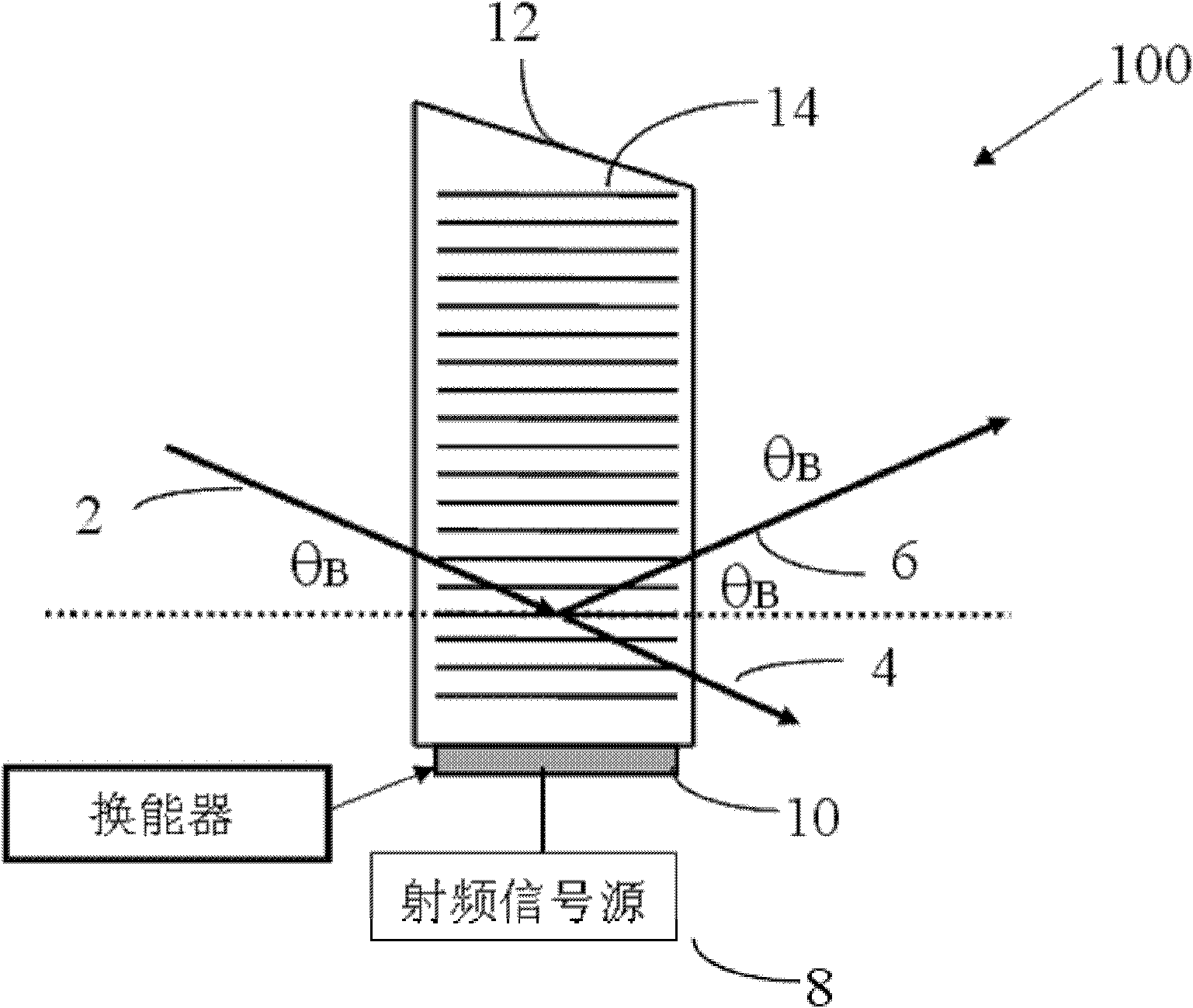

[0044] Acousto-optic tunable filter, as shown in Figure 1. The acousto-optic tunable filter 100 includes a radio frequency power source 8 , an acousto-optic transducer 10 and an acousto-optic crystal 12 .

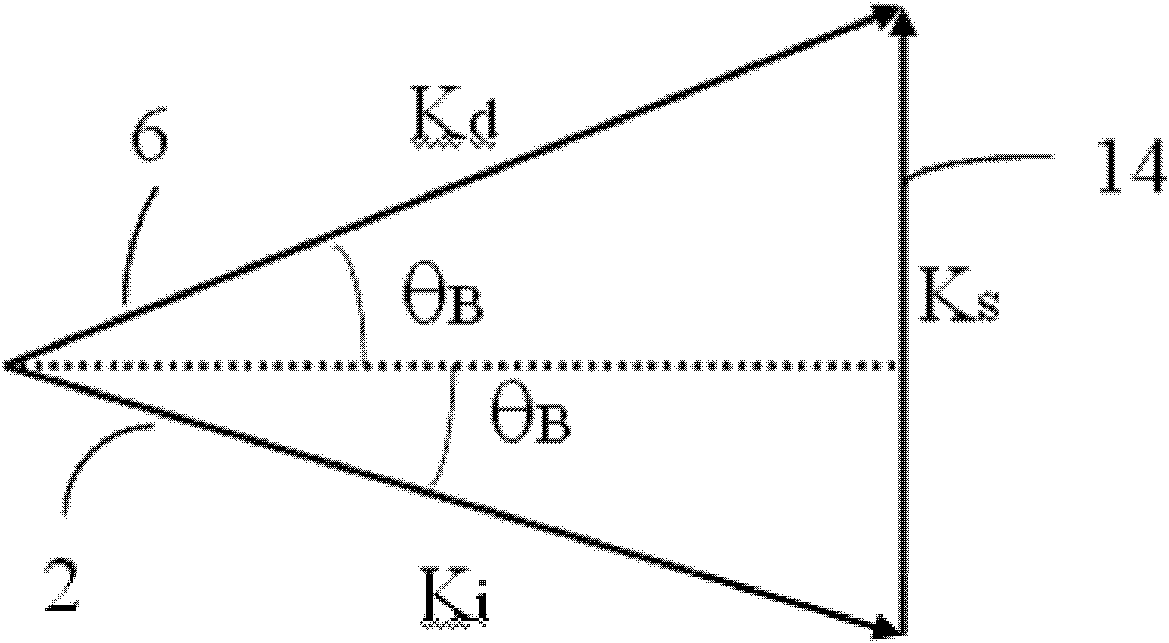

[0045] There are two types of acousto-optic tunable filters: collinear and non-collinear. Among them, the non-collinear type includes isotropic Bragg diffraction type and non-paraxial anisotropic Bragg diffraction type. Among them, the non-paraxial anisotropic Bragg diffraction type, as discussed in several other US patents, has more practical application value because of its narrow diffraction bandwidth.

[0046] In a specific implementation, the acousto-optic crystal 12 is an anisotropic birefringent crystal, which is also required for narrow ban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com