Full-automatic charging and stoking device

A fully automatic, feeding device technology, applied in the direction of descaling devices, furnaces, furnace components, etc., can solve the problems of low automation and large operating space occupation, and achieve the effect of realizing automatic control, reducing labor intensity and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principle of the full-automatic feeding and pounding device of the present invention is that by setting a ring-shaped fixed track above the operating platform of the smelting furnace, the whole pounding machine is suspended on the ring-shaped fixed track, and at the same time, a unified hydraulic control system is used to control the ring-shaped ring of the pounding machine. Walking and various furnace and feeding actions, so as to realize automatic operation and do not occupy operating space.

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

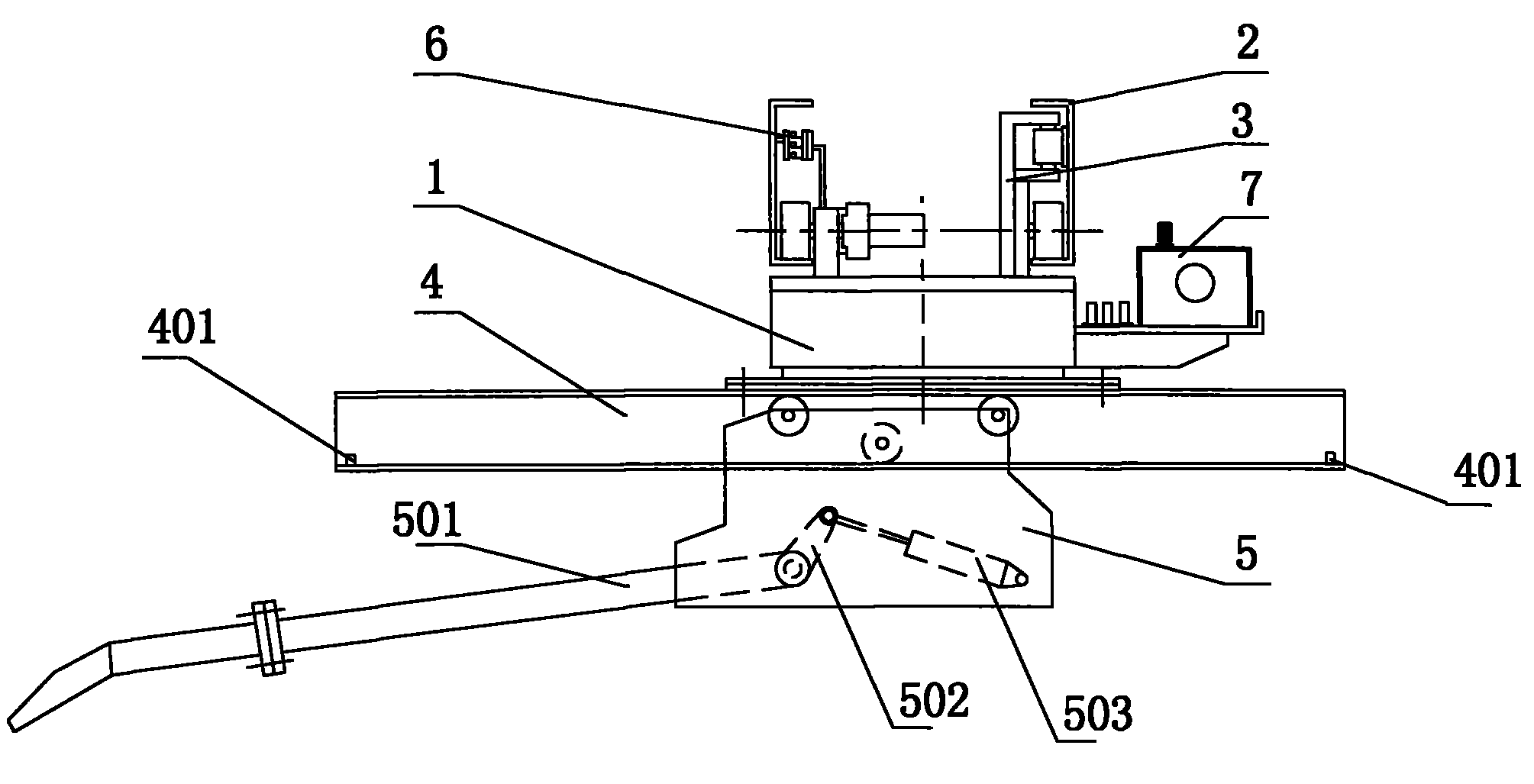

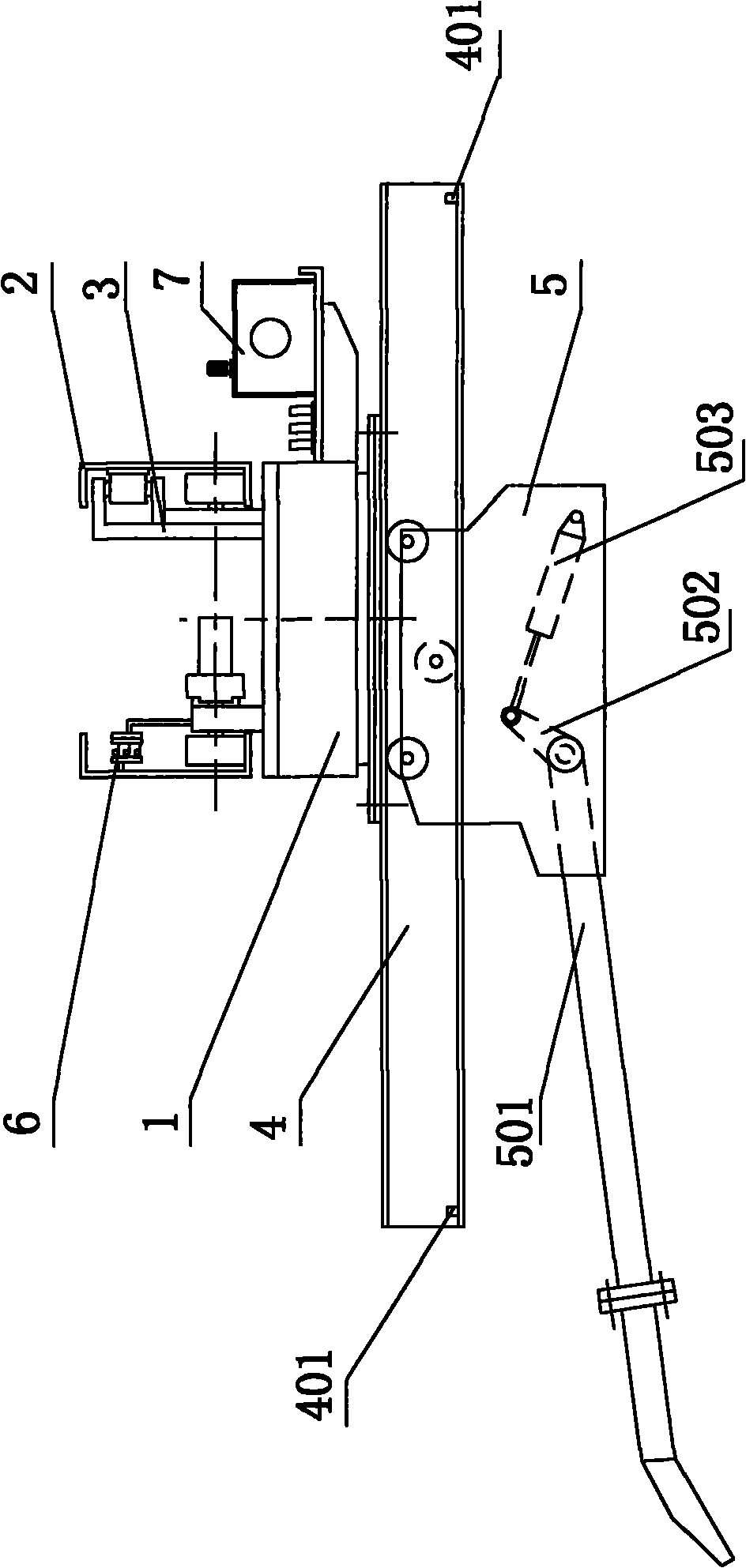

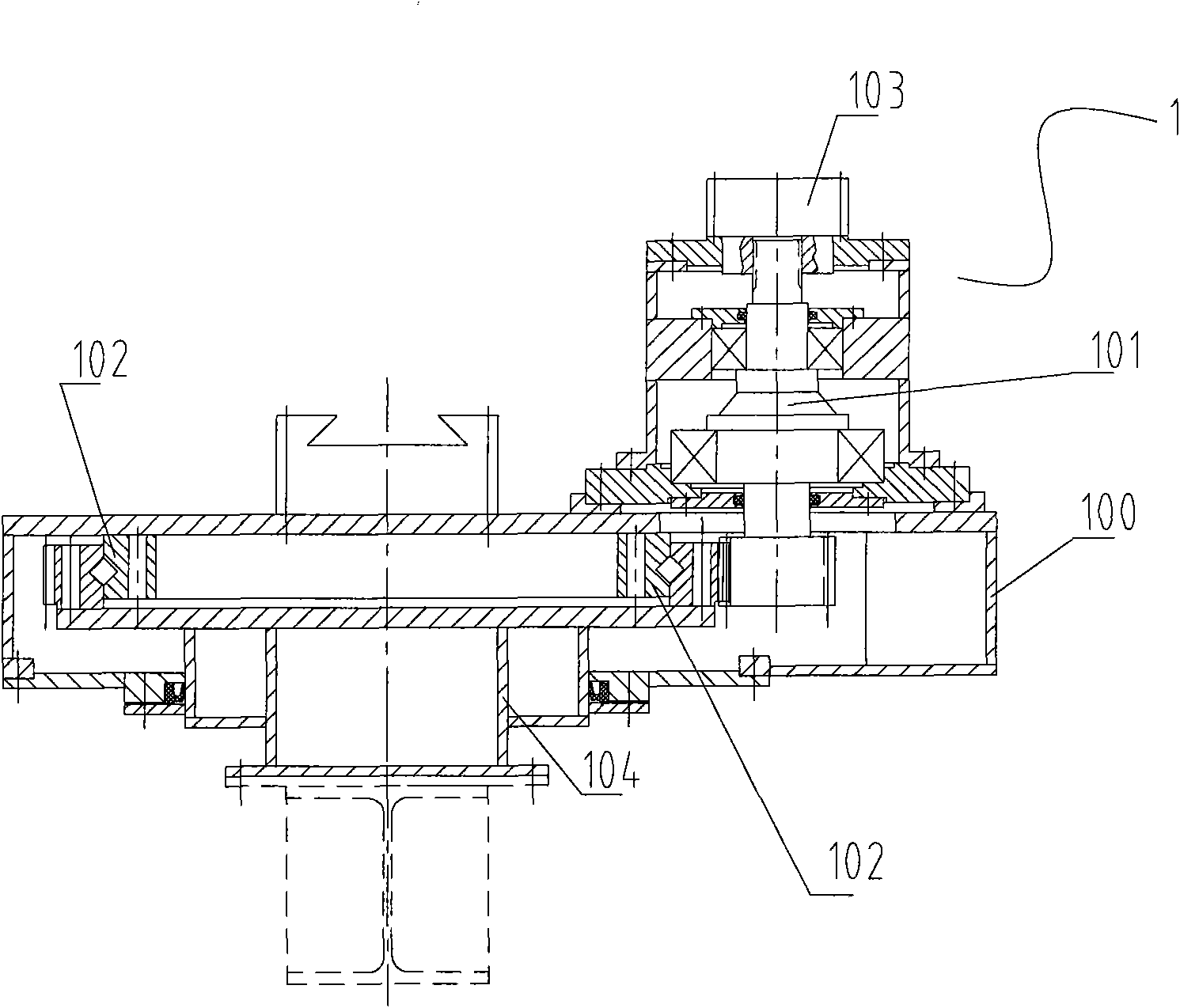

[0025] Referring to Fig. 1, it is a schematic structural representation of the automatic feeding and pounding furnace device of the present invention. As can be seen from this figure, the full-automatic feeding and pounding furnace device of the present invention includes a pounding machine and an annular fixed track 2 that is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com