Construction method for replacing intermediate furnace body of blast furnace

A construction method and a technology in the middle section, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as project cost waste and construction period extension, and achieve the effect of reducing project costs, reducing maintenance investment, and ensuring replacement construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

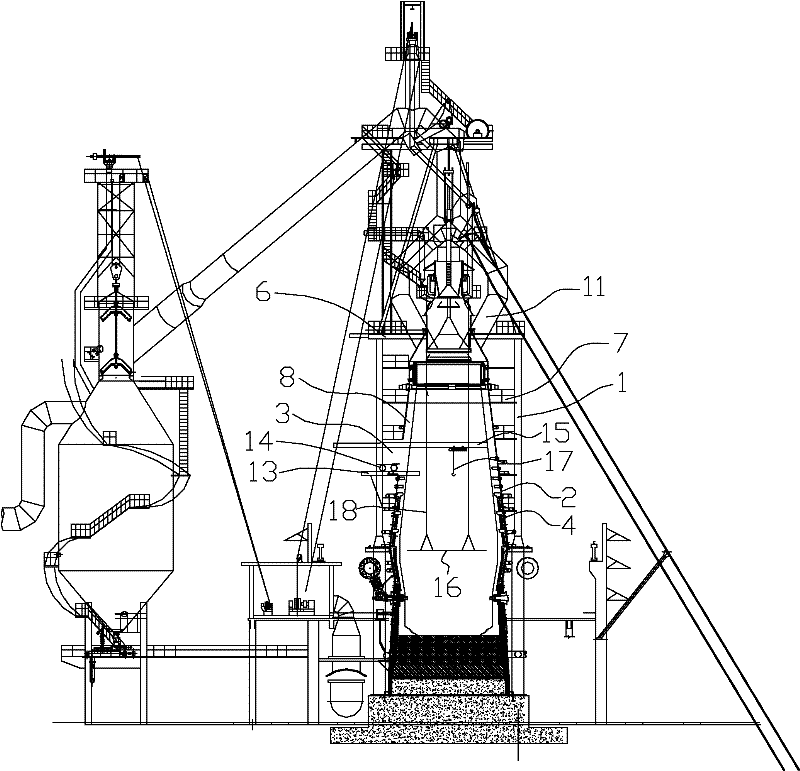

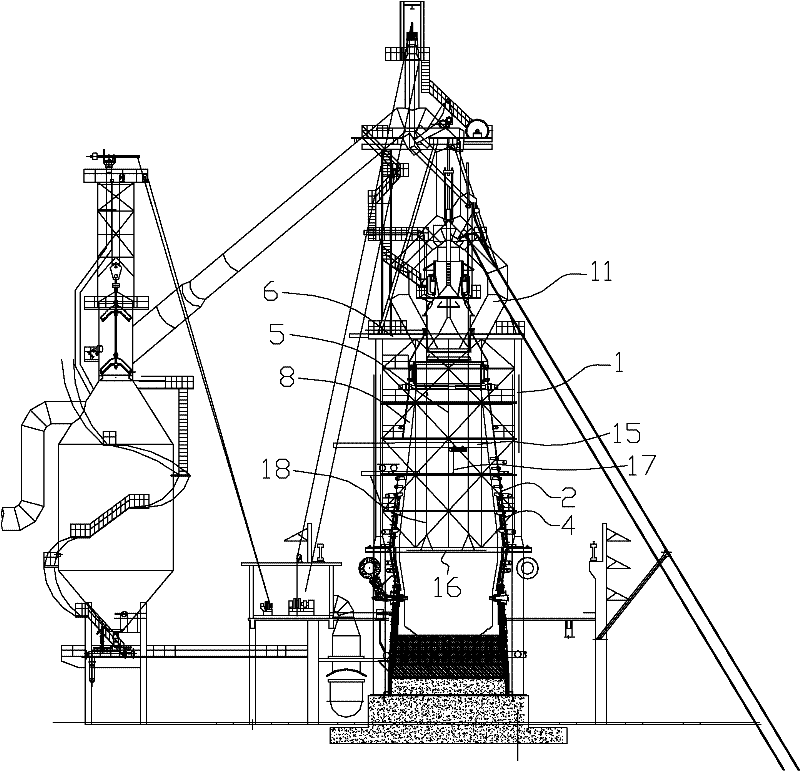

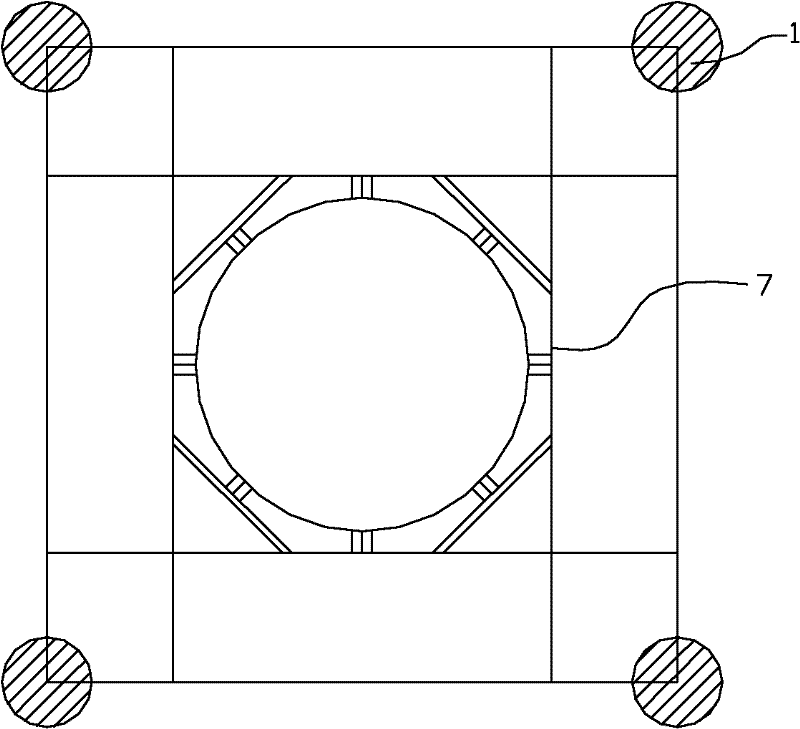

[0032] Such as Figure 1 to Figure 5 As shown, the blast furnace middle section furnace body replacement construction method of the present invention is characterized in that comprising the following steps:

[0033] a. Carry out load calculation and inspection on the blast furnace frame 1; if the blast furnace frame 1 can meet the load-bearing requirements without reinforcement, that is to say, the blast furnace frame 1 itself is safe and reliable after load calculation and actual quality inspection of the blast furnace structure , then go directly to step b. On the contrary, if the blast furnace frame 1 cannot meet the bearing requirements, the blast furnace frame 1 should be reinforced before step b. The main purpose of reinforcement is to make the blast furnace frame 1 able to bear the blast furnace damaged shaft after the middle section of the dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com