Fume condensed-water flue-dust conveyance system of supercharged oxygen-enriched coal-fired boiler

A coal-fired boiler and condensate technology, applied in the field of ash conveying system, can solve the problems of large power consumption, water consumption, easy scaling, etc., and achieve the effect of saving electric energy and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

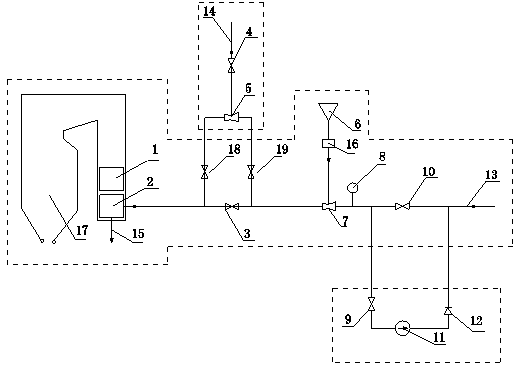

[0012] See attached figure 1 , The composition of the present invention includes a high-pressure condensed water recovery part, a coal ash injection part and ash conveying main pipeline. The high-pressure condensed water recovery part is composed of a pressurized combustion furnace 17, a dust collector 1, a condenser 2 and a flue 15. The dust collector 1 is connected to the exhaust port of the pressurized combustion furnace 17, and the condenser 2 is arranged After the dust remover 1; the described coal ash ejection part is made up of ash funnel 6, powder discharge machine 16 and coal ash ejector 7, and the powder discharge machine 16 is arranged behind the dust funnel 6, and its outlet is connected with the dust funnel 6. The coal ash ejector 7 is connected at one end tapering, and the inlet of the coal ash ejector 7 is connected with the main ash conveying pipeline; The pressure gauge 8 is composed of the first regulating valve 3 arranged after the condenser 2, the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com