Zinc oxide powder desulfurization control device and method based on online monitoring data interlocking

A technology of zinc oxide powder and monitoring data is applied in the field of zinc oxide powder desulfurization control device based on online monitoring data interlocking, which can solve the problem that the desulfurization process cannot be monitored and controlled dynamically in real time, so as to reduce the investment and maintenance investment of testing equipment, simplify the Operational logic, the effect of reducing the difficulty of configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

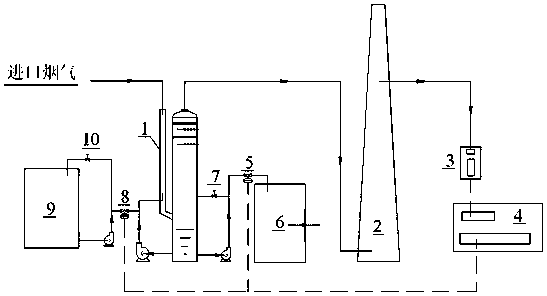

[0040]Specific example: the flue gas of the 140,000 t / a acid-making system of a certain factory adopts the desulfurization method of zinc oxide powder, and the flue gas flow rate is 50,000m 3 / h, SO before flue gas desulfurization 2 The concentration value is 2000~3000 mg / m 3 , the local emission limit is 400 mg / m 3 .

[0041] According to the data from the trial production, the zinc oxide powder slurry with a solid content of 15% (mass percentage) was prepared as the absorbing liquid for desulfurization;

[0042] The flue gas from the acid production enters the absorption tower and reacts with the absorption liquid for desulfurization, and the tail gas is directly discharged into the chimney, and the tail gas SO 2 The concentration is detected in real time by the online monitor, and the detection data is transmitted to the central control system;

[0043] In the central control system, set the interlocking conditions for the start and close of the liquid discharge pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com