Method and device for extracting prickly ash seed oil from prickly ash seeds

A technology of Zanthoxylum bungeanum seed oil and Zanthoxylum bungeanum seed, applied in the direction of fat oil/fat production, fat oil/fat refining, fat generation, etc., can solve the problems of limited raw material processing, low oil yield, high production cost, etc.

Active Publication Date: 2010-08-25

甘肃省轻工研究院有限责任公司

View PDF3 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The physical method is commonly used to extract by pressing. The pressing method uses mechanical force to squeeze the embryo to produce oil. The process route is simple, and the product is easily polluted during the production process. It contains many impurities, microorganisms and heavy metals are easy to exceed the standard, and the oil yield is low. The amount of residual oil in oil residue is high; chemical methods usually use organic solvents to extract oil, and the commonly used organic solvents are ether, petroleum ether, n-hexane, etc., because the solvents are flammable and explosive, the production safety is poor, and the product has solvent residues, which affects its quality and quality, which also affects its application, both methods have obvious disadvantages

Due to the high cost of equipment design and manufacturing and operating costs for supercritical CO2 extraction of vegetable oils, only 3000L supercritical extraction equipment can be produced in China at present. The amount of raw materials to be processed is limited and the production cost is high. It is mainly used to extract some high value-added products. For Zanthoxylum bungeanum The production cost of products with low added value such as pepper seeds is too high, so it is not suitable to process bulk raw materials such as pepper seeds in industrial production

Method used

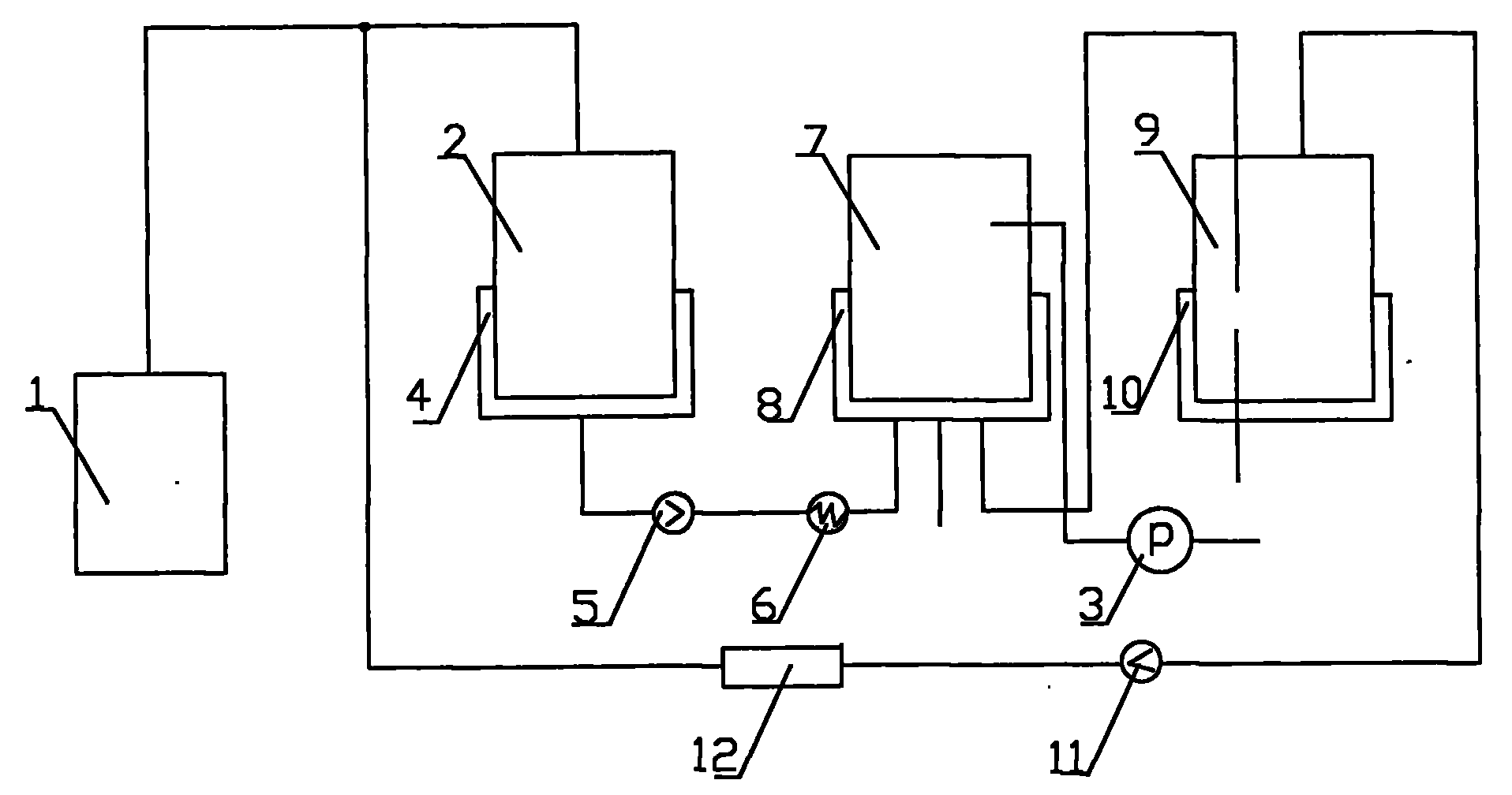

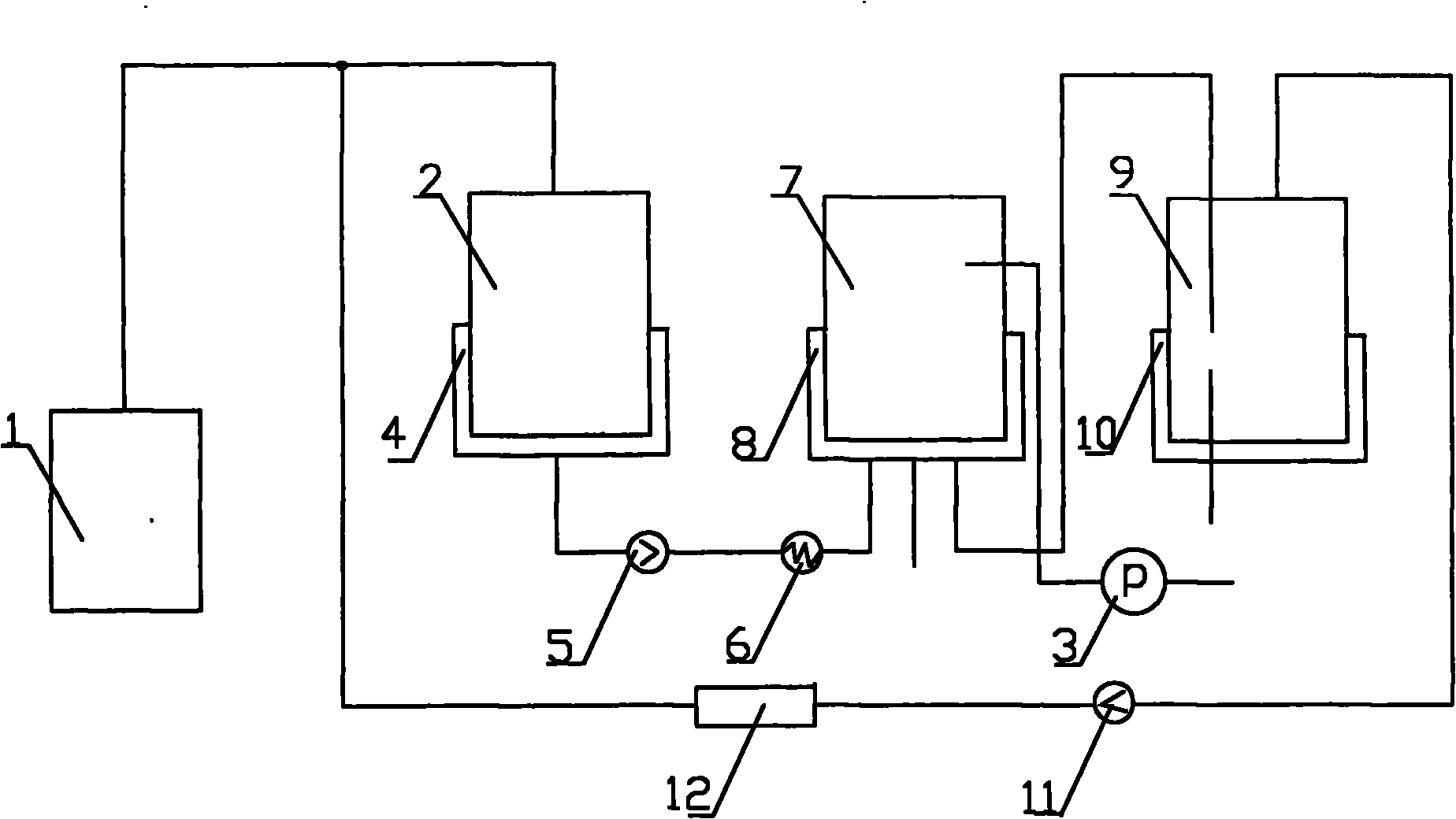

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for extracting grease from oil material, in particular to a method for extracting prickly ash seed oil from prickly ash seeds. The method for extracting prickly ash seed oil from prickly ash seeds is characterized by comprising the following steps of: (1) firstly, drying the prickly ash seeds until the water content is smaller than 13%, and crushing to 40-80 meshes by using a crusher; (2) delivering the dried and crushed prickly ash seeds into an extracting kettle, pumping the vacuum to the pressure below 1*10<4>Pa, and evacuating air in the extracting kettle; (3) then, pumping a tetrafluoroethane solution into the extracting kettle by using a plunger pump until the prickly ash seeds are emerged under the liquid level under the observation of a sight glass; (4) stirring, and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature range is 40-50 DEG C, and the extraction time is 30-45 min each time; (5) depressurizing and raising temperature to evaporate and separate in a separating kettle, wherein the separation pressure range is 0.5-0.1MPa, and the temperature range is 45-50 DEG C; and (6) after subcritical extraction, centrifugally separating and filtering the crude oil through a high-speed centrifuge to obtain the final prickly ash seed oil.

Description

Method and device for extracting pepper seed oil from pepper seeds Technical field: The invention relates to a method for extracting oil from oil plants, in particular to a method for extracting pepper seed oil from pepper seeds. Background technique: Chinese prickly ash (Zanthexylumbungeanum Maxin) belongs to the rue spice plant, and our country has a long history of cultivation and extensive planting. Zanthoxylum bungeanum fruit is generally shelled and eaten as seasoning, and Zanthoxylum bungeanum seed is the main by-product in Zanthoxylum bungeanum production, and its output accounts for more than 50% of Zanthoxylum bungeanum fruit. Zanthoxylum bungeanum contains more than 25% oil, and Zanthoxylum bungeanum oil is rich in unsaturated fatty acids, including 25-32% oleic acid, 18-33% linoleic acid, and 17-24% linolenic acid. More than 80%, it is an excellent health care nutritional oil. It is reported that pepper seed oil has been used in food, medicine and industrial ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11B1/10C11B3/16

Inventor 赵煜赵启政朱刚于长青李文磊

Owner 甘肃省轻工研究院有限责任公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com