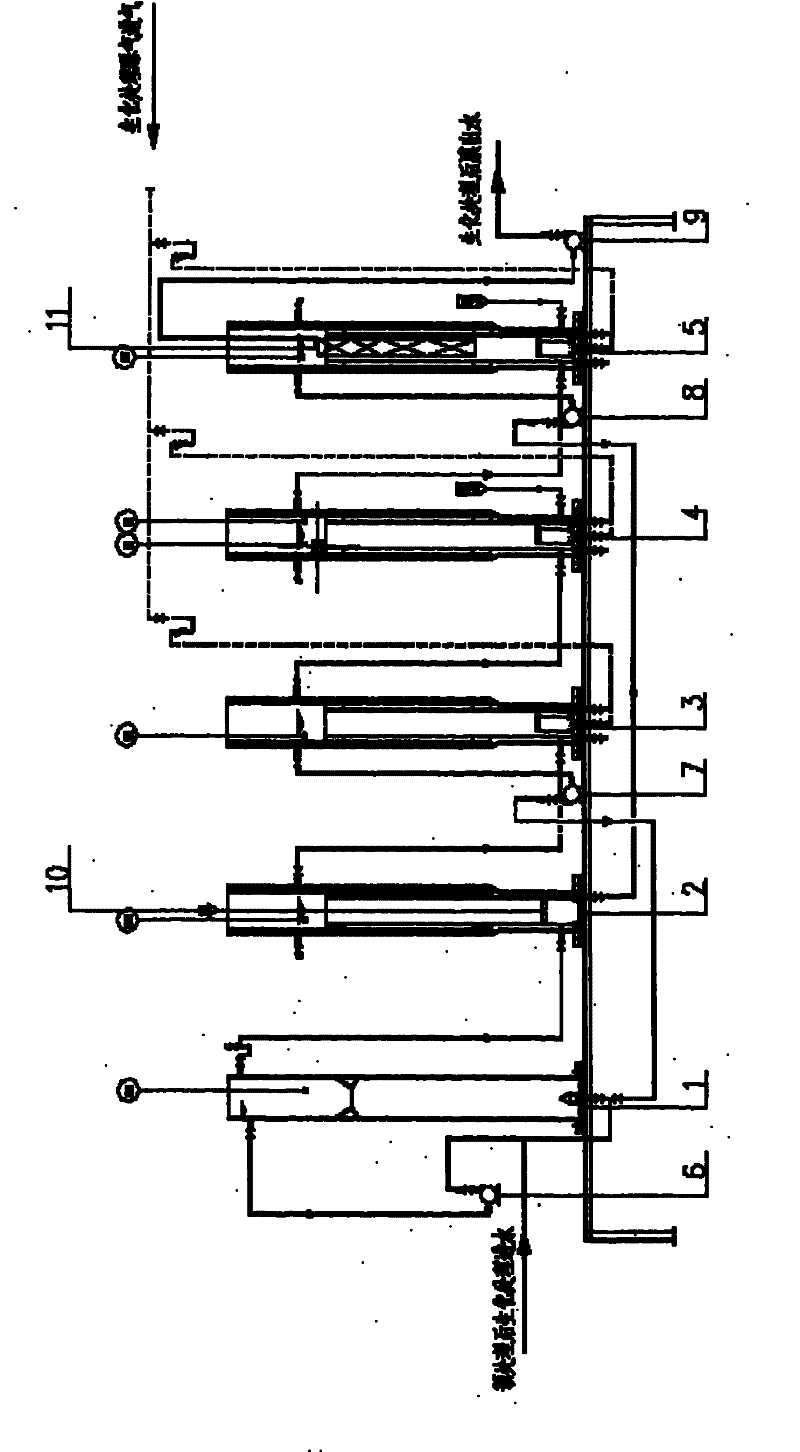

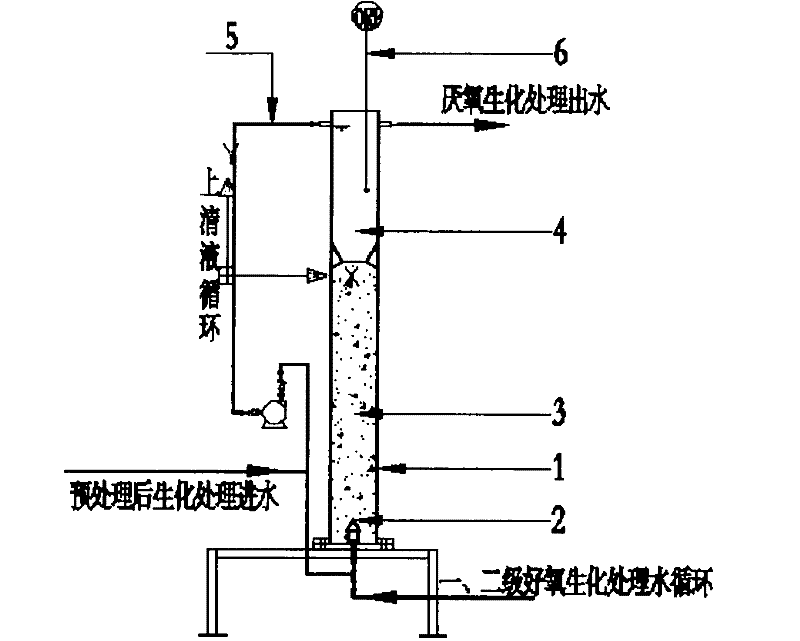

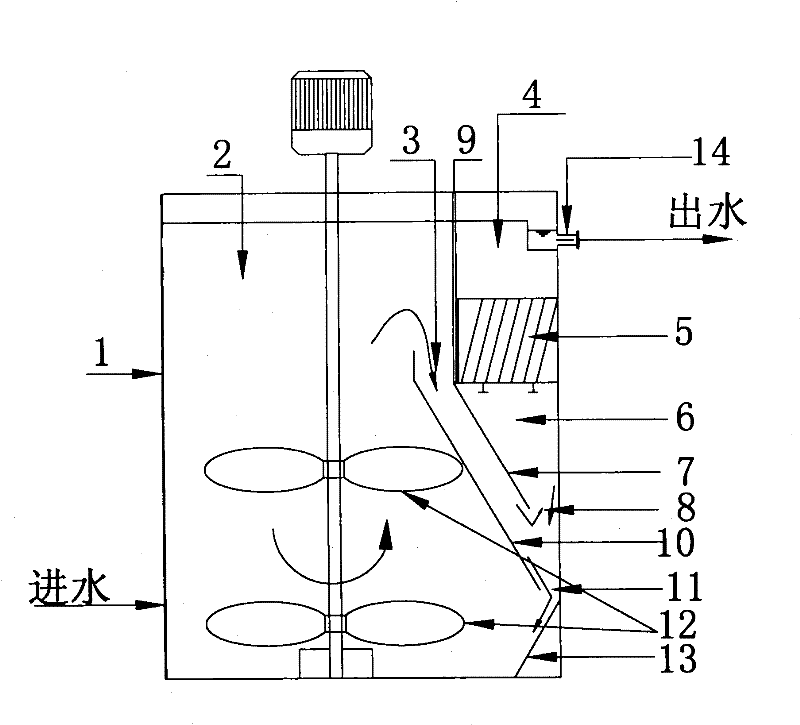

Coal gasification waste water biochemical treatment equipment and method

A technology for coal gasification wastewater and biochemical treatment, applied in chemical instruments and methods, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve the problems of low COD removal rate, ammonia nitrogen removal rate, high investment and operating costs, ammonia nitrogen Adapt to problems such as small scope, to achieve the effect of inhibiting membrane pollution, low sludge load, and good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083]An actual coal gasification wastewater influent COD: 8600mg / l; influent ammonia nitrogen: 893.41mg / l; influent volatile phenol: 1530mg / l; The residence time of the treatment unit is 15 hours, the residence time of the anoxic biochemical treatment unit is 12 hours, the residence time of the primary aerobic biochemical treatment unit is 20 hours, the residence time of the secondary aerobic biochemical treatment unit is 20 hours, and the residence time of the membrane bioreaction unit is 13 hours), The average concentration of activated sludge is: 6000mg / l, the air-water ratio is 100, the pH value has been maintained between 7.2 and 7.7, and the wastewater treatment effect shown in Table 1 has been obtained under the condition of above 20°C.

[0084] Table 1

[0085]

water quality index

raw water

Anaerobic

unit out

water

hypoxic biochemical

processing unit

out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com