Integrated portal lathe bed

A one-piece bed technology, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems that the accuracy cannot be maintained for a long time, affects the overall accuracy of the machine tool, and the production cycle is long, so as to achieve convenient operation and design Humanized design Human nature, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

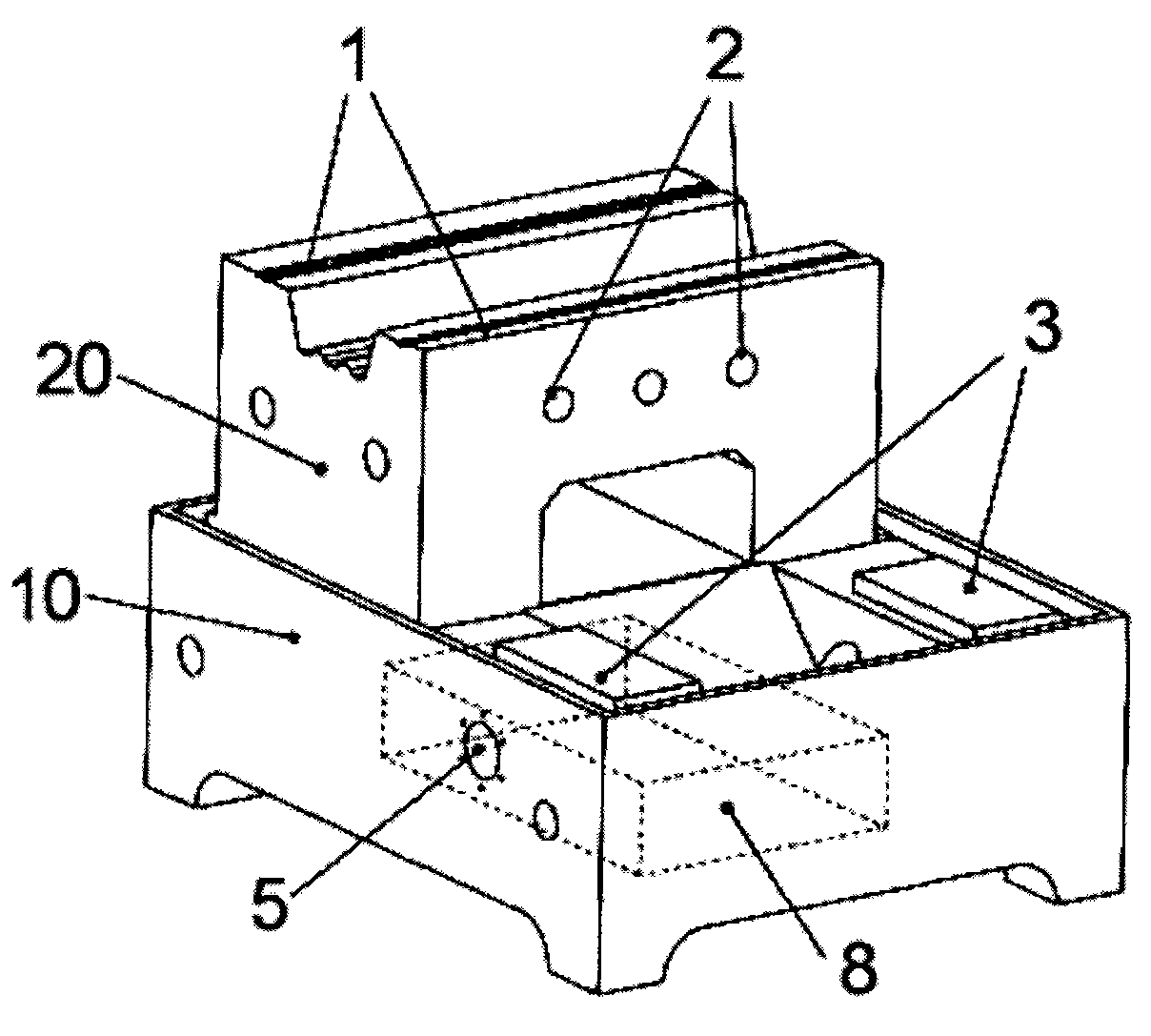

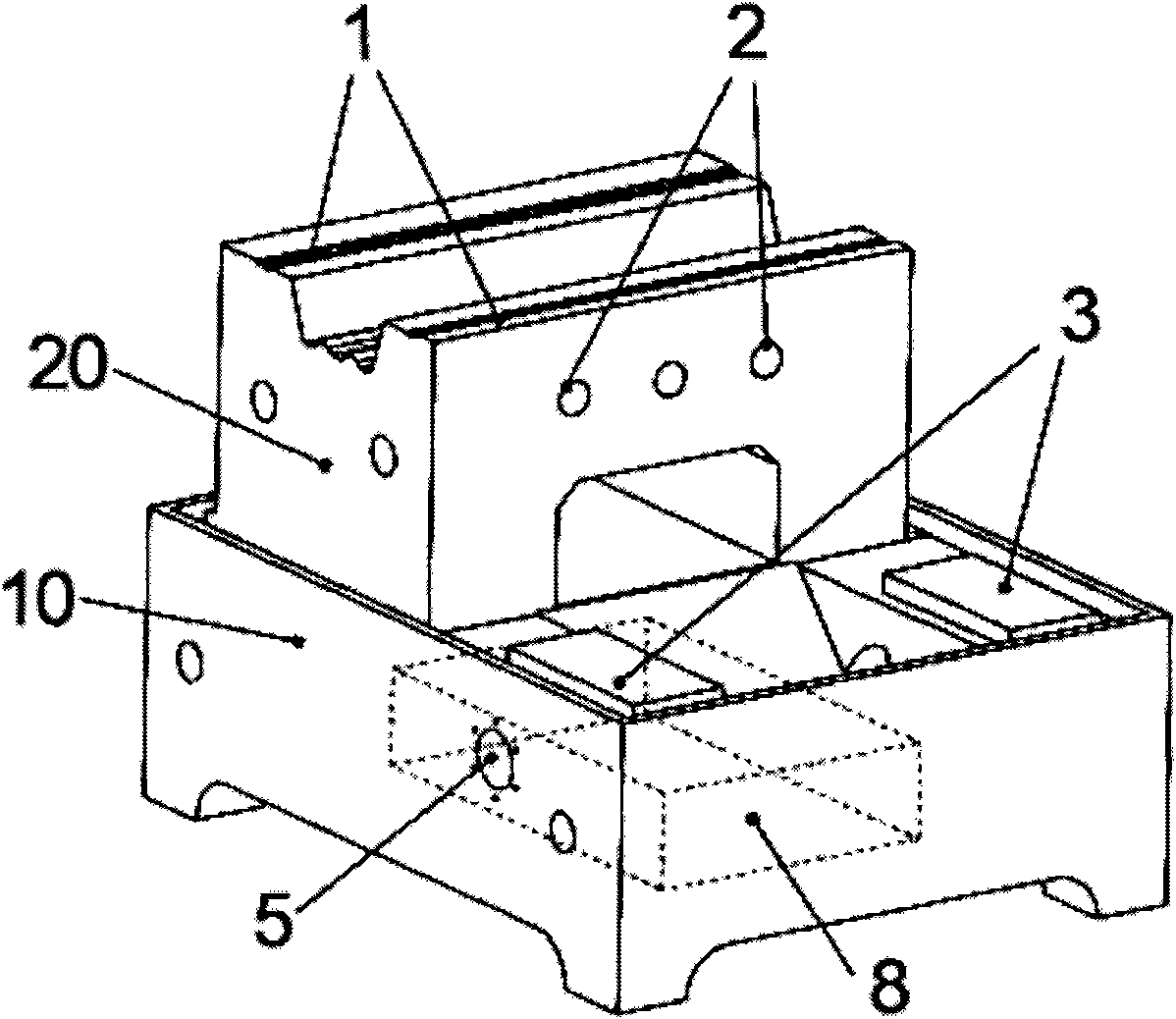

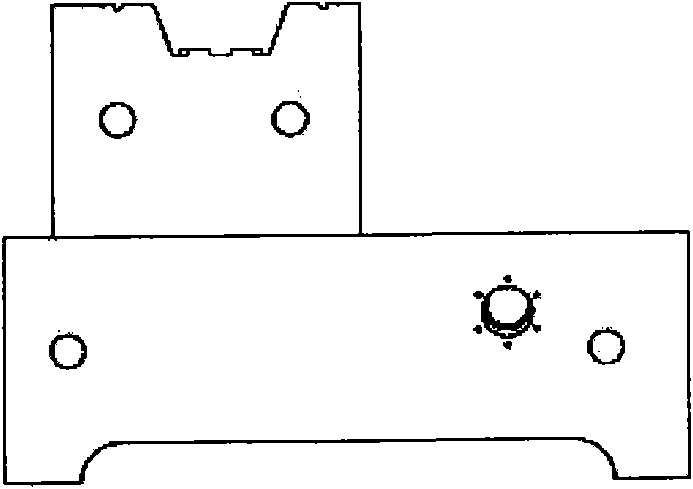

[0026] Embodiment: as shown in Fig. 1, Fig. 2, Fig. 3, a kind of one-piece gantry bed, it comprises bed body 10, gantry frame 20, and gantry frame 20 is positioned at the top of bed body 10, bed body 10 and The portal frame 20 is combined into a whole.

[0027] The upper end of the gantry frame 20 is provided with two X-axis guide rail mounting surfaces 1 in the X direction. An X-axis component installation groove for installing X-axis components is provided between the installation surfaces 1 of the two X-axis guide rails. Make the upper part of the gantry frame 20 a U-shaped structure in the side direction (refer to FIG. 2 ).

[0028] After the machine tool is installed, the X-axis components can be completely located on the lower side of the X-axis guide rail installation surface 1, which is beneficial to reduce the height of the machine tool, reduce the space of the whole machine, and improve the rigidity of the machine tool.

[0029] The gantry 20 is provided with a too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com