Method for preparing silver nano sheet self-assembling material

A technology of silver nanosheets and self-assembly is applied in the field of preparation of silver nanosheet self-assembly materials, which can solve the problems of lack of adjustability and limitation of morphology, and achieve controllable structure and morphology, stable particle spacing, and particle size. The effect of narrow diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

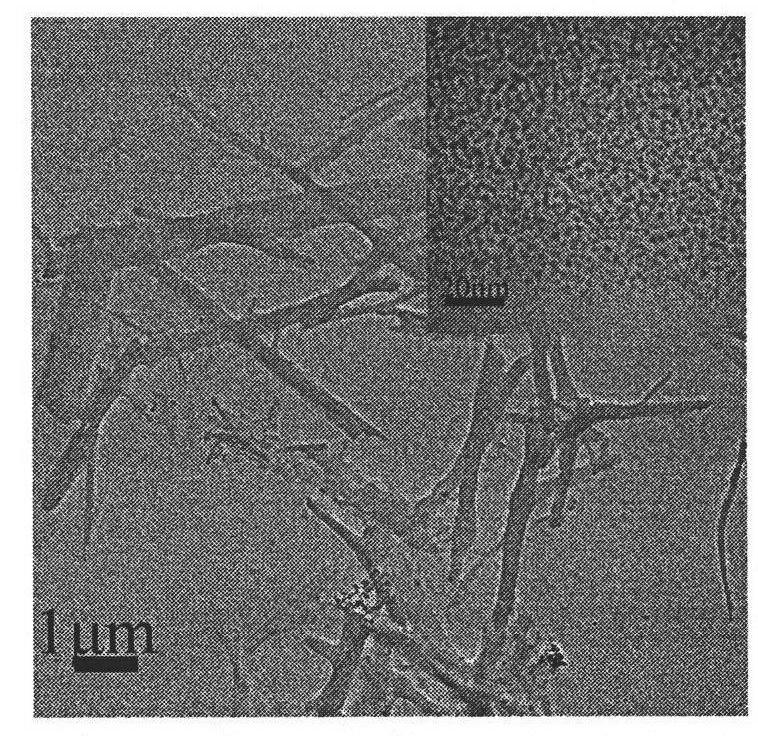

[0028] Add 72 μl of 0.2M AgNO to a beaker containing 5ml of 0.04M stearic acid in MMA solution 3 Aqueous solution, stirred at room temperature to form reverse micellar solution A. In addition, add 72 μl of 0.2M NaBH to another beaker containing 5ml of 0.04M stearic acid in MMA solution 4 Aqueous solution, stirred at room temperature to form reverse micellar solution B. Then, the reverse micelles B were slowly added to the reverse micelles A solution under magnetic stirring and reacted for 1 h. Centrifuge the resulting reaction solution at a speed of 2500 to 5000 rpm, remove the supernatant, wash with deionized water, centrifuge at a speed of 2500 to 5000 rpm, remove the supernatant, and repeat washing 1 to 3 times, then Washing with ethanol, centrifuging at a rotational speed of 2500-5000 rpm, removing the supernatant, repeating washing 2-3 times, extracting and dispersing the precipitate with ethanol to obtain curly silver nanosheet self-assembly. The molar ratio of water ...

Embodiment 2

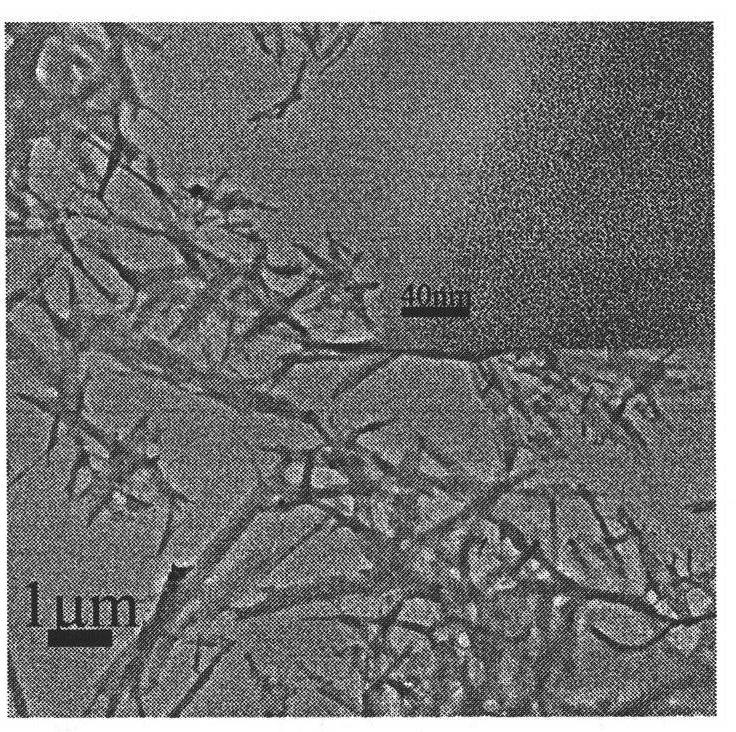

[0030] Add 144 μl 0.2M AgNO to a beaker containing 5ml 0.04M stearic acid in MMA solution 3 Aqueous solution, stirred at room temperature to form reverse micellar solution A. In addition, add 144 μl 0.2M NaBH to another beaker containing 5ml 0.04M stearic acid in MMA solution 4 Aqueous solution, stirred at room temperature to form reverse micellar solution B. Then, the reverse micelles B were slowly added to the reverse micelles A solution under magnetic stirring and reacted for 1 h. Centrifuge the resulting reaction solution at a speed of 2500 to 5000 rpm, remove the supernatant, wash with deionized water, centrifuge at a speed of 2500 to 5000 rpm, remove the supernatant, and repeat washing 1 to 3 times, then Washing with ethanol, centrifuging at a rotational speed of 2500-5000 rpm, removing the supernatant, repeating washing 2-3 times, extracting and dispersing the precipitate with ethanol to obtain curly silver nanosheet self-assembly. The molar ratio of water in the raw...

Embodiment 3

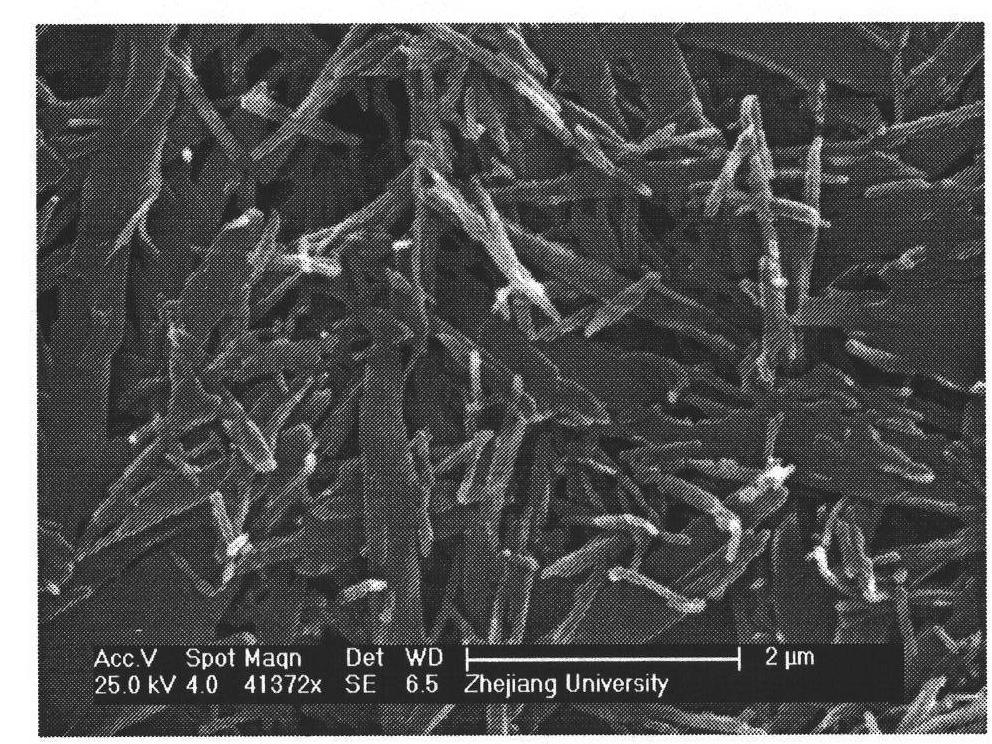

[0032] Add 216 μl of 0.2M AgNO to a beaker containing 5ml of 0.04M stearic acid in MMA solution 3 Aqueous solution, stirred at room temperature to form reverse micellar solution A. In addition, add 216 μl 0.2M NaBH to another beaker containing 5ml 0.04M stearic acid in MMA solution 4Aqueous solution, stirred at room temperature to form reverse micellar solution B. Then, the reverse micelles B were slowly added to the reverse micelles A solution under magnetic stirring and reacted for 1 h. Centrifuge the resulting reaction solution at a speed of 2500 to 5000 rpm, remove the supernatant, wash with deionized water, centrifuge at a speed of 2500 to 5000 rpm, remove the supernatant, and repeat washing 1 to 3 times, then Washing with ethanol, centrifuging at a rotational speed of 2500-5000 rpm, removing the supernatant, repeating washing 2-3 times, extracting and dispersing the precipitate with ethanol to obtain curly silver nanosheet self-assembly. The molar ratio of water in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com