Steam-generating device

A technology of a steam generating device and a steam-water separator, which is applied in steam generation, steam generation methods, lighting and heating equipment, etc., can solve problems such as unsatisfactory steam-water separation effect, waste of water resources and energy, and unsatisfactory food taste, etc., to achieve Improve the taste of food, save energy, reduce the effect of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

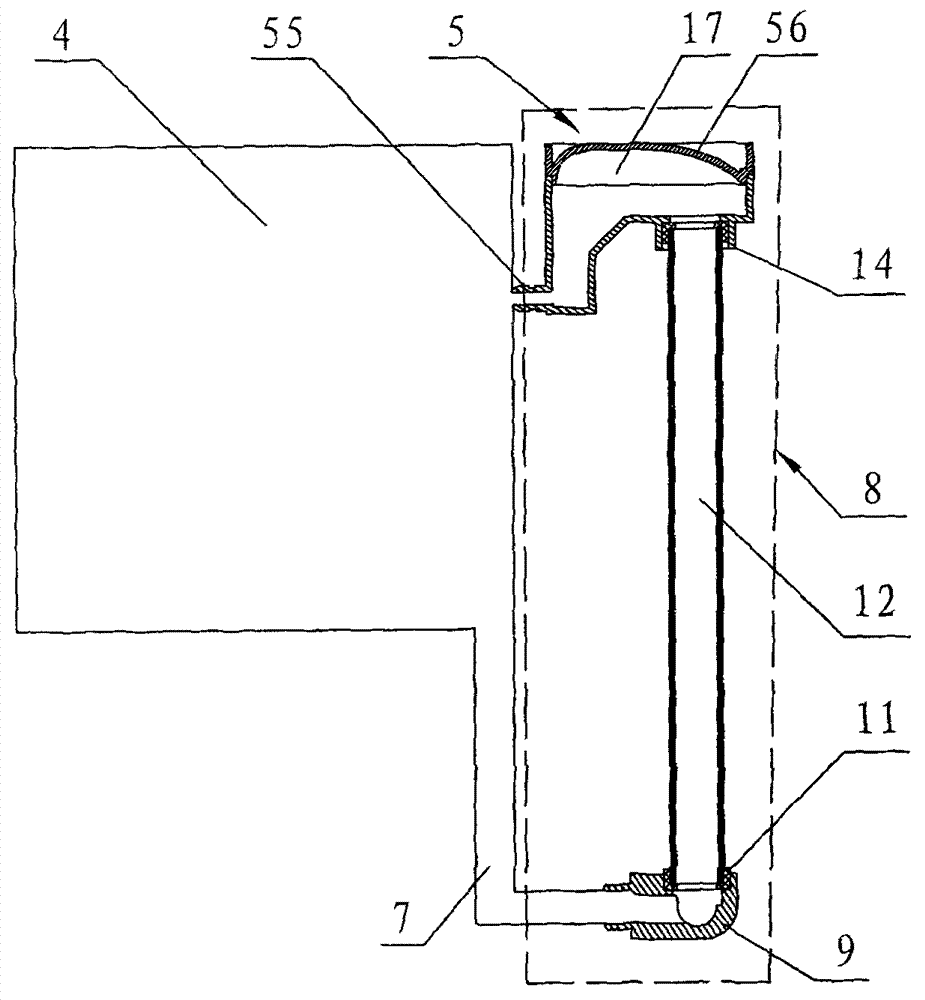

[0031] Such as Figure 4 As shown, the steam-water separator 5 includes a sealing cover 51 , a base 52 , a steam outlet port 53 , a return connection pipe 55 , and three connection seats 14 , and the sealing cover 51 is closed on the base 52 . The connection seat 14 , the steam outlet port 53 , and the return connection pipe 55 are integrally injection molded together with the base 52 . The steam outlet port 53 is arranged on a side wall of the base 52 , and the location of the steam outlet port 53 is 1 mm higher than the bottom surface of the base 52 . The three connecting seats 14 are all arranged on the bottom surface of the base 52 , and the steam outlet port 53 and the connecting seats 14 are all arranged on the same side of the steam-water separator 5 . (Note: 1. The above structures can also be injection molded separately, and then assembled and combined to obtain the base 52; 2. Under the reminder of the prior art, the installation positions of the above structures ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com