Miniature multifunctional motor driving controller

A motor drive and motor control technology, applied in motor control, control systems, electrical components, etc., can solve the problems of increasing system cost, complexity, and large volume, and achieve the effect of simple structure, small volume, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

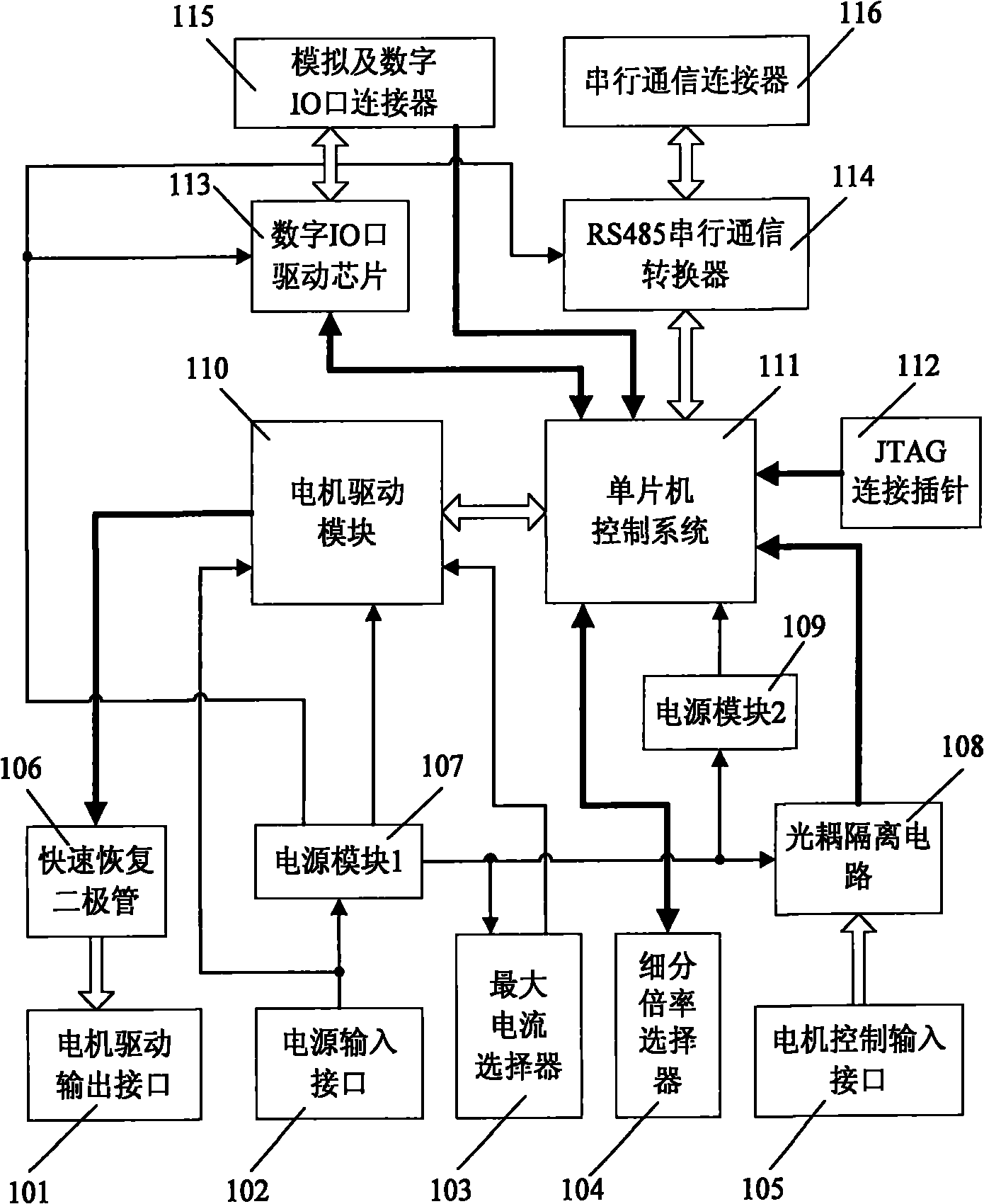

[0022] exist figure 1 Among them, the power input interface 102 is connected to an external power supply to provide input power for the entire system, and the input voltage range is 15 to 40V; the power supply module 107 adopts a wide voltage input, high-efficiency DC-DC module MC34063A, and its output 5V voltage provides For the digital IO port drive chip 113, the motor drive module 110, the maximum current selector 103, the optocoupler isolation circuit 108, and the power module 2 is 109; The 3.3V voltage of the single chip microcomputer control system 111 provides power; pin, compatible with TTL level; optocoupler isolation circuit 108 adopts HCPL-2531; JTAG connection pin 115 is common double-row pin; RS485 serial communication converter 114 adopts SN65HVD485 chip produced by TI Company; serial communication connector 116 Common DB9 connector is adopted; the digital IO port driver chip 113 is composed of two pieces of 74LS245, one of which is the input port driver chip, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com