Buffer

A buffer and buffer column technology, applied in springs/shock absorbers, mechanical equipment, transportation and packaging, etc., can solve the problems of high manufacturing cost and high rigidity index, achieve long service life, reduce rigid connection index and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

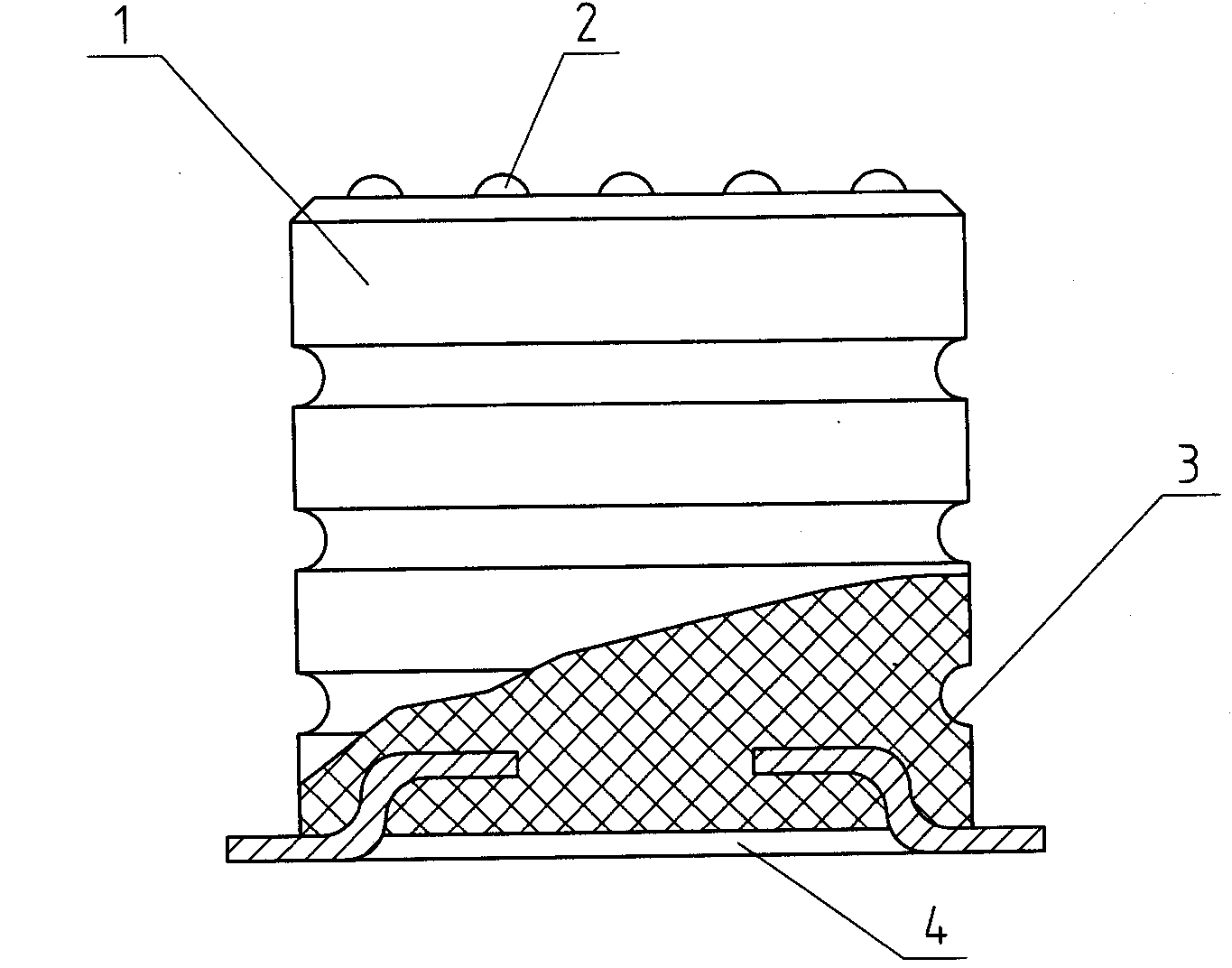

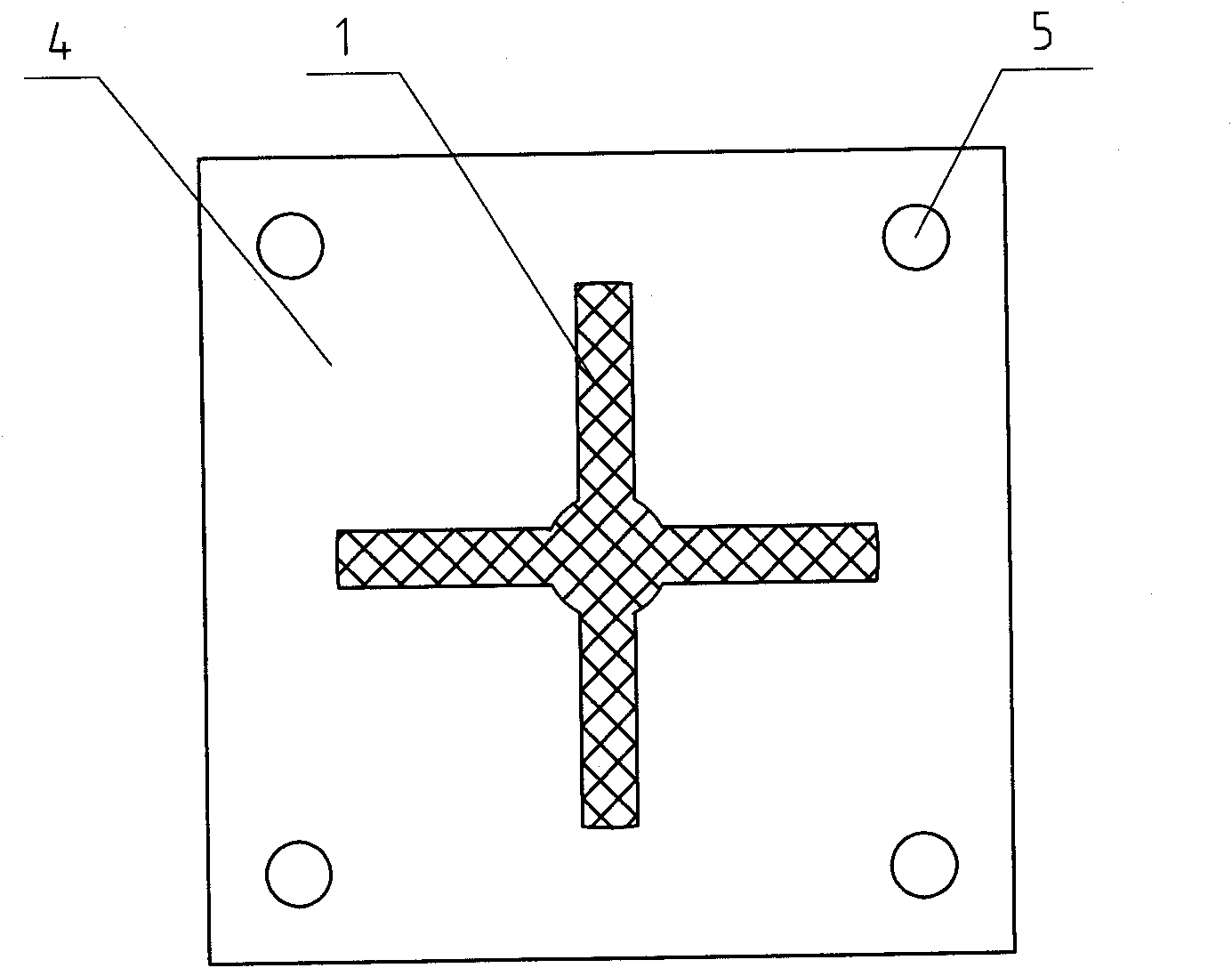

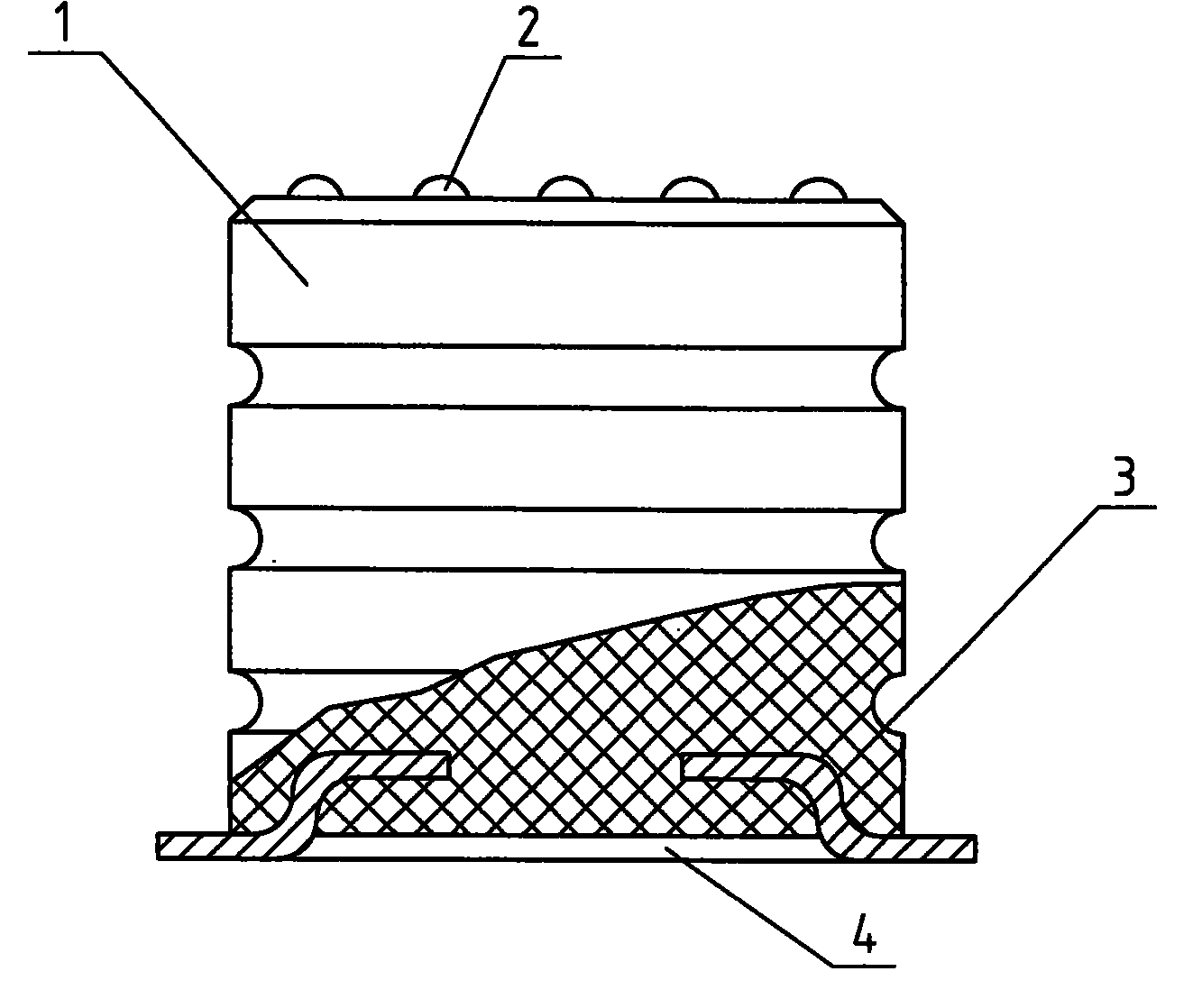

[0012] Such as Figure 1-2 As shown, the main structure of the present invention includes four square mounting base plates 4 with bolt mounting holes 5, the square mounting base plates 4 are fixed on the crane beam or the elevator base by bolts, and four warping plates are stamped on the square mounting base plate 4. The connecting frame 3 is connected to the square mounting base plate 4 with the polyurethane buffer column 1 connected to the connecting frame 3, and the connecting frame 3 is inserted into the polyurethane buffer column 1. In order to increase the density of the polyurethane buffer cylinder and improve its buffer effect, the polyurethane molecular weight of the polyurethane buffer cylinder is 300-6000. In order to increase the frictional force, anti-slip protrusions 2 are arranged on the top of the polyurethane buffer cylinder.

[0013] When working, the top of the polyurethane buffer cylinder 1 is the impact bearing surface. After receiving the impact force, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com