Swirling electronic-controlled fuel injector of gasoline engine

An electronically controlled fuel injection and swirling technology, which is applied to machines/engines, mechanical equipment, engine components, etc., can solve the problems of high anti-clogging performance, deterioration of engine performance, and harsh operating environment, and achieves strong creativity and practicability. , Improve the anti-clogging ability, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

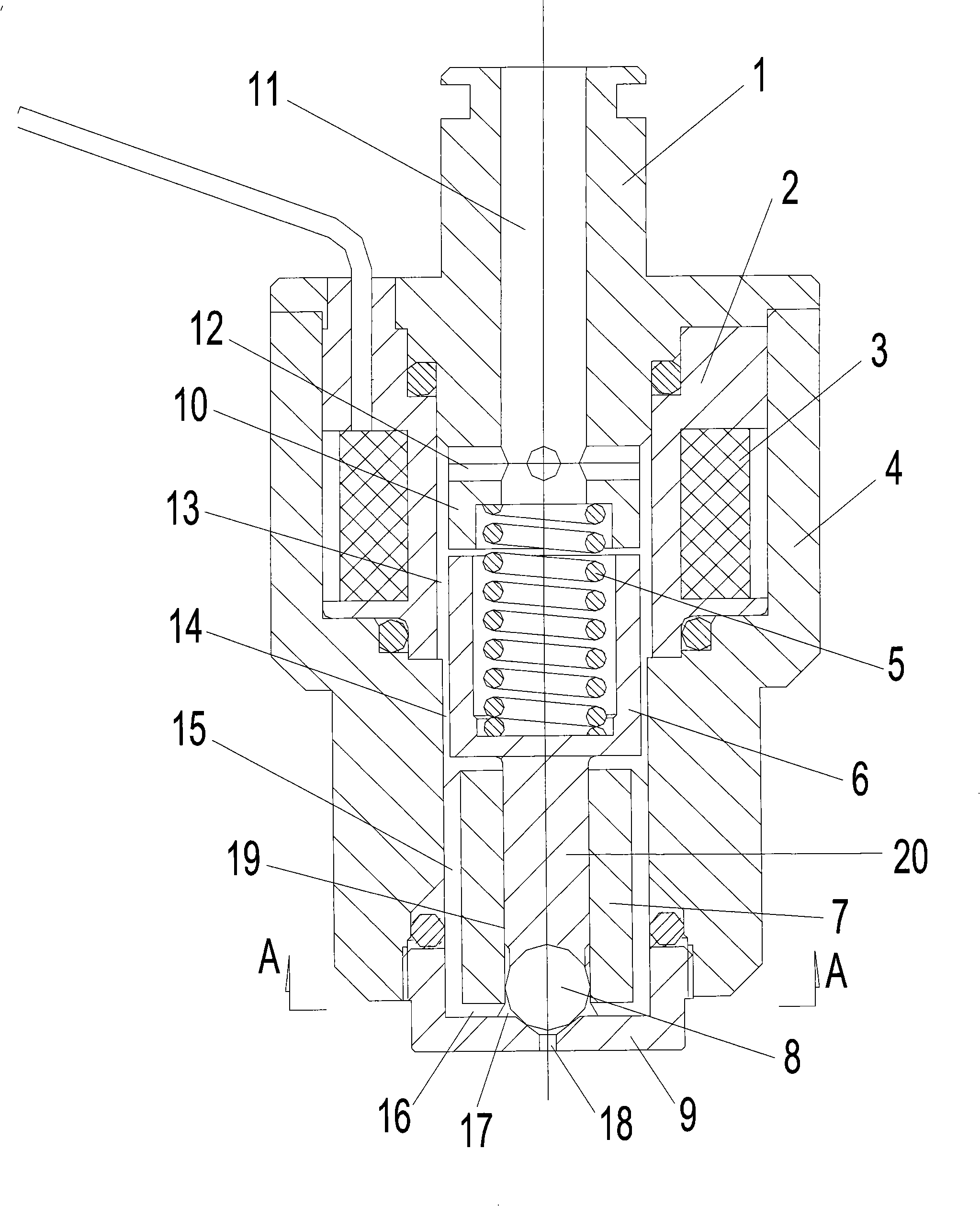

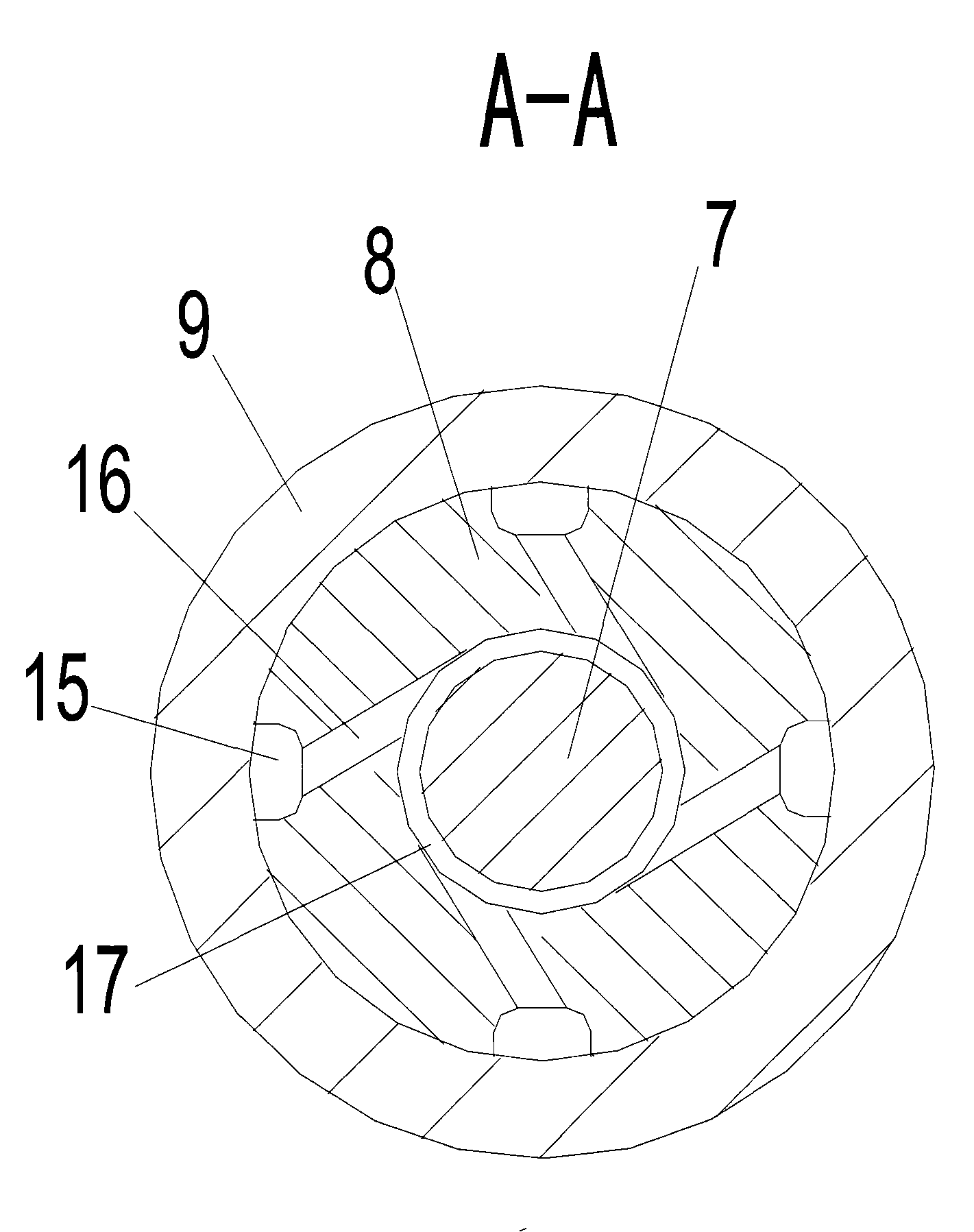

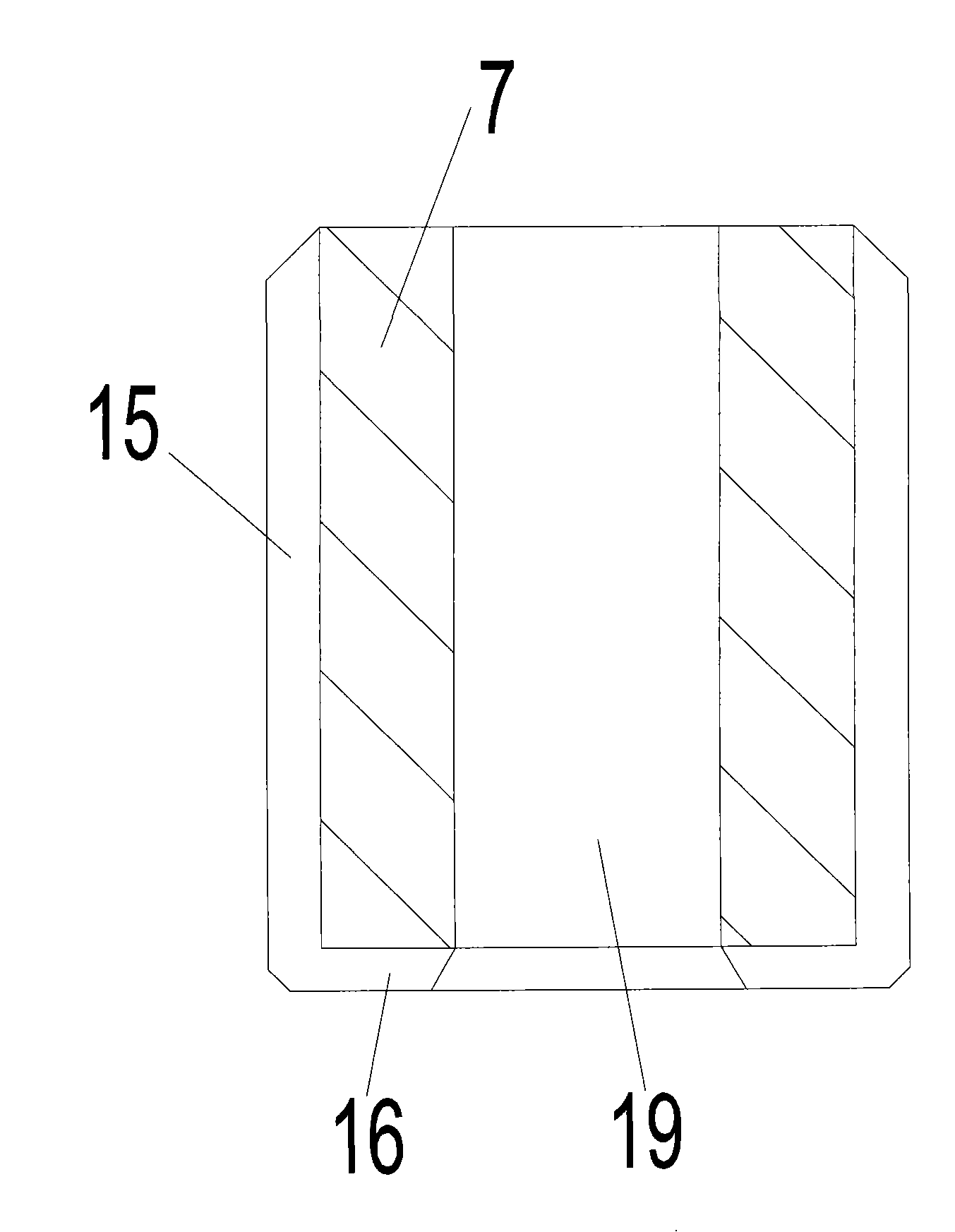

[0044] The first kind of embodiment: set up the oil passage groove 15 on the outer surface of the guide sleeve 7, and set up the diversion groove 16 on the bottom surface of the guide sleeve 7, such as Figure 1-4 shown.

[0045] The second implementation mode: open an oil passage groove 15 on the outer surface of the guide sleeve 7, and set up a diversion groove 16 on the valve seat 9, such as Figure 5 , 6 shown.

[0046] Third embodiment: between the guide sleeve 7 , the housing 4 and the valve seat 9 , a hollow sheet structure with an oil groove 15 and a diversion groove 16 is clamped and installed.

[0047] Above-mentioned three kinds of structure embodiments, its oil passage groove 15 is connected with flow guide groove 16, and flow guide groove 16 is connected with vortex chamber 17 with the direction tangential to vortex chamber 17, and the quantity of oil passage groove 15, flow guide groove 16 is different. for four.

[0048] When the coil 3 is energized, the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com