Prestressed cuboid support pile for building foundation pit, manufacturing method thereof and forming die

A technology for forming molds and prestressing, which is used in molds, construction, manufacturing tools, etc., can solve the problems that the role of steel bars cannot be fully exerted, the steel cages cannot be prestressed, and the overall cost of construction projects is increased. The effect of construction cost, lateral bending moment increase and construction period shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

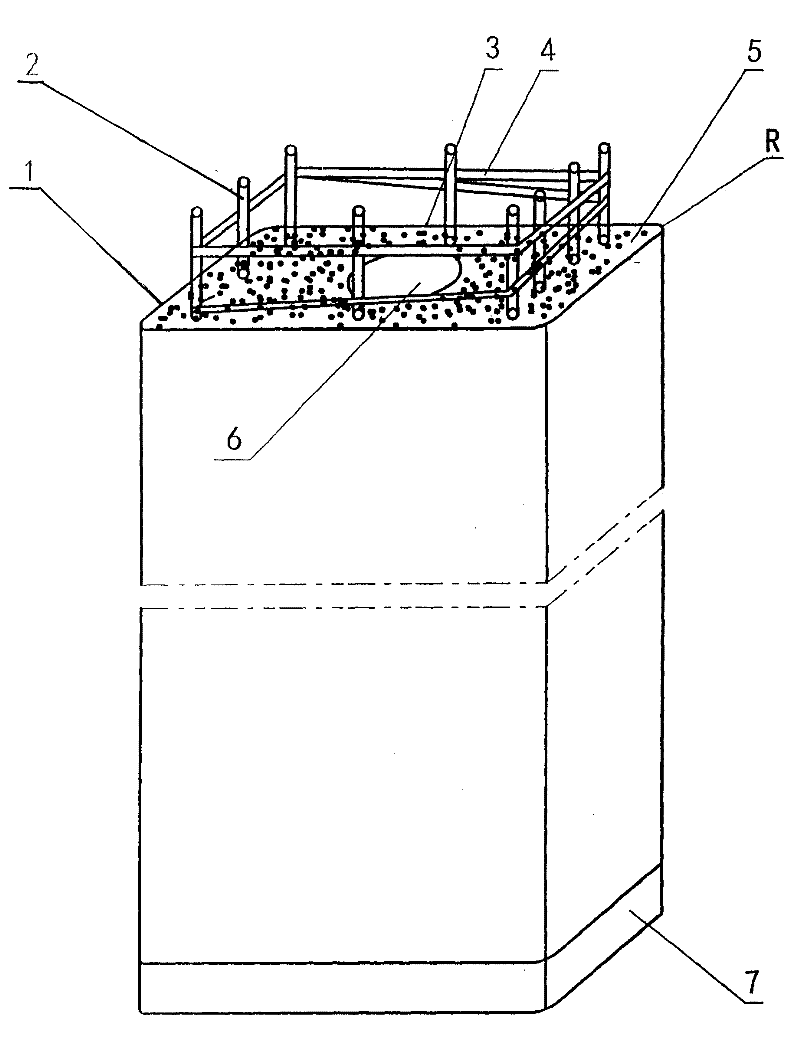

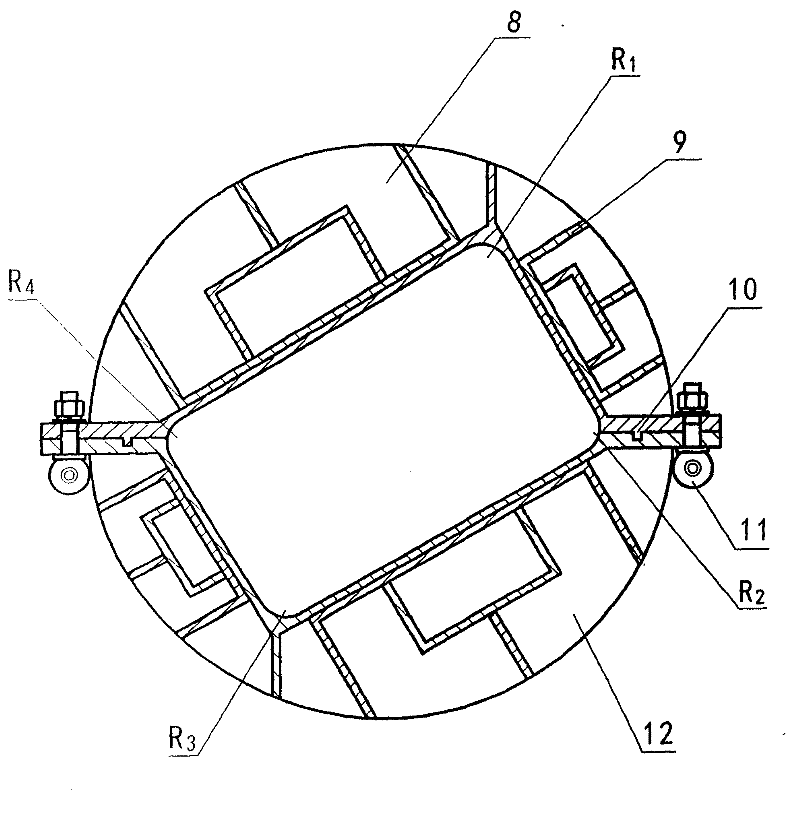

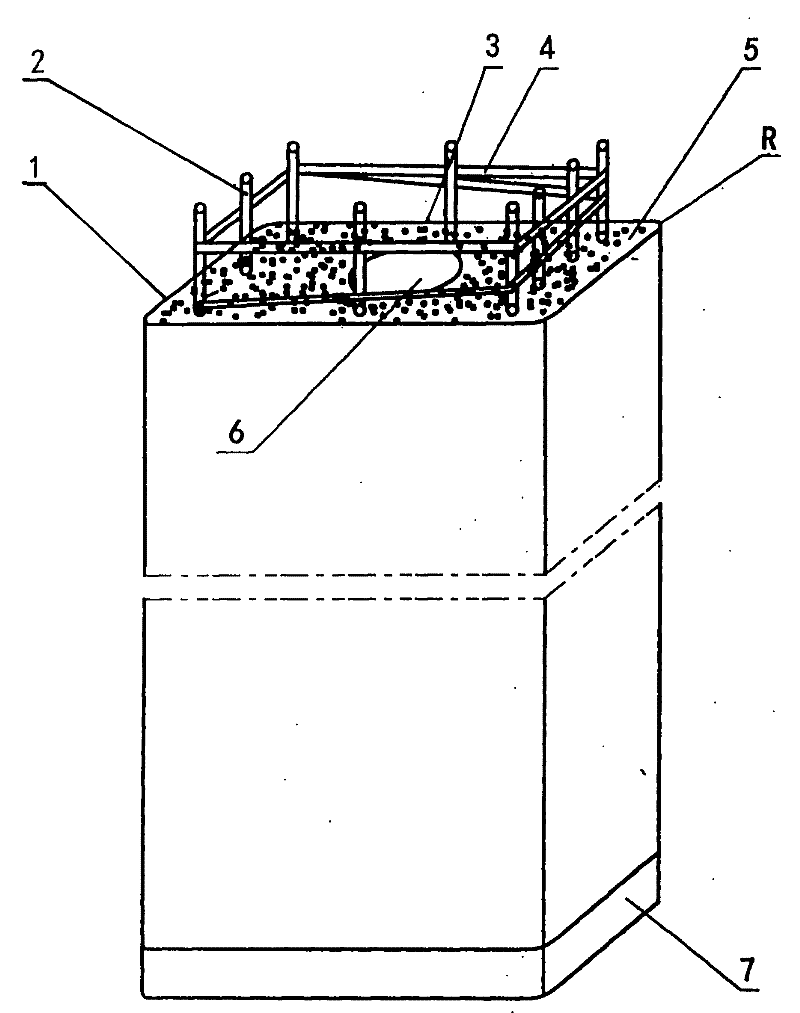

[0018] Prestressed rectangular parallelepiped support piles for building foundation pits, including reinforcement cages and concrete 5, metal end plates 7 connected to the reinforcement cages at both ends of the pile body, circular through holes 6 in the center of the pile body, and stirrup bars 4 of the reinforcement cage in the form of Helically welded on the longitudinal reinforcement 2, the longitudinal reinforcement 2 is prestressed, so that the strength of the pile body is high, the cross section of the pile body is rectangular, and the ratio of the short side 1 to the long side 3 of the cross section of the pile body is 2:3. According to the stress characteristics of the support pile, the arrangement of the longitudinal reinforcement 2 in the support pile is optimized, the number of longitudinal reinforcement 2 is reduced, and the support on the side of the short side 1 of the cross-section of the pile body that bears the tensile force 4 longitudinal ribs 2 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com