Top coating for coating layer of double-sided coating white board as well as preparation method and application thereof

A technology of double-sided coating and white board paper, which is applied in the direction of paper coating, coating, paper, etc., can solve the problems of high cardboard smoothness, low cardboard stiffness, wood waste, etc., achieve obvious visual effects, improve hue, improve grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

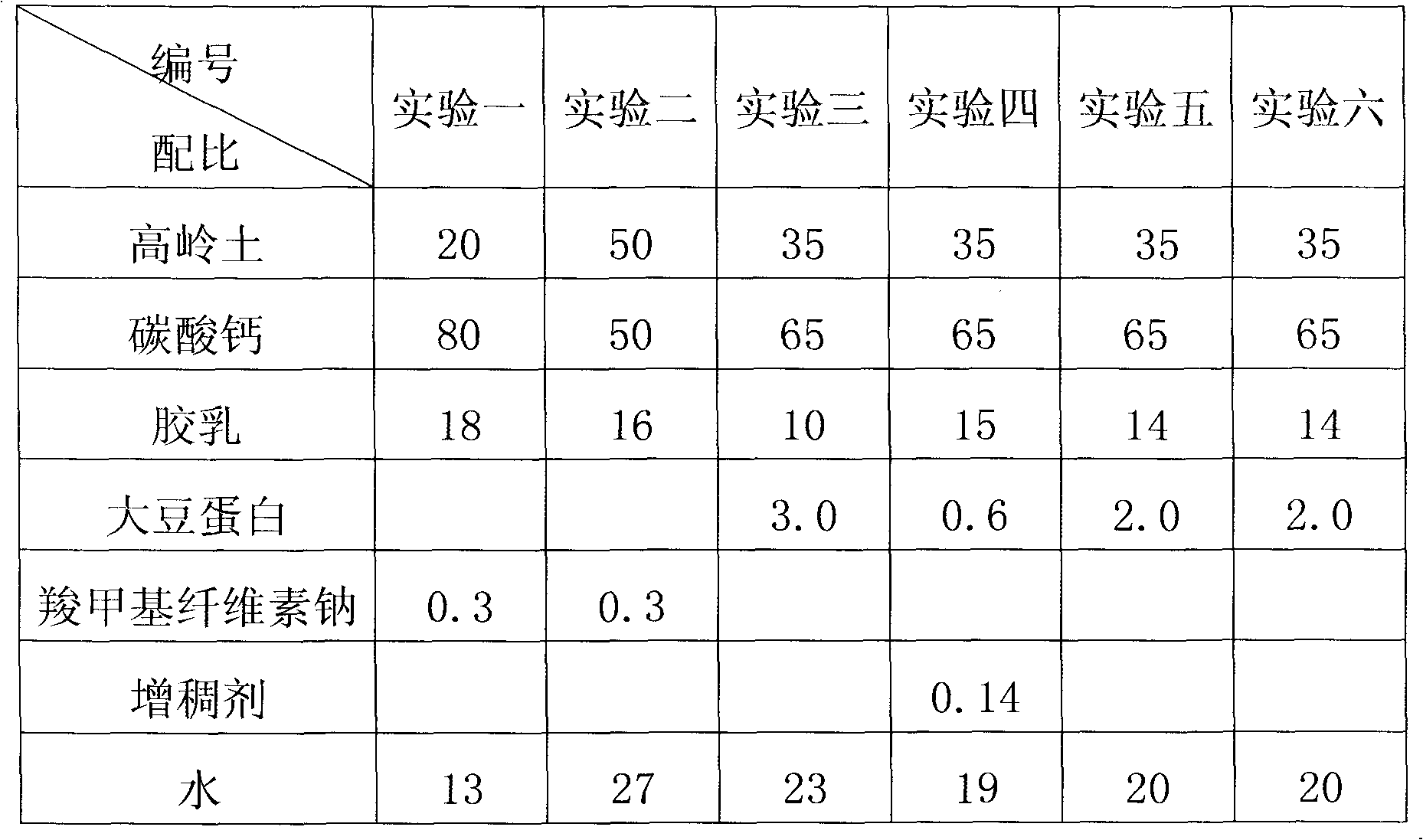

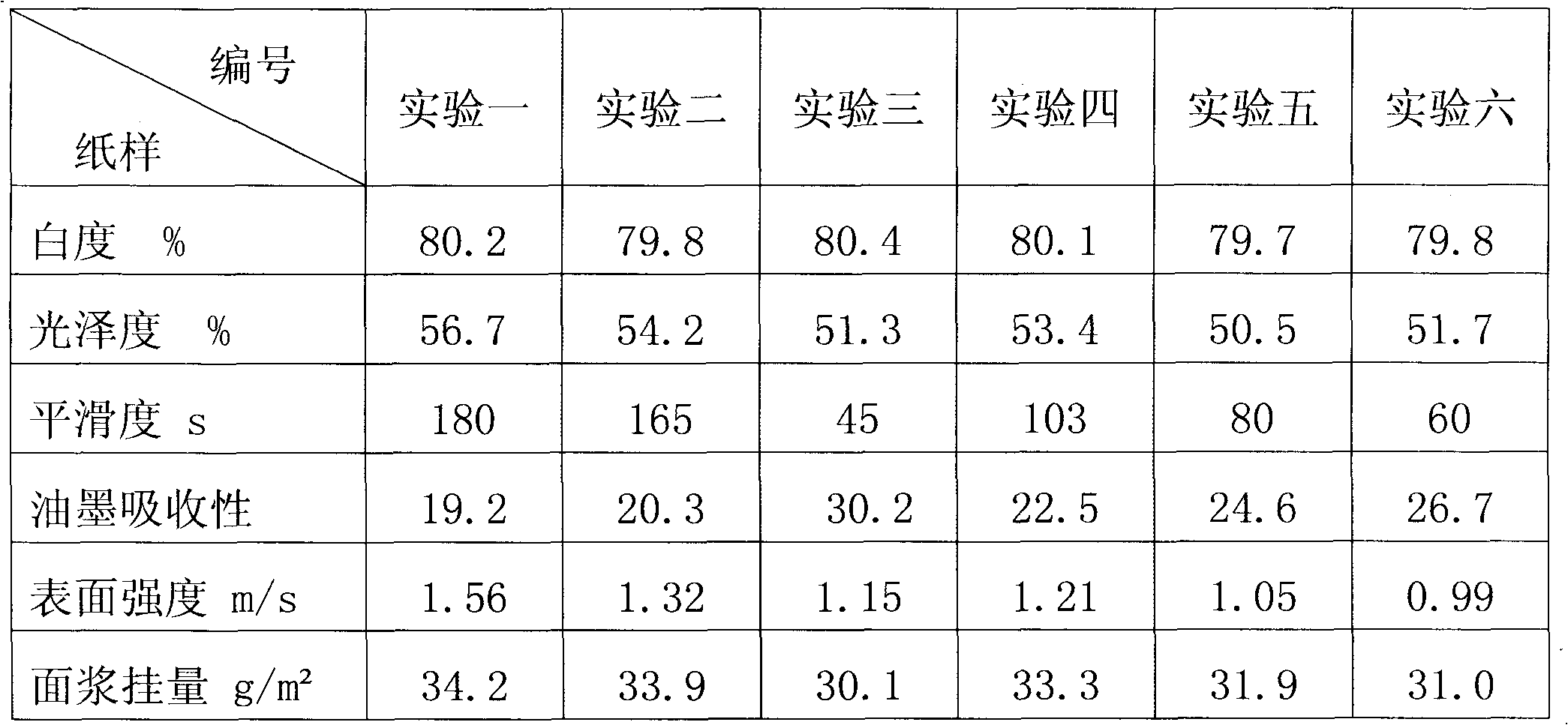

[0040] Embodiment 1~6 (wherein the type of experiment five and experiment six latex is different)

[0041] Coating Formulation

[0042]

[0043] Among them: the latex in Experiment 1 to Experiment 5 had a glass transition temperature less than 10°C, and the latex in Experiment 6 had a glass transition temperature greater than 10°C; in Experiment 4, a thickener was used to adjust the viscosity of the coating due to the small amount of soybean protein used; Additives have been added.

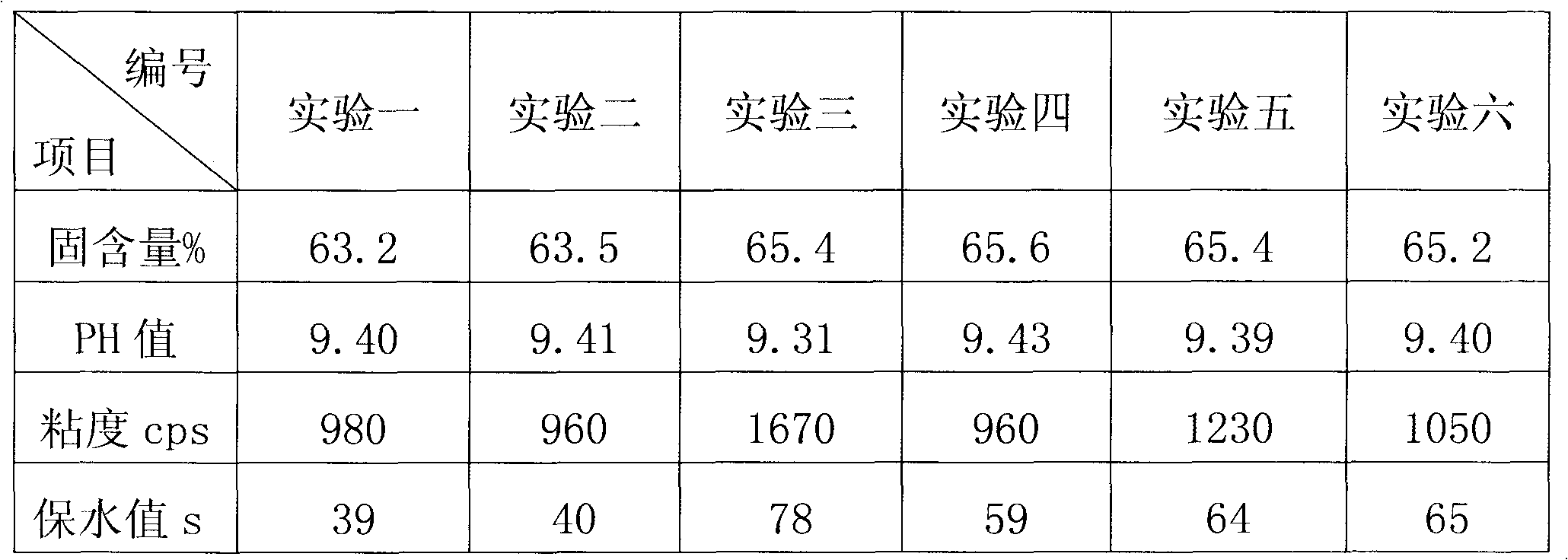

[0044] Coating performance index:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com