Sag resistant polypropylene and preparation method thereof

A polypropylene and linear polypropylene technology, which is applied in the field of polymer material synthesis, can solve the problems of the physical and mechanical properties of fragile materials, the influence of the physical and mechanical properties of polypropylene, and the complex process, and achieves low preparation cost and high anti-sag. The effect of sex, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-20 and comparative example 1-4

[0035] main ingreadient:

[0036] Polypropylene 1 (PP1), F401, Panjin Ethylene Co., Ltd.;

[0037] Polypropylene 2 (PP2), T36F, Qilu Petrochemical Co., Ltd.;

[0038] Organic nanoclay, I.44P, American nanocor company;

[0039] Compatibilizer 1, maleic anhydride grafted polypropylene, Polybond 3200, melt flow rate 110g / 10min (190°C), maleic anhydride grafting rate 1%, U.S. Compton Company;

[0040] Compatibilizer 2, maleic anhydride grafted polypropylene, Fusabond 353D, melt flow rate 450g / 10min (190°C), maleic anhydride grafting rate 1.4%, U.S. DuPont;

[0041] Compatibilizer 3, maleic anhydride grafted polypropylene, Fusabond 511D, maleic anhydride grafting rate 0.5%, U.S. DuPont (the grafting rate of three kinds of compatibilizers is all provided by product supplier);

[0042] Antioxidant, IRGANOX1010, Ciba Specialty Chemicals;

[0043] White oil, chemically pure, Tianjin Huiying Chemical Reagent Co., Ltd.;

[0044] The composition of the anti-sag polypropylene provided...

Embodiment 9

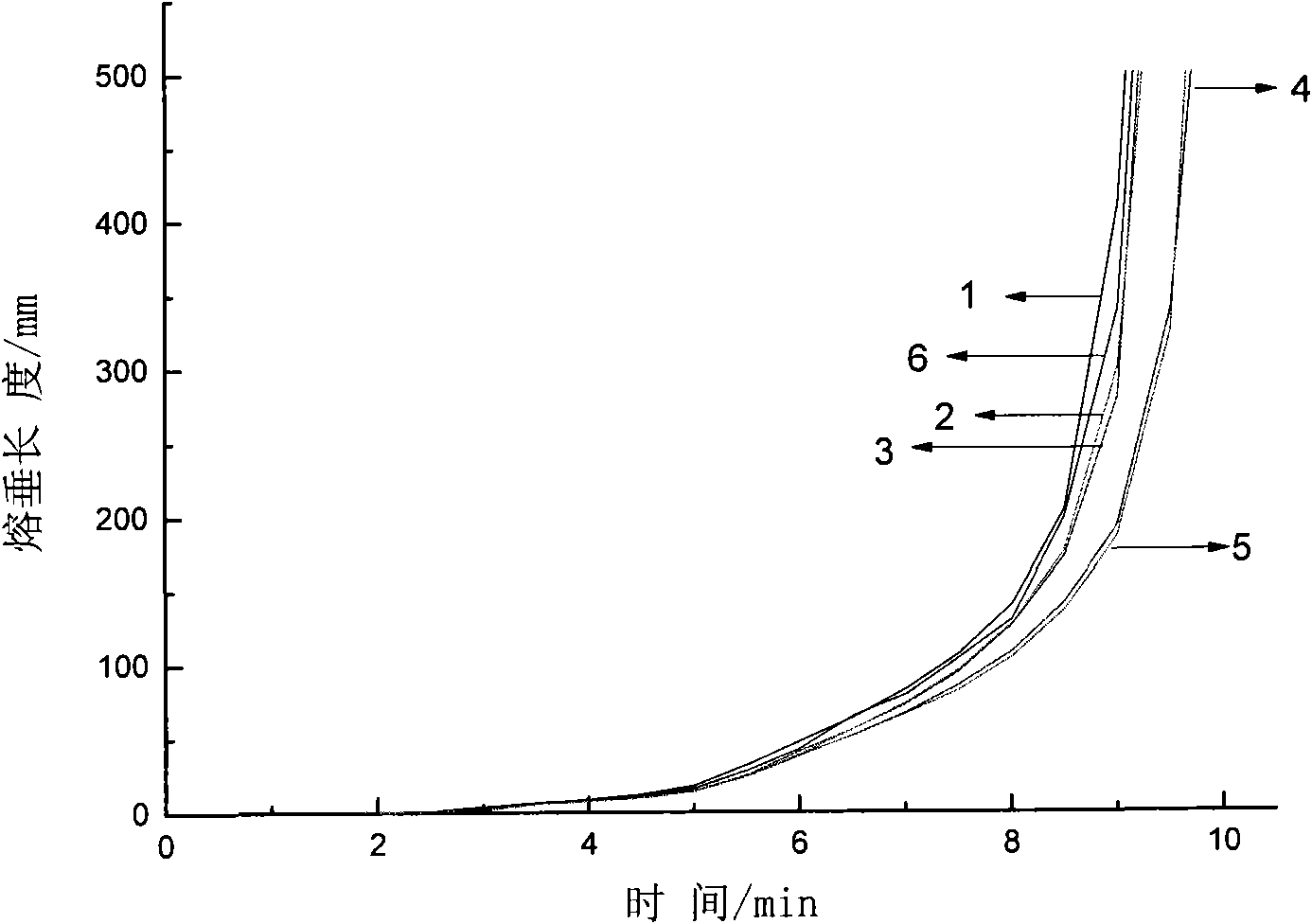

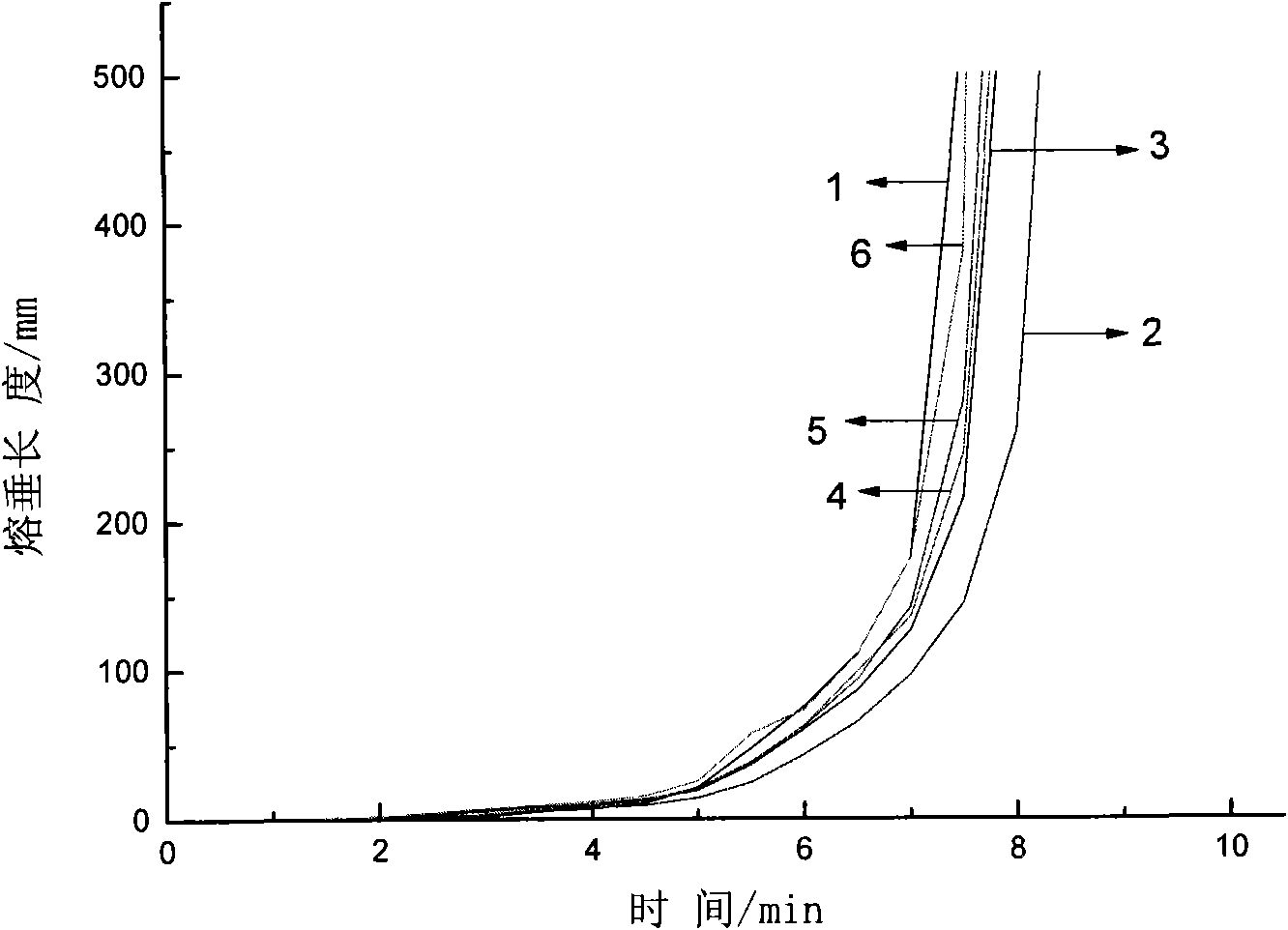

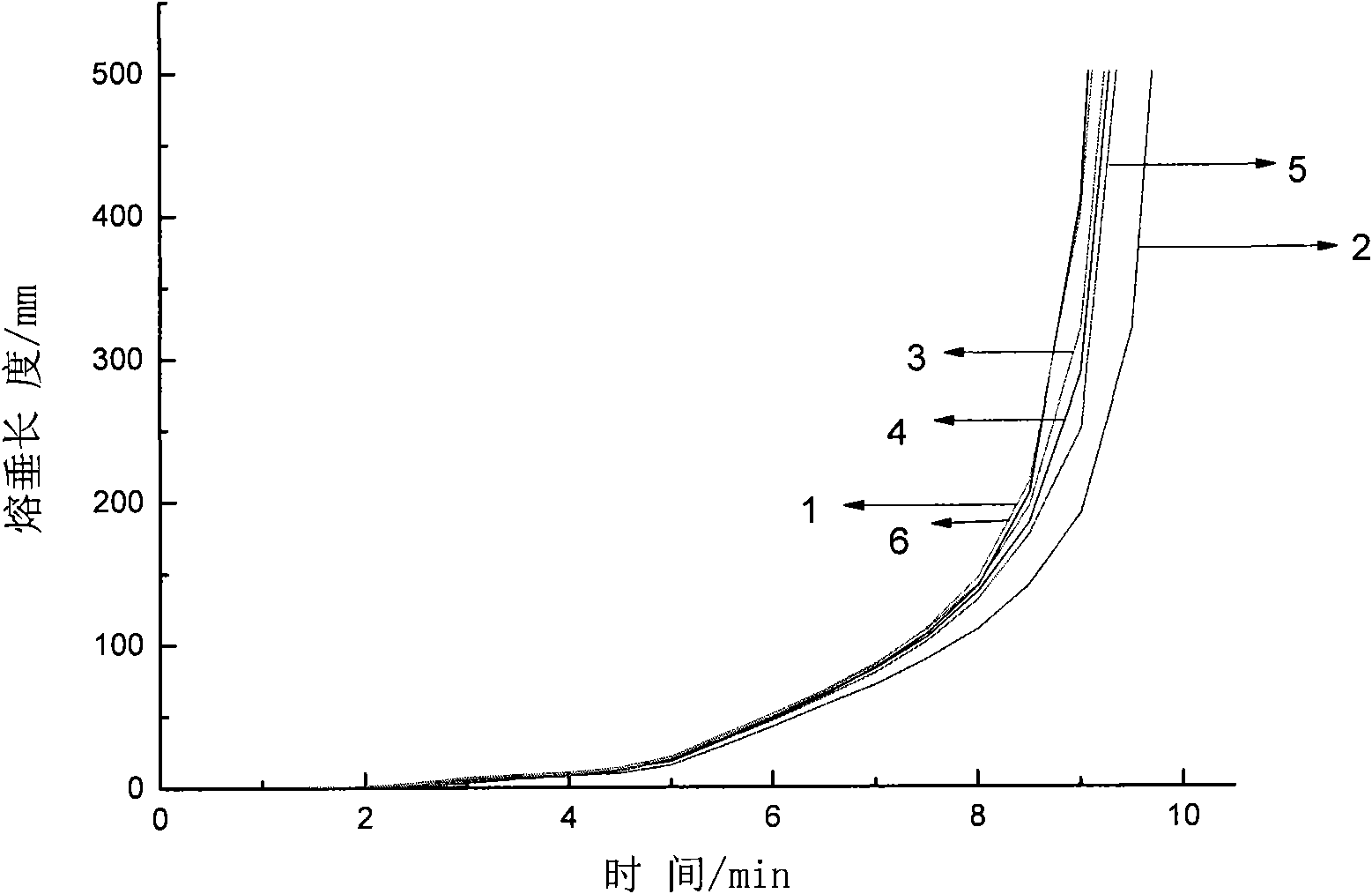

[0057] In Examples 9-16 and Comparative Examples 3-4, different contents of compatibilizer Fusabond 353D were added to polypropylene F401 and T36F, and the anti-sag properties of the prepared anti-sag polypropylene were as follows: image 3 and Figure 4 As shown, among them, image 3 Curve 1 in the graph represents polypropylene F401, curves 2-5 represent the sag-resistant polypropylene prepared in Examples 9-12, and curve 6 represents the sag-resistant polypropylene prepared in Comparative Example 3; Figure 4 Curve 1 in the graph represents polypropylene T36F, curves 2-5 represent the sag-resistant polypropylene prepared in Examples 13-16, respectively, and curve 6 represents the sag-resistant polypropylene prepared in Comparative Example 4. From image 3 and Figure 4 It can be seen that the anti-sag performance of the anti-sag polypropylene prepared by adding compatibilizer Fusabond 353D is greatly improved compared with that of the polypropylene matrix F401 and T36F. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com