Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

A manufacturing method and technology of sports shoes, applied in the field of sports shoes soles, can solve the problems of no anti-slip performance, short life, high density, etc., and achieve the effect of low cost, low density and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of injection imitation PU foaming sports shoe sole mainly comprises the following steps:

[0029] 1) Pound material

[0030] Weigh the raw materials according to the designed formula, bag the bridging agent and high-temperature foaming agent separately, and mix other materials together.

[0031] 2) Banbury

[0032] Pour the prepared raw materials except DCP and AC-6000H into a 75-liter internal mixer, and start the internal mixer to mix the materials evenly. The mixing time of the first stage is 7-8 minutes, and the number of material turning is 4-5 times. When the temperature reaches 110°C-112°C, add DCP and AC-6000H, and start the mixer again. The banburying time of the second stage is 2-3 minutes, and the number of times of material turning is 2-3 times. When the temperature continues to rise to 115°C-118°C, all raw materials have been mixed evenly, and the materials are poured out for kneading.

[0033] 3) open refining

[0034] Thinning ...

Embodiment 1

[0048] Embodiment 1: It is an experimental formula designed according to the traditional way of thinking, and its dosage is a research and development sample, measured in grams.

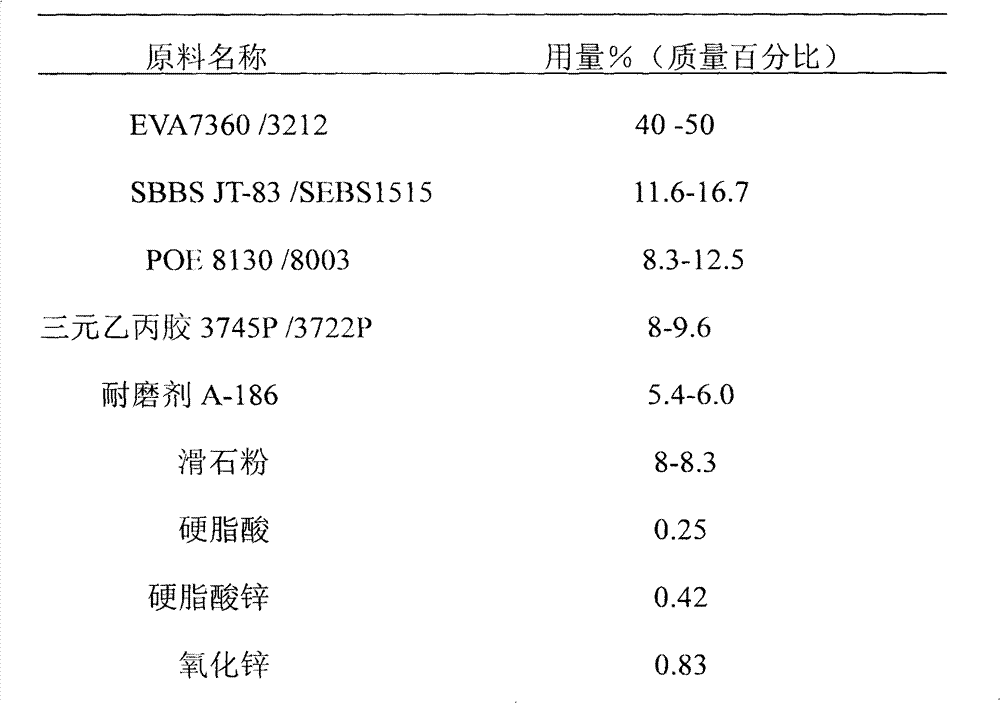

[0049] Table 2

[0050]

[0051]

Embodiment 2

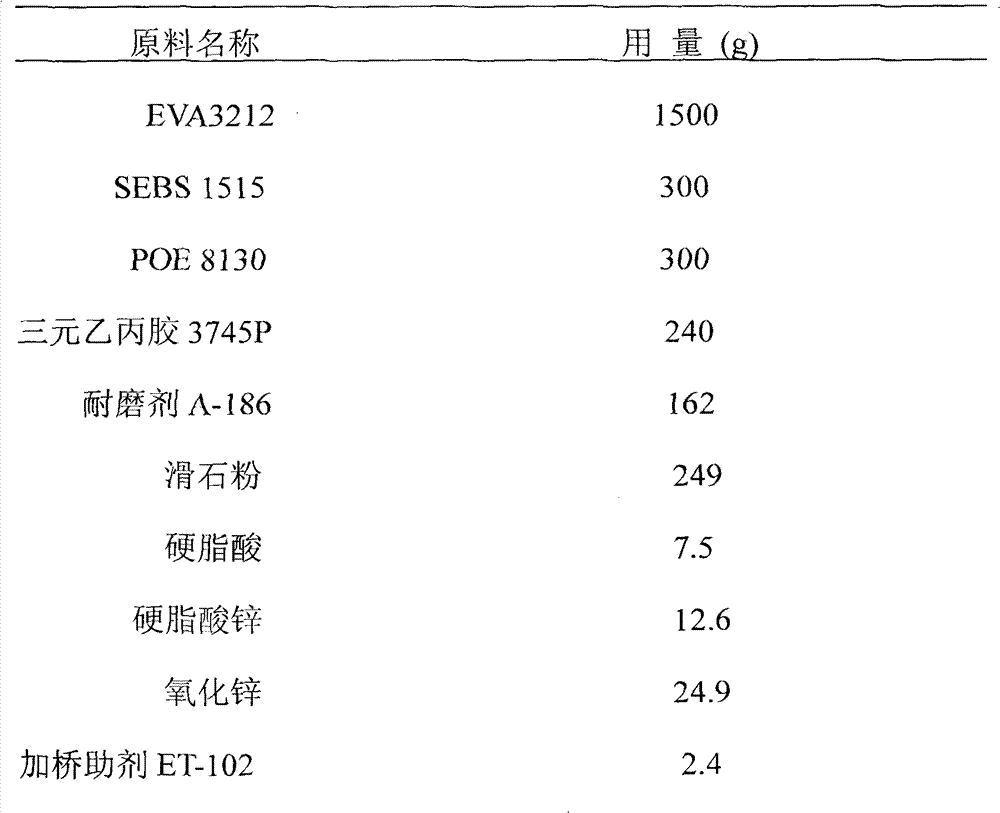

[0052] Embodiment 2: Similar to Embodiment 1, the difference is that the raw material formula is shown in Table 3.

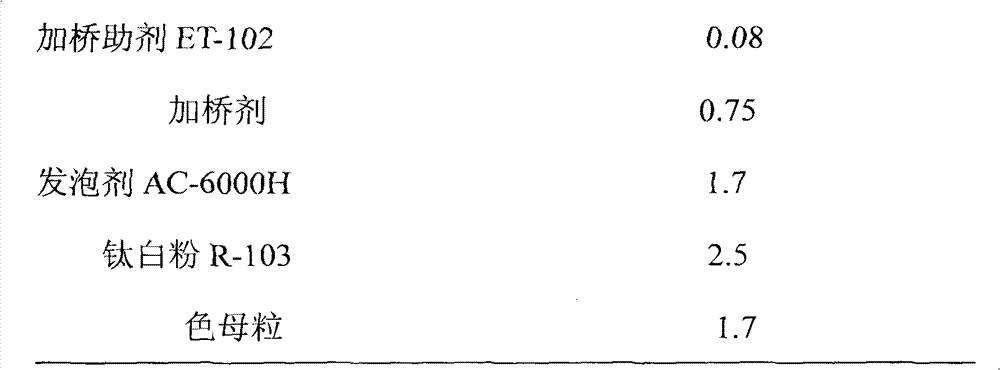

[0053] table 3

[0054]

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com