Sludge treatment method

A technology for sludge and sludge granules, applied in pyrolysis treatment of sludge, combustion methods, energy and wastewater treatment, etc., can solve problems such as wasting energy and polluting the environment, and achieve low operating costs, prevention of secondary pollution, and economic benefits. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

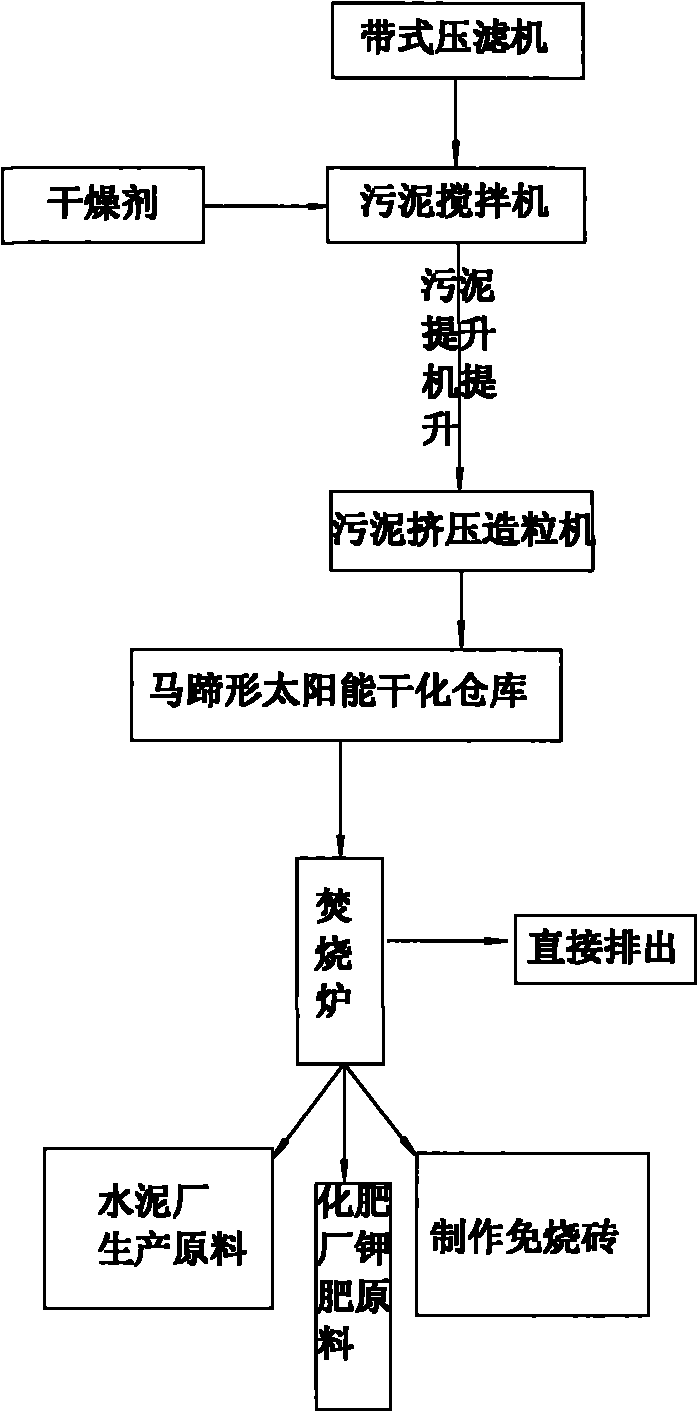

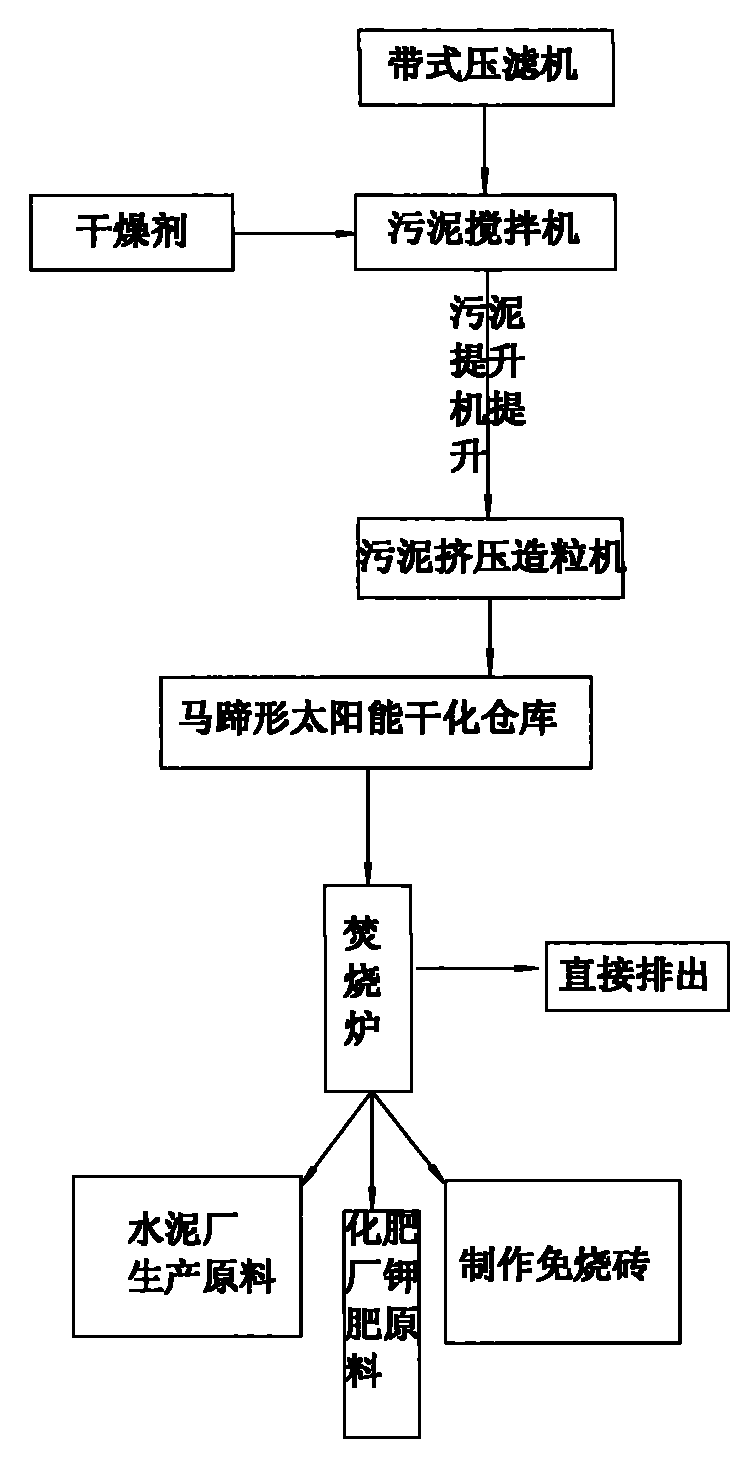

Method used

Image

Examples

Embodiment 1

[0023] 100kg of sludge with a moisture content of 75% is transported to the sludge mixer, and 30kg of desiccant is added. The weight ratio of the desiccant is 17kg of straw, 13kg of quicklime, and stirred for 1.5 hours. The sludge undergoes a chemical reaction and is granulated by sludge extrusion. Squeeze and dry by machine to form long cylindrical sludge particles with a diameter of 32mm, a length of 45mm, and a moisture content of 57%. The sludge particles are transported to the solar drying warehouse and dried at a temperature of 40°C Deodorization and disinfection; when the moisture content of the sludge particles drops to 20%, send them to the incinerator for full combustion, the temperature can reach 750°C, and discharge the residual waste residue after combustion; or use the residual waste residue as the raw material for cement plant production ; or directly made into unburned bricks; or used as potash fertilizer raw material for fertilizer plants.

Embodiment 2

[0025] 100kg of sludge with a water content of 80% is transported to the sludge mixer, and 25kg of desiccant is added. The weight ratio of the desiccant is 15kg of straw, 10kg of quicklime, and stirred for 1 hour. The sludge undergoes a chemical reaction and is granulated by sludge extrusion. Squeeze and dry by machine to form long cylindrical sludge particles with a diameter of 30mm, a length of 40mm, and a moisture content of 58%. The sludge particles are transported to the solar drying warehouse and dried at a temperature of 60°C Deodorization and disinfection; when the moisture content of the sludge particles drops to 25%, send them to the incinerator for full combustion, the temperature can reach 720°C, and discharge the residual waste residue after combustion; or use the residual waste residue as the raw material for cement plant production ; or directly made into unburned bricks; or used as potash fertilizer raw material for fertilizer plants.

Embodiment 3

[0027] 100kg of sludge with a moisture content of 82% is transported to the sludge mixer, and 10kg of desiccant is added. The weight ratio of the desiccant is 8kg of straw, 2kg of quicklime, and stirred for 2 hours. The sludge undergoes a chemical reaction and is granulated by sludge extrusion. Squeeze and dry by machine to form long cylindrical sludge particles with a diameter of 35mm, a length of 55mm, and a moisture content of 60%. The sludge particles are transported to the solar drying warehouse and dried at a temperature of 80°C Deodorization and disinfection; when the moisture content of the sludge particles drops to 30%, send them to the incinerator for full combustion, the temperature can reach 500°C, and discharge the residual waste residue after combustion; or use the residual waste residue as the raw material for cement plant production ; or directly made into unburned bricks; or used as potash fertilizer raw material for fertilizer plants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com