Method for extracting natural tea polyphenol

A tea polyphenol and natural technology, applied in the field of tea polyphenol extraction, can solve the problems of porogen synthesis raw materials and solvent residues and high cost, and achieve the effects of low caffeine content, low usage amount and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

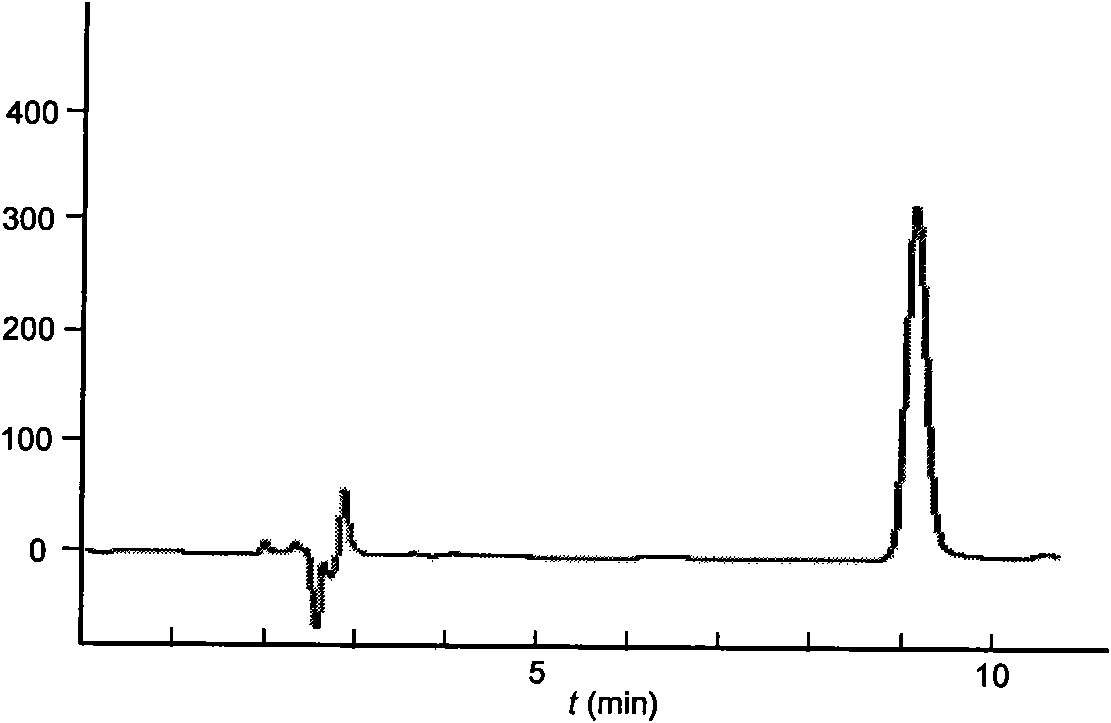

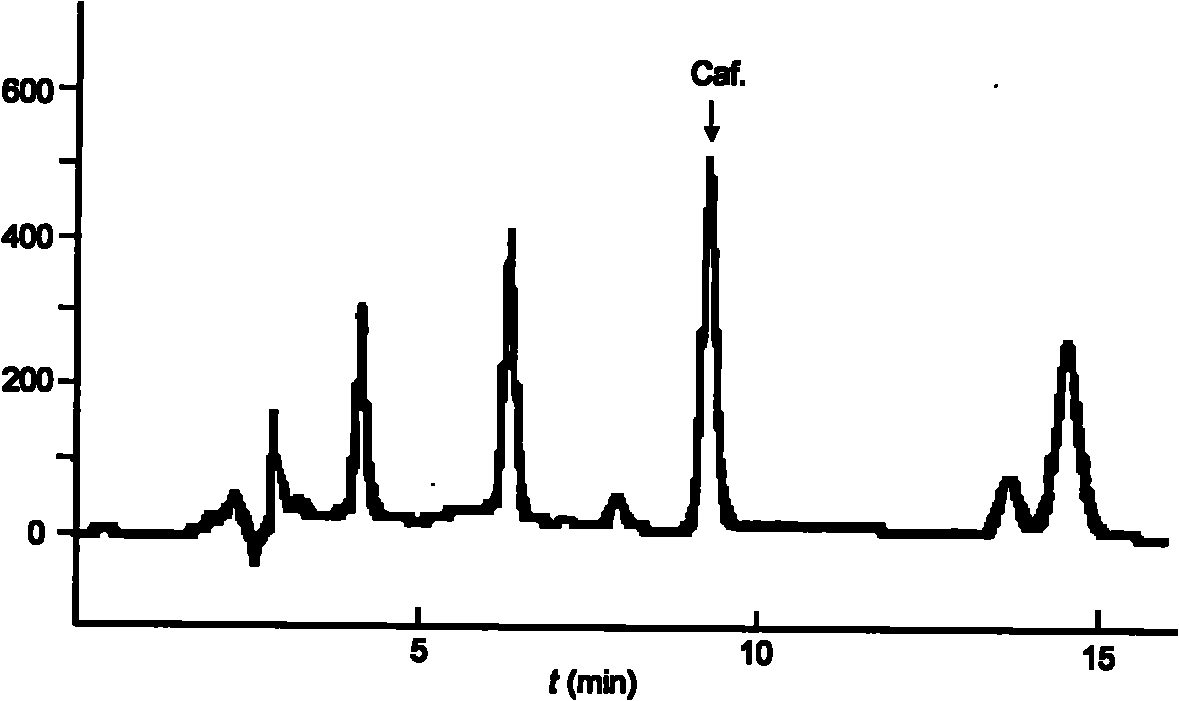

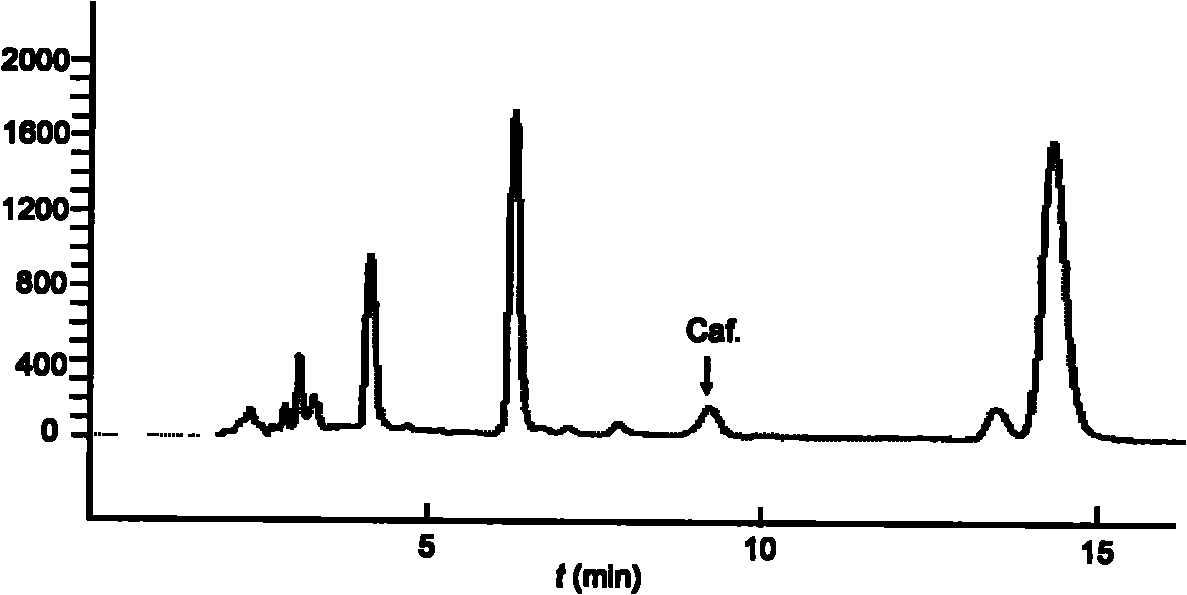

Image

Examples

Embodiment 1

[0025] Use commercially available FAU zeolite powder with a silicon-aluminum ratio of 72, process it into strips (diameter 2.5mm), cut into short strips of 3-5mm after high-temperature roasting, activate in air at 550°C for 4 hours and cool, then place in After deionized water is properly heated to fully remove air bubbles, add it to the adsorption column. The adsorption column has a height of 45cm, an inner diameter of 3cm, and a zeolite adsorbent loading capacity of 120g.

[0026] Weigh 5 grams of instant tea powder, prepare 0.01 g / mL tea, and filter to remove insoluble impurities. Adjust the flow rate to be stable at 5.5mL / min, pump 500mL tea water solution containing tea polyphenols to the adsorption column with a constant flow pump, and immediately pump 20-500mL deionized water after the tea water solution is exhausted. Then eluted with 200-2000ml of 7% ethanol solution, collected the ethanol eluate, concentrated by ultrafiltration, added a small amount of absolute ethan...

Embodiment 2

[0028] Use commercially available FAU zeolite powder with a silicon-aluminum ratio of 60, process it into strips (diameter 2.5mm), cut into short strips of 3-5mm after high-temperature roasting, activate in air at 500°C for 4 hours and cool, then place in After deionized water is properly heated to fully remove air bubbles, add it to the adsorption column. The adsorption column has a height of 45cm, an inner diameter of 3cm, and a zeolite adsorbent loading capacity of 125g.

[0029] Weigh 10 grams of instant tea powder, prepare 0.01 g / mL tea, and filter to remove insoluble impurities. Adjust the flow rate to be stable at 8mL / min, pump 1L tea solution containing tea polyphenols to the adsorption column with a constant flow pump, and immediately pump 30-1000mL deionized water after the tea solution is exhausted. Then eluted with 200-2000mL 20% ethanol solution, collected the ethanol eluate, concentrated by ultrafiltration, added a small amount of absolute ethanol and rotary eva...

Embodiment 3

[0031] Use commercially available FAU zeolite powder with a silicon-aluminum ratio of 15, process it into small balls with a particle size of 1.5-2mm, roast at 600°C for 3.5 hours, and perform hydrophobization treatment at 120°C for 2 hours. Place in deionized water, heat properly to fully remove air bubbles, and then add to the adsorption column. The adsorption column has a height of 45cm, an inner diameter of 3cm, and a loading capacity of 126g of zeolite adsorbent.

[0032] Weigh 5 grams of instant tea powder, prepare 0.01 g / mL tea, and filter to remove insoluble impurities. Adjust the flow rate to be stable at 10mL / min, pump 500mL of tea water solution containing tea polyphenols to the adsorption column with a constant flow pump, and the adsorption column is kept at a temperature of 50°C through circulating water. After the tea solution is exhausted, immediately pump 20-200mL of deionized water. Subsequently, it was eluted with 200-2000 mL of 10% ethanol solution, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com