One-touch joint for piping

A pipe joint and direct plug-in technology, which is applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc., can solve problems such as falling off and leaking pipe body, and achieve improved water-tightness, firm connection, and easy operation. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

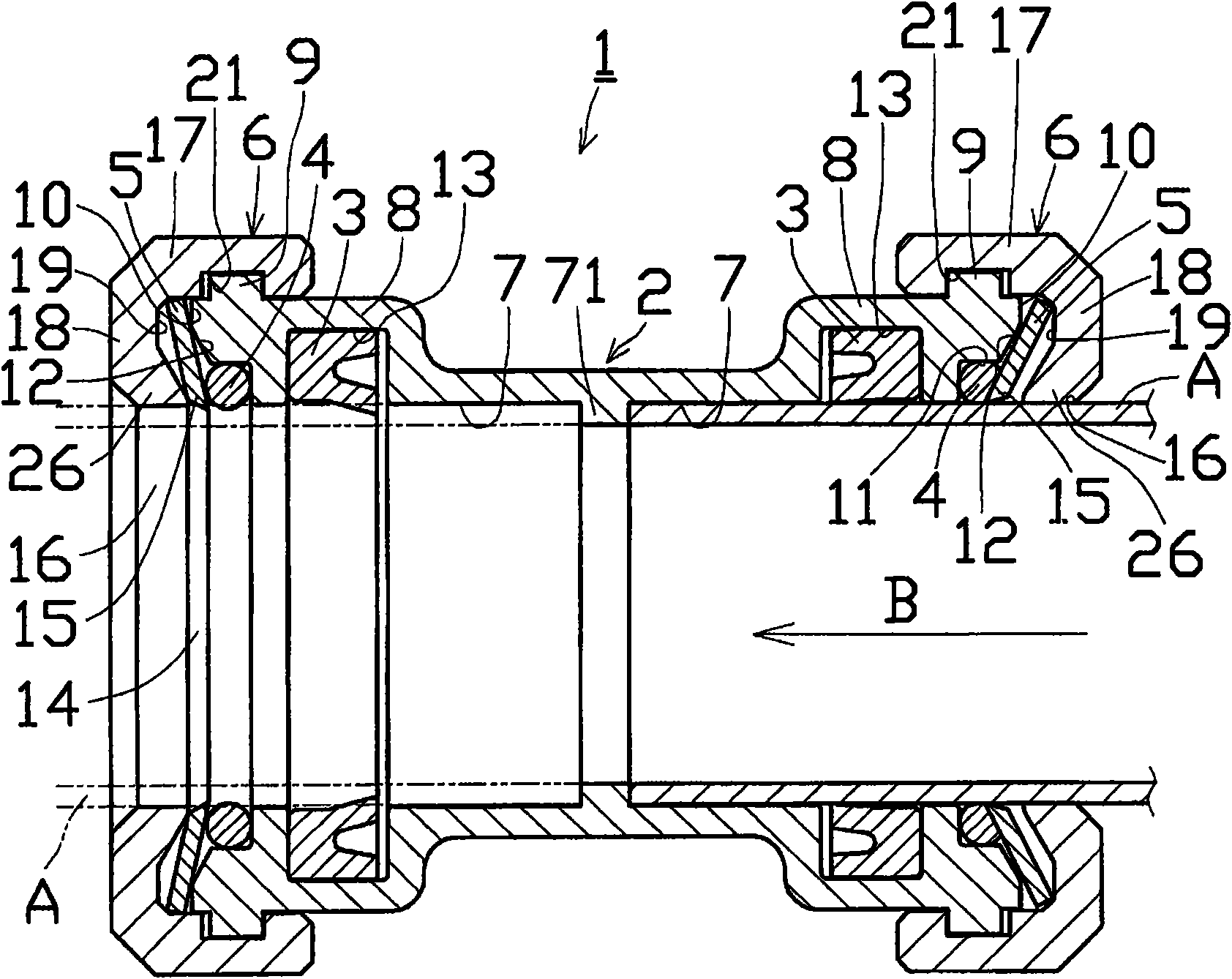

[0040] For the specific implementation of the present invention, while referring to the following appended Figure 1 side to explain.

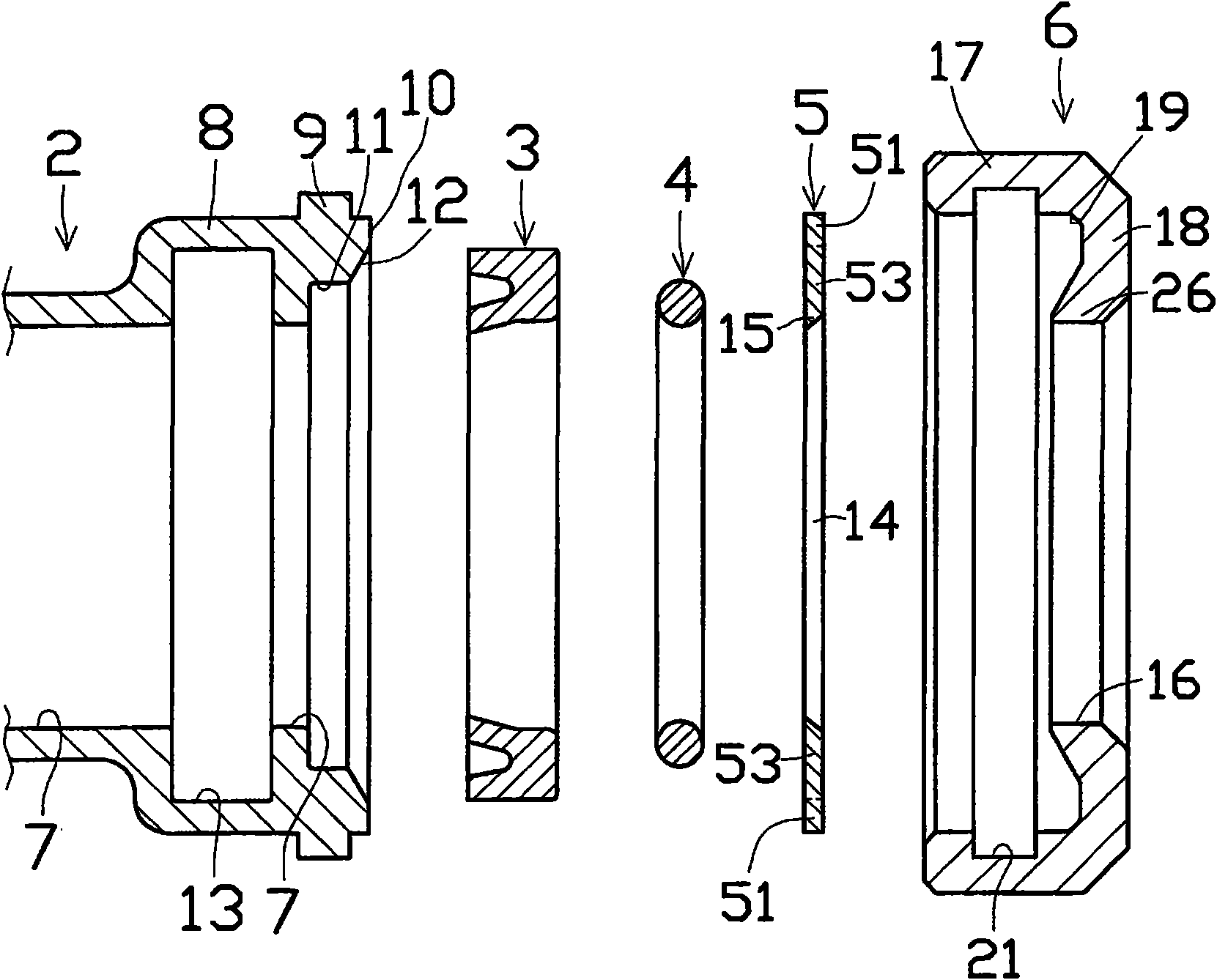

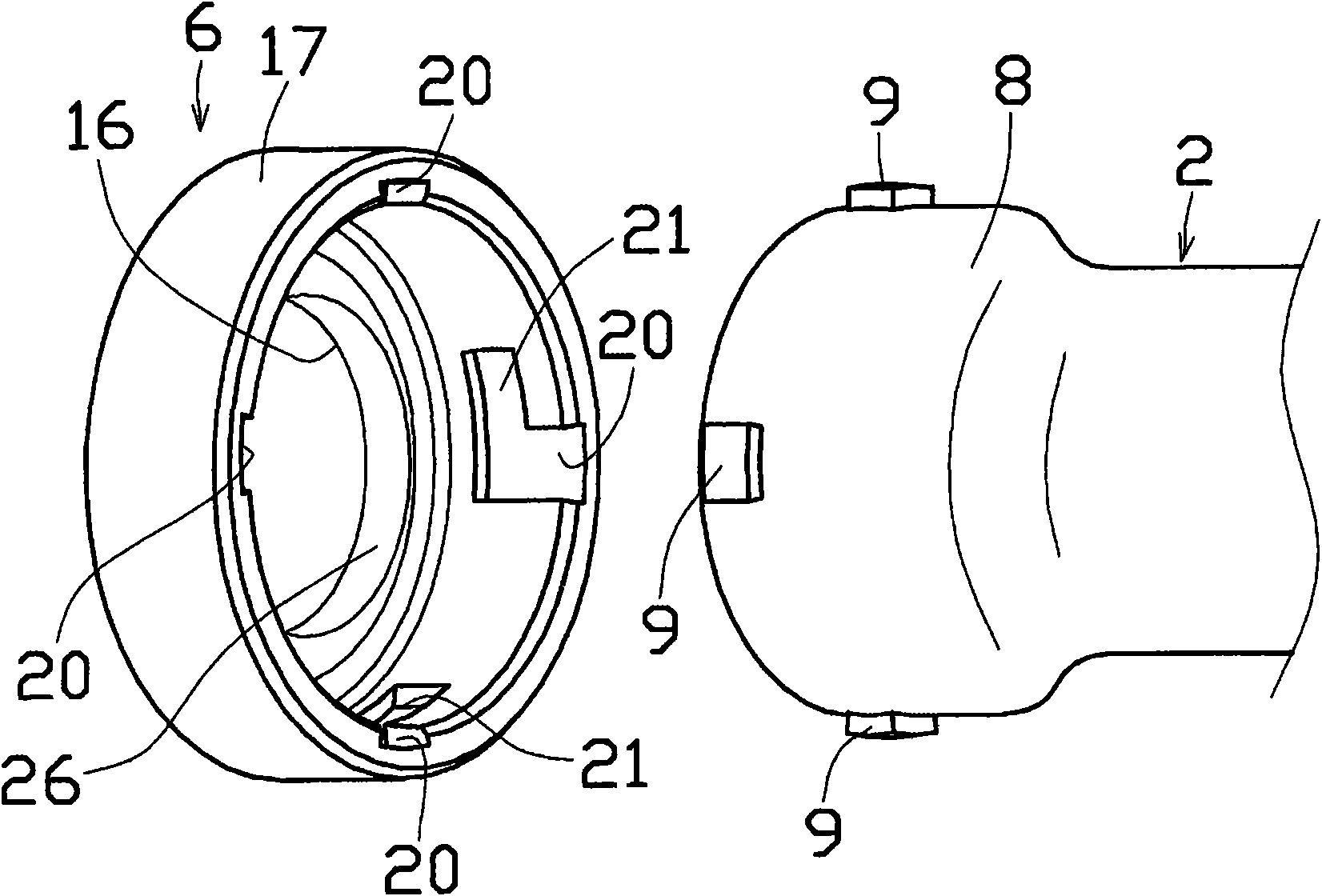

[0041] The first embodiment of the in-line pipe joint 1 for piping according to the present invention is as follows: Figure 1~3 As shown, the joint body 2, the rubber gasket 3, the o-ring 4, the locking ring 5 and the locking ring bracket 6 are the main structural elements.

[0042] A diameter-enlarged portion 8 is formed on the outer periphery of the opening side end of the pipe insertion hole 7 in the center of the joint body 2, and a plurality of locking ring brackets 6 protrude from the outer peripheral surface at predetermined intervals. The engaged engaging protrusion 9 . In addition, on the inner periphery of the opening-side end surface 10, a cutout portion 11 for accommodating the O-ring 4 is formed so as to open to the pipe insertion hole 7 and the opening-side end surface 10, and if necessary, a cutout portion 11 is formed where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com