High-frequency pulse crude oil dehydration transformer

A high-frequency pulse, crude oil dehydration technology, applied in magnetic bias transformers, transformer/inductor coils/windings/connections, electrical separation of liquids, etc., can solve problems such as large waveform distortion, large eddy current loss, and poor insulation capacity , to achieve the effect of reducing high frequency loss, enhancing load capacity and excellent magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

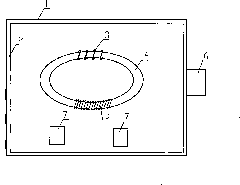

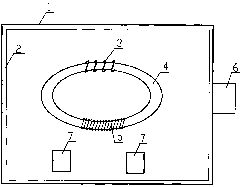

[0015] As shown in Figure 1, the external voltage is 500V, the frequency is 5000Hz-50000Hz (steplessly adjustable), and the duty cycle is 10%-90% (steplessly adjustable). The high-frequency pulse electricity passes through the low-voltage explosion-proof of high-frequency pulse crude oil dehydration transformer. The incoming line interface 6 is connected to the primary coil 3 of the transformer, and the high-frequency pulse electricity generates a high-frequency pulse electromagnetic field through the primary coil of the transformer, and the electromagnetic field is transmitted to the secondary coil 5 through the iron core 4, because the number of turns of the secondary coil 5 is equal to that of the primary coil 3 60 times the number of turns, so a high-frequency pulse electricity with a voltage of 30000V is induced in the secondary coil 5 . Finally, the output voltage is 30000V and the frequency is 5000Hz-50000Hz and the duty cycle is 10%-90% of the high-frequency high-voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com