Multifunctional dynamic pollution evaluation device of coalbed drilling fluid

A pollution evaluation and drilling fluid technology, applied in the direction of measuring devices, earthwork drilling, wellbore/well components, etc., can solve the problems of single research and inability to meet actual production, and achieve stress effect avoidance, experimental software modularization, and experimental The effect of data normalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

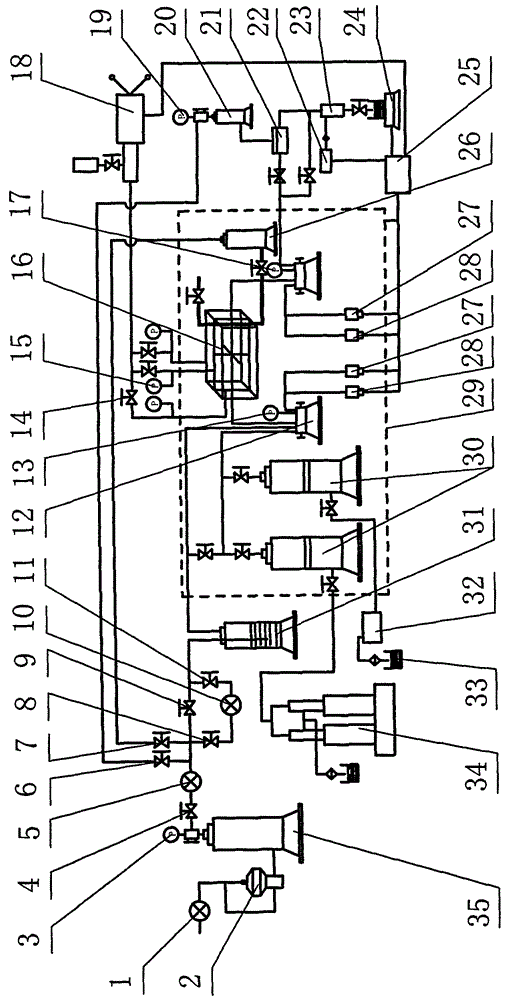

[0017] The multifunctional coal seam drilling fluid dynamic pollution evaluation device consists of a low-pressure pressure regulating valve 1, a gas booster pump 2, a gas high-pressure gauge 3, a high-pressure pressure regulating protection valve 4, a high-pressure pressure reducing valve 5, a back pressure boosting valve 6, and mud pollution Valve 7, low pressure regulating protection valve 8, high pressure boosting valve 9, low pressure pressure reducing valve 10, low pressure boosting valve 11, six-way valve seat 12, inlet pressure gauge 13, axial pressure boosting valve 14, axial pressure gauge 15. Triaxial stress coal core holder 16, outlet pressure gauge 17, metering axial pressure pump 18, back pressure gauge 19, back pressure regulator 20, back pressure valve 21, gas mass flow meter 22, gas-water separator 23. Electronic balance 24, computer acquisition board 25, mud container 26, low-pressure pressure sensor 27, high-pressure pressure sensor 28, oven 29, high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com