Processing process of woven fabric with one-way quick moisture conducting composite structure

A technology of composite structure and woven fabrics, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of unused woven fabrics, achieve the effect of increasing evaporation speed and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

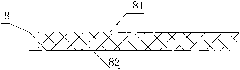

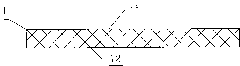

[0037] Such as figure 1 As shown, when the fabric is a single-layer fabric 8, the outer surface adopts a hydrophilic surface 81 made of raw materials with good hygroscopicity, and the inner surface adopts a hydrophobic surface 82 made of raw materials with slightly poor hygroscopicity. figure 2 As shown, the fabric of this embodiment is a single-layer fabric 1, using a one-way moisture-conducting model with different hygroscopic properties of the warp and weft yarns in the one-way moisture-conducting model, the warp yarn is Tencel, and the weft yarn is Cooldry, PLA / cotton blended yarn and stainless steel fiber bag Core yarn composition. Because the hygroscopicity of the warp is better than that of the weft, the outer surface of the fabric is the warp support surface 11, and the inner surface is the weft support surface 12, so the fabric weave selects 5 / 3 or 8 / 3 warp satin. The weaving process uses a rapier loom, through warping, sizing, threading and knotting, weaving into g...

Embodiment 2

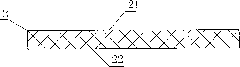

[0039] Such as image 3 As shown, the fabric of this embodiment is a single-layer fabric 2, using a one-way moisture-conducting model with different hygroscopic properties of the warp and weft yarns in the one-way moisture-conducting model. The weft yarn is Tencel, and the warp yarn is Cooldry, PLA / cotton blended yarn and stainless steel fiber. Core yarn composition. Because the hygroscopicity of the weft yarn is better than that of the warp yarn, the outer surface of the fabric should be the weft support surface 21, and the inner surface should be the warp support surface 22, so the fabric weave selects 5 / 3 or 8 / 3 weft surface satin weave. The weaving process uses a rapier loom, through warping, sizing, threading and knotting, weaving into gray cloth, and then the woven gray cloth is turned over and seamed, singeing, desizing, refining and bleaching, dyeing, softening and setting. The finishing step completes the entire process.

Embodiment 3

[0041] Such as Figure 4 The fabric shown is double-weft fabric 3 in a single-layer fabric, using double-weft one-way moisture-wicking fabric model, using Cooldry or PLA / cotton blended yarn for the warp yarn, and the weft yarn is the hydrophobic layer or water-conducting layer 32 from the inside to the outside. (inner surface), select fast-conducting polyester or fast-conducting polyester / cotton blended yarn with good moisture conductivity for use; hydrophilic layer 31 (outer surface), select hygroscopicity better tencel for use, and weave is weft double weave. The weaving process uses a rapier loom, through warping, sizing, threading and knotting, weaving into gray cloth, and then the woven gray cloth is turned over and seamed, singeing, desizing, refining and bleaching, dyeing, softening and setting. The finishing step completes the entire process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com