Micro-carbon aluminum-killed steel with low yield ratio and good deep drawing property and preparation method thereof

A low yield ratio, aluminum-killed steel technology, applied in metal rolling, manufacturing tools, temperature control, etc., can solve the problem of reducing material strength, reducing the mass fraction of solid solution nitrogen in steel, and reducing the fine grain strengthening of ferrite structure and AlN precipitation strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

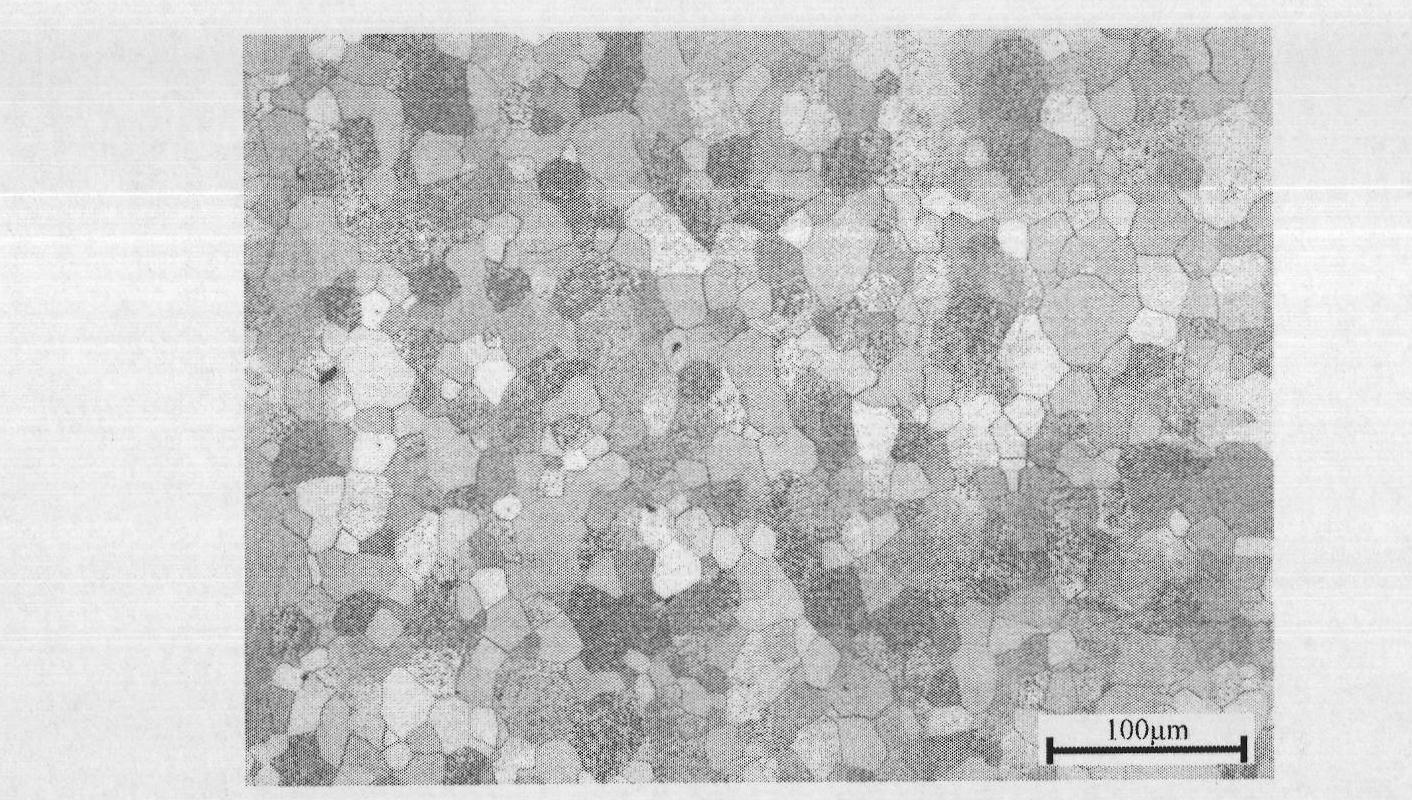

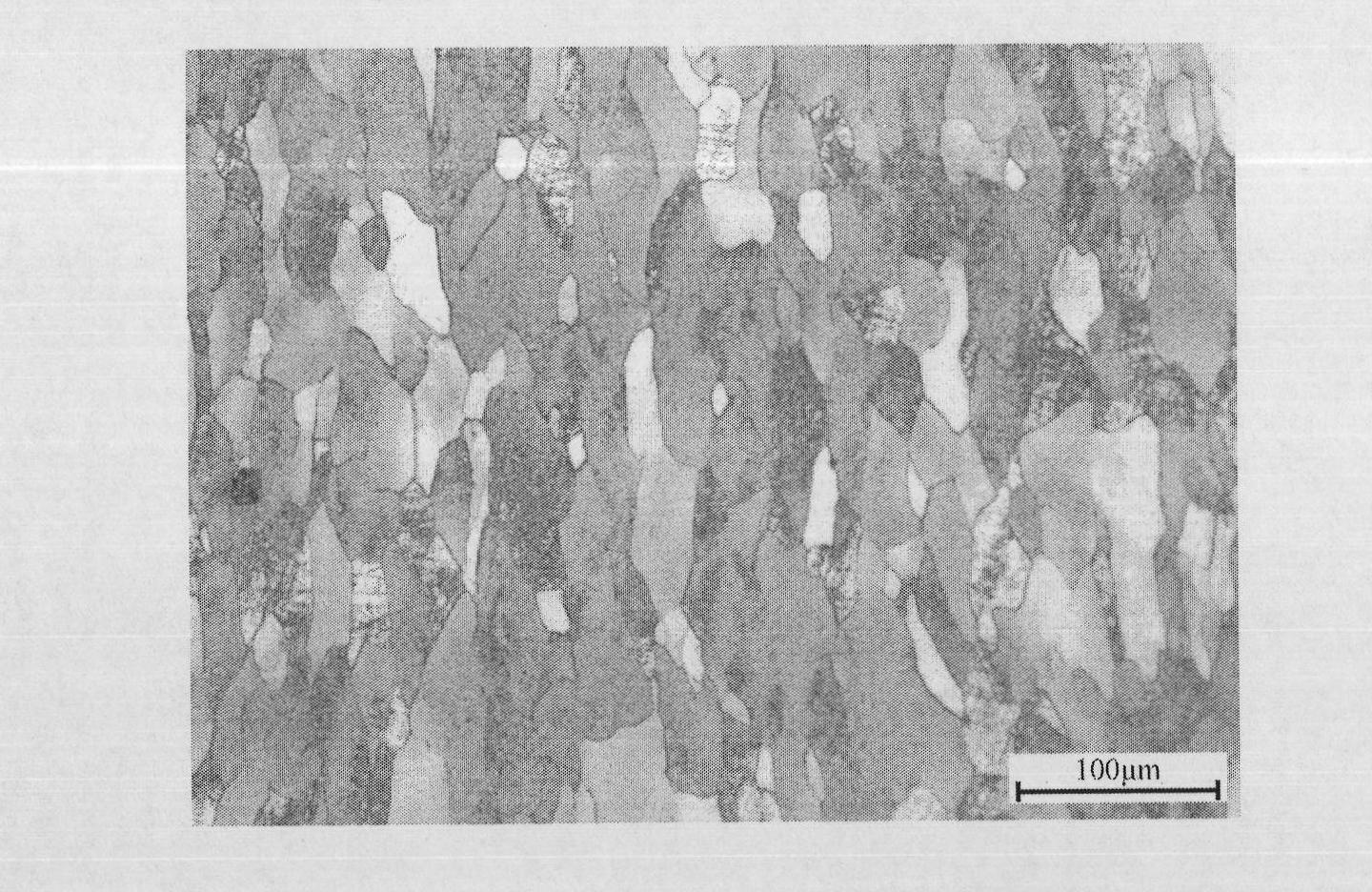

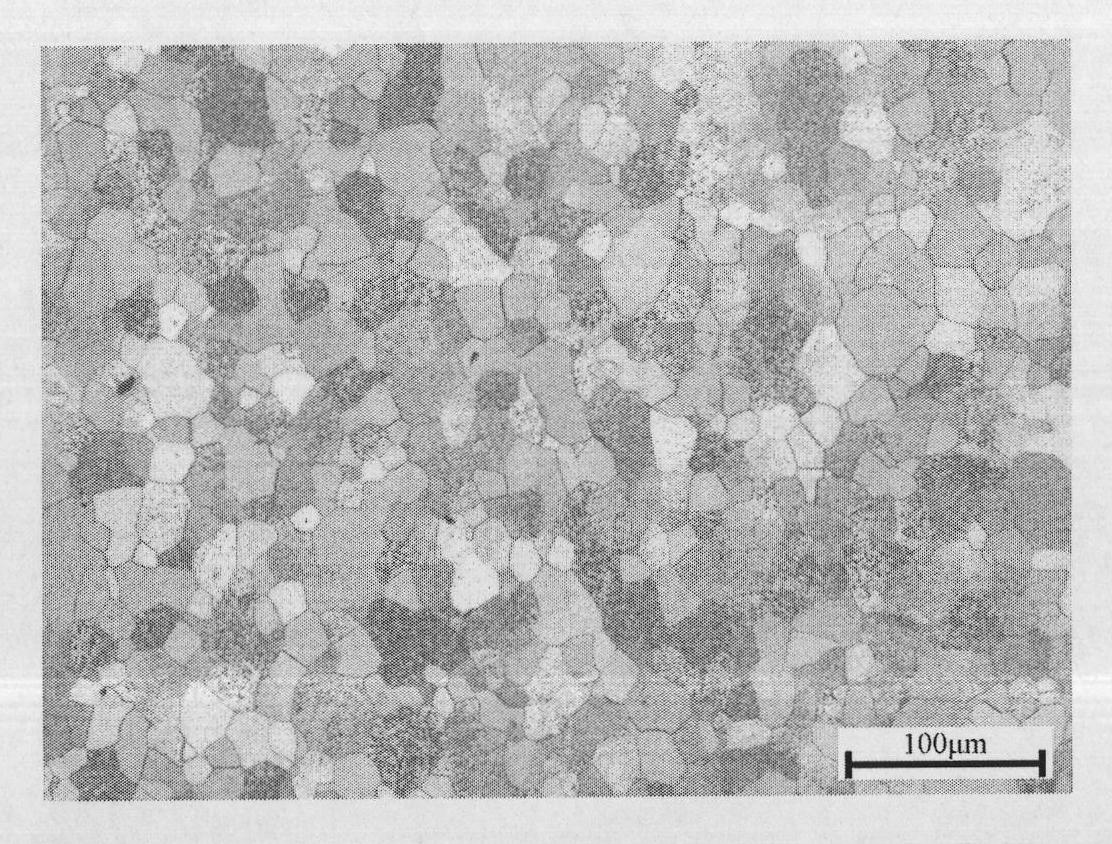

[0021] According to the composition designed in Table 1, use a 50Kg vacuum electromagnetic smelting furnace to smelt molten steel that meets the set composition control range and cast it into a billet, and then forge it into a 35mm billet. The forged billet is kept at 1150°C for 60 minutes, and then heated Rolling, the specific hot rolling rolling process is shown in Table 2. The thickness of the steel plate after hot rolling is 3.8mm. The hot-rolled steel plate is pickled and then cold-rolled. The total cold rolling reduction is 70%-85%. The annealing temperature is 810°C, the holding time is 70s, the overaging temperature is 400°C, the holding time is 180s, and then air-cooled to room temperature. The properties of the steel plate produced according to the composition and technology designed in the present invention are shown in Table 3, figure 1 is the metallographic structure of hot-rolled steel plate, figure 2 It is the metallographic structure of annealed steel plate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com