Method for preparing chitosan/polyving alcohol/polylactic acid blended dense membrane

A technology of polyvinyl alcohol and chitosan, which is applied in medical science, absorbent pads, prostheses, etc., can solve the problems of retention and blend film properties that are rarely reported, and achieve good mechanical properties and good water vapor ventilation. Permeability, beneficial to the effect of wound drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

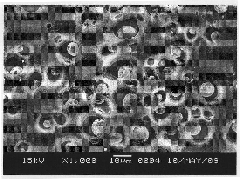

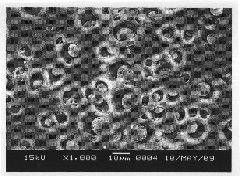

Image

Examples

Embodiment 1

[0024] Dissolve 3g of chitosan in 97g by weight of 2% acetic acid solution at 40°C to form a homogeneous solution. Dissolve 5 g of polylactic acid in 95 g (content ≥ 99 wt %) of dimethyl sulfoxide solution at 25° C. to form a uniform solution. Dissolve 7g of polyvinyl alcohol in 93g of deionized water at 100°C to form a uniform solution. Weigh 11.2g of chitosan solution, 0.6g of polyvinyl alcohol solution and 0.84g of polylactic acid solution, mix together at 25°C, stir for 30min, and defoam. Cast the defoamed mixed solution on polyester film and dry it at room temperature for 4 hours, then vacuum dry and heat-set at 25°C to obtain chitosan: polyvinyl alcohol: polylactic acid with a weight percentage of 8:1:1 Dense films of chitosan / polyvinyl alcohol / polylactic acid blends.

Embodiment 2

[0026] Weigh 12.6g of chitosan solution, 2.7g of polyvinyl alcohol solution and 1.26g of polylactic acid solution respectively, mix together at 25°C, stir for 30min, and defoam. Cast the defoamed mixed solution on polyester film and dry it at room temperature for 4 hours, then vacuum dry and heat-set at 25°C to obtain chitosan: polyvinyl alcohol; the weight percentage of polylactic acid is 6:3:1 Dense films of chitosan / polyvinyl alcohol / polylactic acid blends.

Embodiment 3

[0028] Weigh 11.2g of chitosan solution, 6g of polyvinyl alcohol solution and 1.68g of polylactic acid solution, mix together at 25°C, stir for 30min, and defoam. Cast the defoamed mixed solution on polyester film and dry it at room temperature for 4 hours, then vacuum dry and heat-set at 25°C to obtain chitosan: polyvinyl alcohol: polylactic acid with a weight percentage of 4:5:1 Dense films of chitosan / polyvinyl alcohol / polylactic acid blends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com