Four-step method process for controlling production of building plaster in industrial and fully automatic mode by using citric acid plaster

A technology of citric acid gypsum and building gypsum, which is applied in the field of four-step process, can solve the problems of short residence time, uneven heating of materials, and easy sticking to the wall of the cylinder, and achieve excellent product performance, broad promotion prospects, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

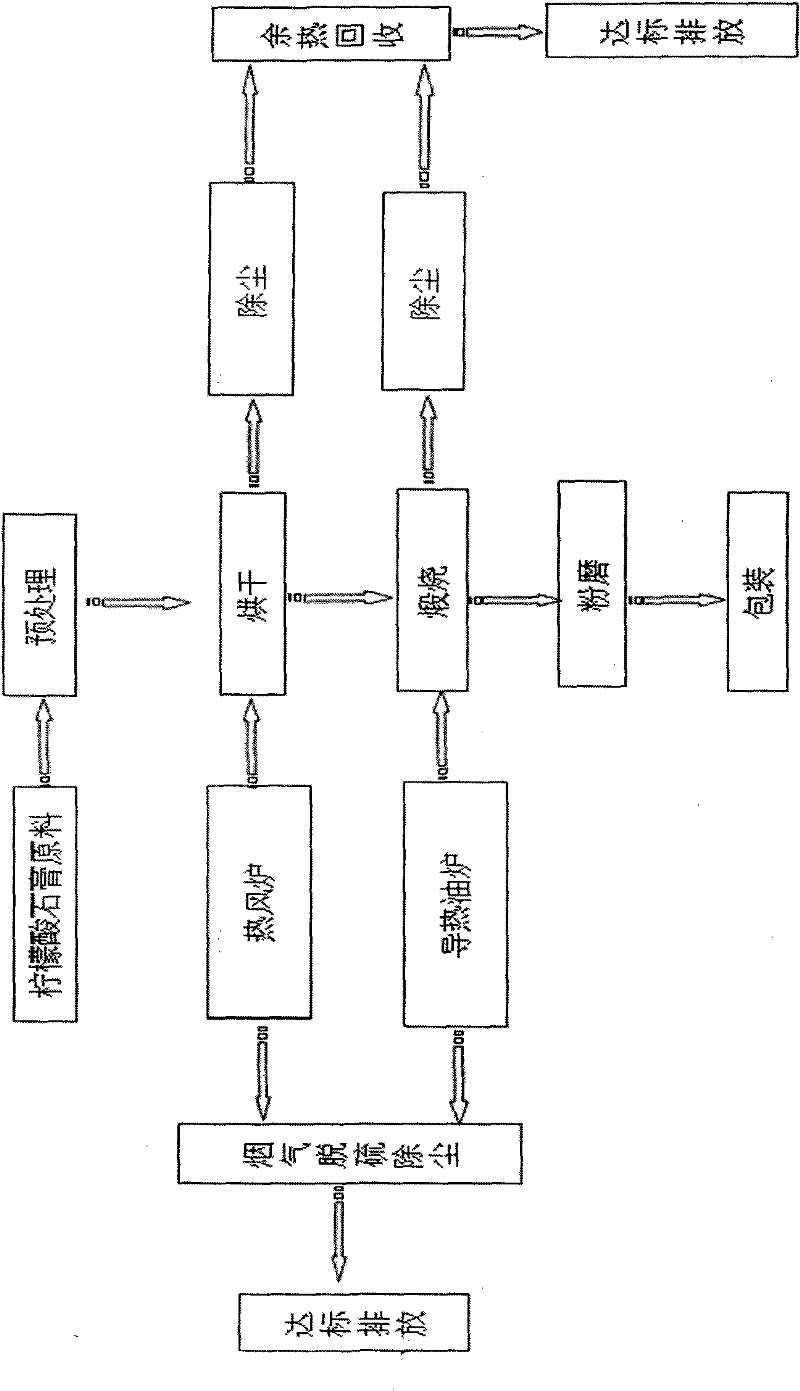

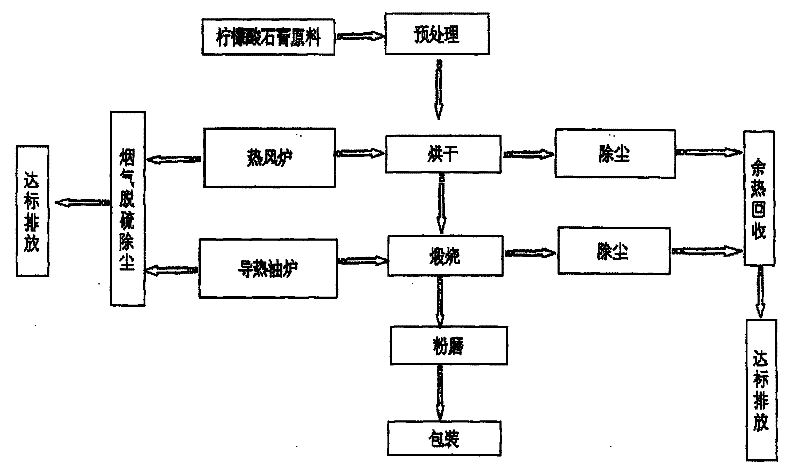

Method used

Image

Examples

Embodiment 1

[0025] A kind of four-step method utilizing citric acid gypsum industrialized automatic control to produce building gypsum, its steps are as follows:

[0026] 1. The citric acid gypsum raw material is washed and pretreated, and a trace amount of calcium oxide is added thereto, and the pH value of the raw material after treatment is 6.62;

[0027] 2. The processed raw materials are quantitatively sent to the drum dryer by the conveyor belt, the drying time is 28 minutes, the drying temperature is controlled at 450 °C, and the attached water content after drying is 3.42%;

[0028] 3. Transport the dried material to the fluidized calciner;

[0029] 4. The calcination temperature of the calcination furnace is 180°C, the calcination time is 47 minutes, and the crystal water content of the discharged material is 3.65%;

[0030] 5. Send the calcined plaster of paris to a ball mill for grinding;

[0031] 6. Send the ground gypsum powder into the finished product warehouse by the con...

Embodiment 2

[0034] A kind of four-step method utilizing citric acid gypsum industrialized automatic control to produce building gypsum, its steps are as follows:

[0035] 1. The citric acid gypsum raw material is washed and pretreated, and a small amount of sodium hypochlorite is added thereto, and the pH value of the raw material after treatment is 7.83;

[0036]2. The processed raw materials are quantitatively sent to the drum dryer by the conveyor belt. The drying time is 25 minutes, the drying temperature is controlled at 480°C, and the attached water content after drying is 5.67%;

[0037] 3. Transport the dried material to the fluidized calciner;

[0038] 4. The calcination temperature of the calcination furnace is 170°C, the calcination time is 45 minutes, and the crystal water content of the discharged material is 4.24%;

[0039] 5. Send the calcined plaster of paris to a ball mill for grinding;

[0040] 6. Send the ground gypsum powder into the finished product warehouse by the...

Embodiment 3

[0043] A kind of four-step method utilizing citric acid gypsum industrialized automatic control to produce building gypsum, its steps are as follows:

[0044] 1. The citric acid gypsum raw material is washed and pretreated, and a small amount of sodium hydroxide and calcium hypochlorite are added thereto, and the pH value of the raw material after treatment is 7.74;

[0045] 2. The processed raw materials are quantitatively sent to the drum dryer by the conveyor belt, the drying time is 23 minutes, the drying temperature is controlled at 500 °C, and the attached water content after drying is 2.58%;

[0046] 3. Transport the dried material to the fluidized calciner;

[0047] 4. The calcination temperature of the calcination furnace is 175°C, the calcination time is 42 minutes, and the crystal water content of the discharged material is 4.33%;

[0048] 5. Send the calcined plaster of paris to a ball mill for grinding;

[0049] 6. Send the ground gypsum powder into the finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com