Right-angled distribution engine with suspension piston

A piston engine and piston technology, applied to internal combustion piston engines, engine components, combustion engines, etc., can solve the problems affecting the intake and exhaust valve intake and exhaust area, the reduction of the emission performance of the two-stroke engine, the oil entering the exhaust port, etc. problems, to achieve the effect of prolonging life, good environmental performance, and increasing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

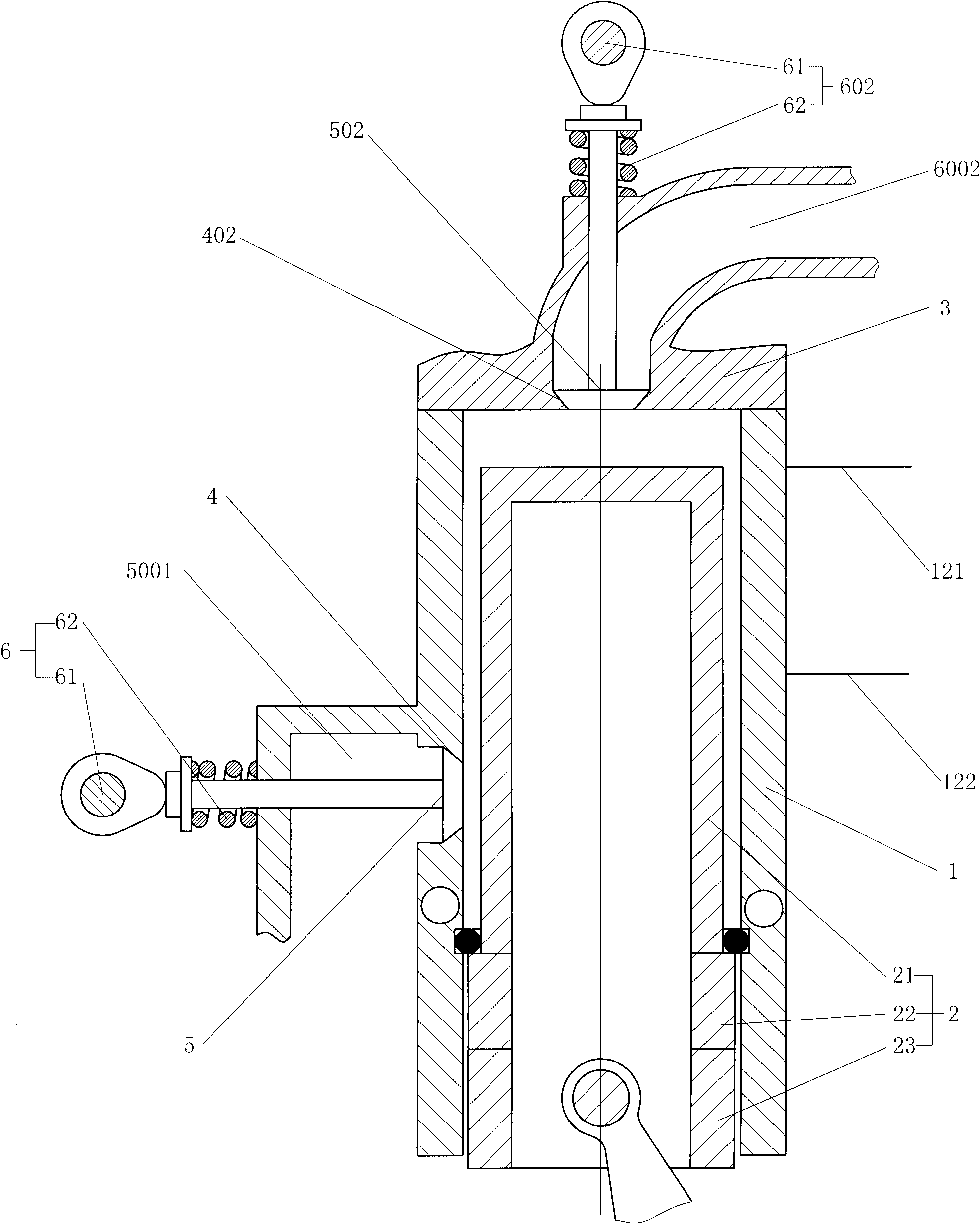

[0052] Such as figure 1 The shown right-angle gas distribution suspension piston engine includes a cylinder 1 and a piston 2, and the piston 2 is fully or partially arranged in the cylinder 1, and the cylinder top dead center 121 on the cylinder 1 corresponding to the piston top dead center of the piston 2 and the The piston 2 and the cylinder 1 are suspended or quasi-suspended within the entire stroke range or part of the stroke range between the cylinder bottom dead center 122 on the cylinder 1 corresponding to the piston bottom dead center of the piston 2, and the piston 2 is suspended or quasi-suspended. A lower side wall air distribution passage 5001 is provided on the side wall of the cylinder 1 constituting the quasi-floating setting relationship, and a lower side wall air distribution seat is provided on the side wall of the cylinder 1 in each lower side wall air distribution passage 5001 4. A lower side wall gas distribution valve body 5 is set at each lower side wall...

Embodiment 2

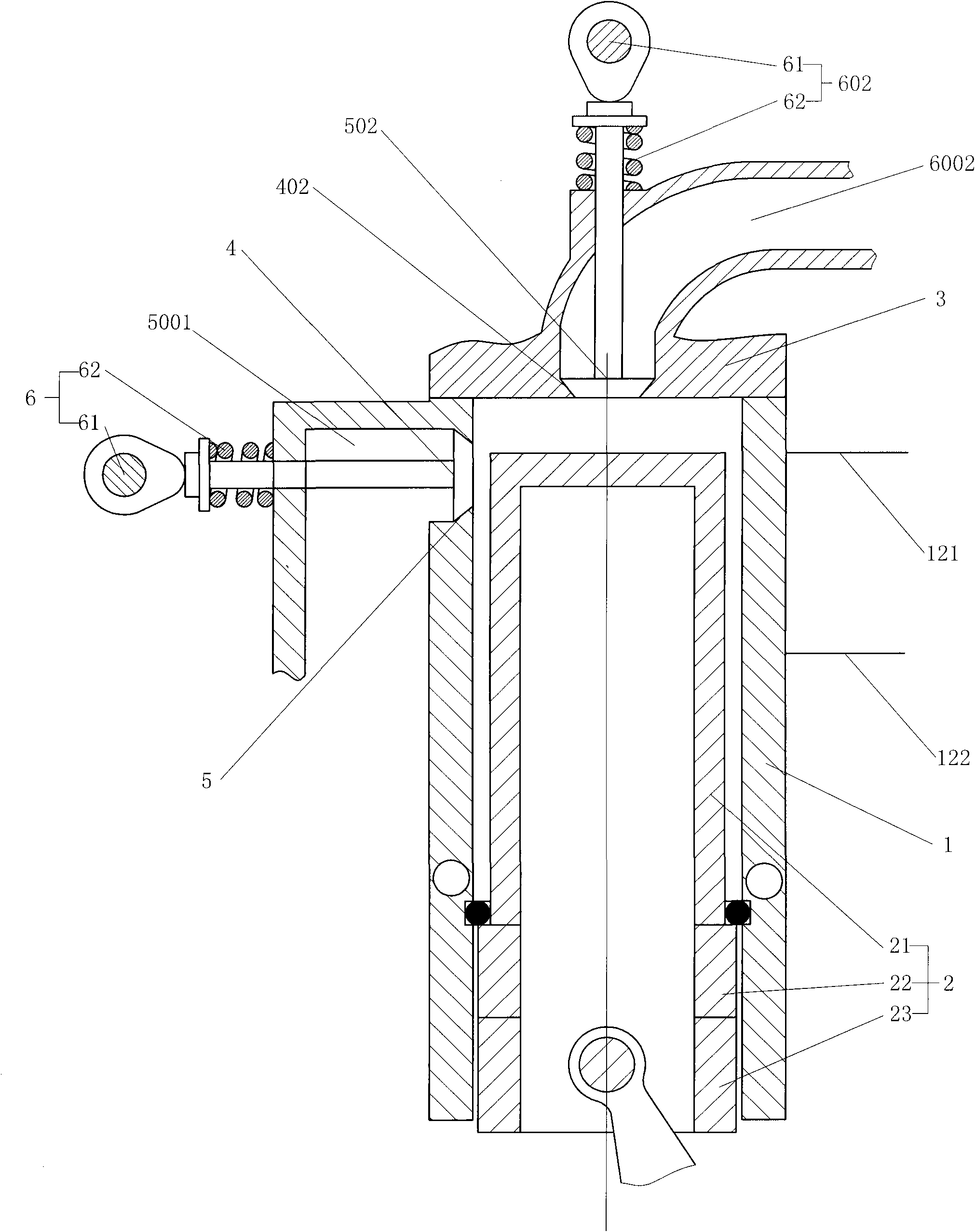

[0055] Such as figure 2 The difference between the shown right-angle air distribution suspension piston engine and Embodiment 1 is that the right-angle air distribution suspension piston engine is a four-stroke engine, and the lower side wall air distribution channel 5001 is located in a suspension setting or quasi-suspension setting relationship with the piston 2. Cylinder 1 constitutes the area at the top dead center 121 of the cylinder or on the side wall near the top dead center 121 of the cylinder.

Embodiment 3

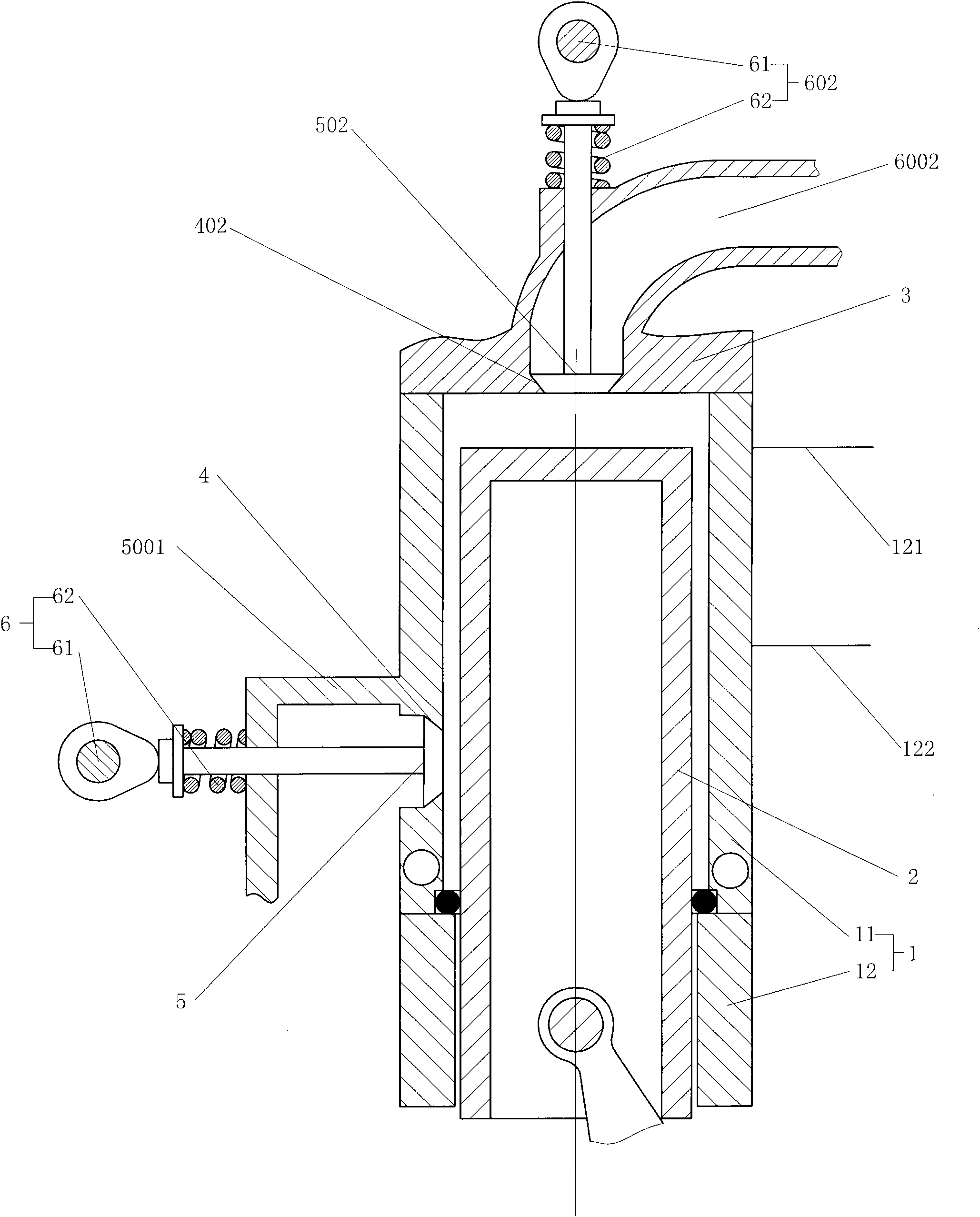

[0057] Such as image 3 The shown right-angle air distribution suspension piston engine differs from Embodiment 1 in that the piston 2 is designed as an integrated structure, the cylinder 1 is made of the cylinder suspension section 11 and the cylinder sealing section 12, and the cylinder suspension section 11 and the piston 2 Suspension setting or quasi-suspension setting, the cylinder sealing section 12 is in sealing and sliding contact with the piston 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com