Construction method for rapid construction of support cast-in-situ continuous beam

A construction method and cast-in-place technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve problems such as long time and inability to meet construction needs, and achieve the effect of saving construction time and ensuring the quality of beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

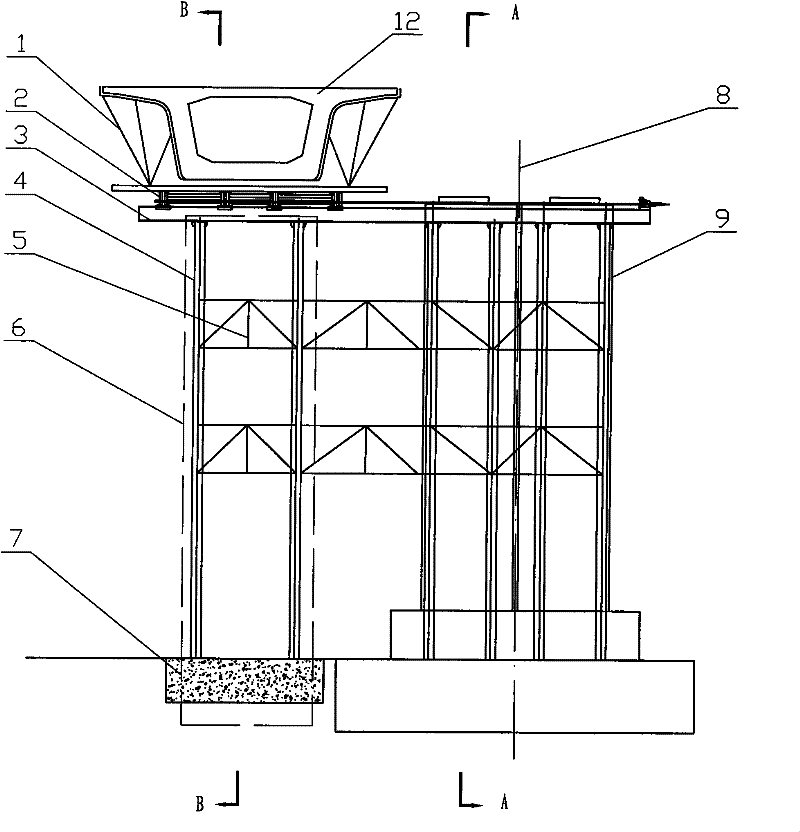

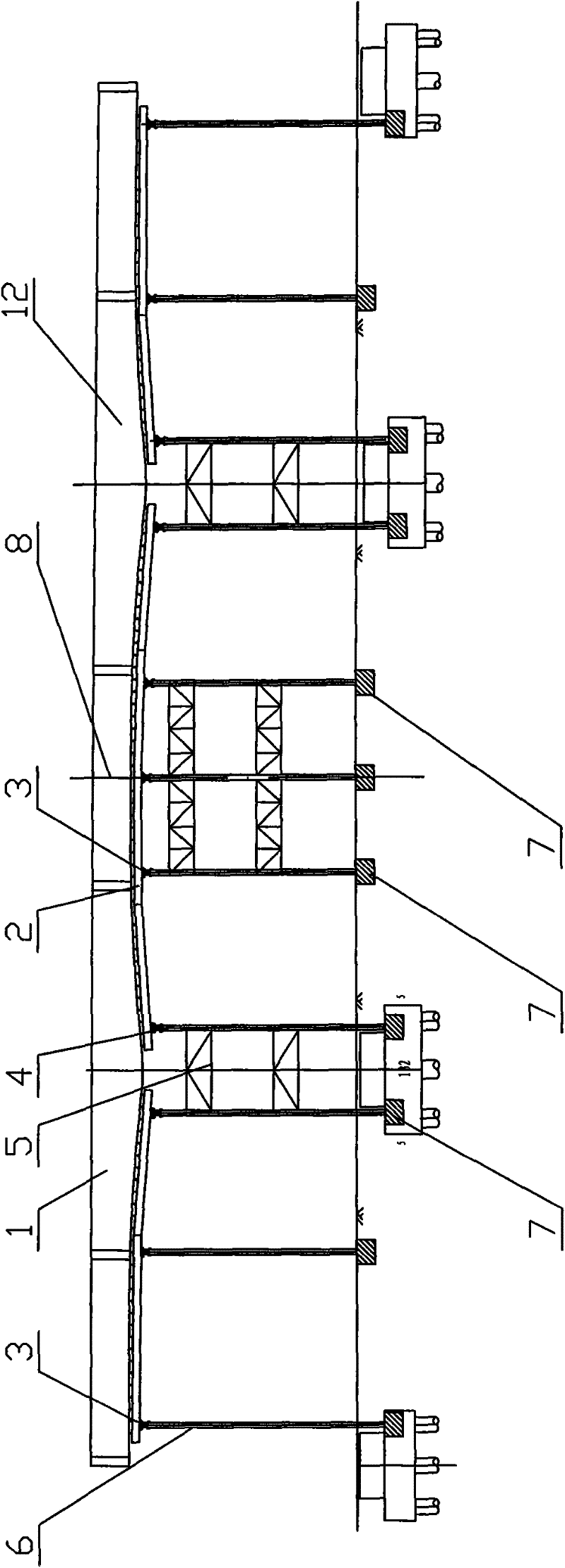

[0020] Depend on figure 1 , figure 2 , image 3 with Figure 4 A construction method for rapid construction of cast-in-place continuous beams with brackets shown, the construction steps are:

[0021] Next to the pier, support 6 is installed next to the pier, and the support 6 next to the pier is carried out in parallel with the foundation construction of the bridge. Build bridge support 9. When the support 6 next to the pier is constructed, the strip foundation 7 is first established, and the steel pipe columns 4 are set up on the strip foundation 7. The steel pipe columns 4 are connected by the connection system 5, and the steel pipe columns 4 utilize the pre-embedded pier body 10 during foundation construction. items connected to it. Set up a pile top distribution beam 3 as a slideway at the top of the steel pipe column 4 between the pier side support 6 and the bridge position support 9, then set up a base formwork platform 2 on the pile top distribution beam 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com