Blast furnace bell-less furnace top failure diagnosis forecasting system

A technology of fault diagnosis and material-free bell, which is applied in the direction of bell and funnel arrangement, etc., can solve problems such as failure to find faults in time, hidden dangers to personal safety, and dangers to point-check equipment, so as to achieve fault pre-treatment and prevent over-repair or disrepair , The effect of reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the system features of the solution, the solution is described below through a specific implementation manner.

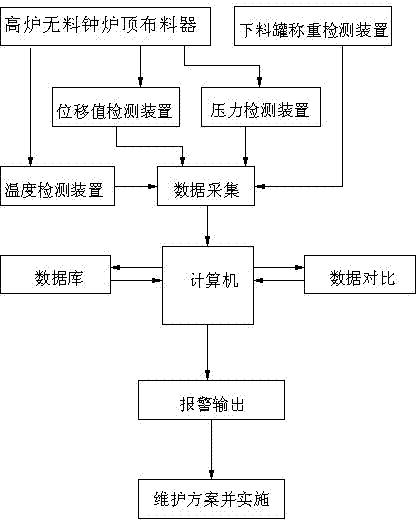

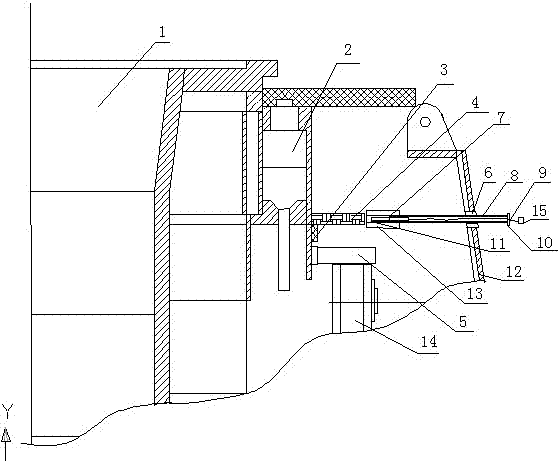

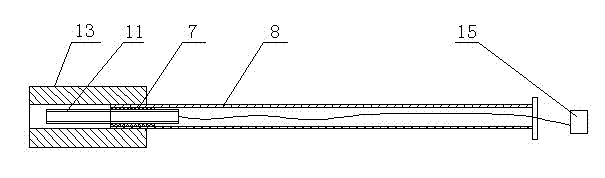

[0021] A blast furnace top fault diagnosis and prediction system without material bell. In addition to the detection device of conventional equipment, its main invention is that a furnace temperature detection device and a furnace pressure detection device large gear disc are installed on the blast furnace top distributor. The displacement value detection device between the relatively stationary gear box shell and the weighing detection device for the furnace top unloading tank;

[0022] Among them, the temperature detection device in the furnace is used to detect the temperature in the furnace, and the pressure detection device in the furnace is used to detect the pressure in the furnace; the weighing detection device for the furnace top discharge tank is used to detect the material weight in the furnace top discharge tank; thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com