Milling technology with obstructed sealing surface

A sealing surface and barrier-free technology, applied in the direction of milling machine equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as oil leakage, product qualification rate is only 20%, air leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

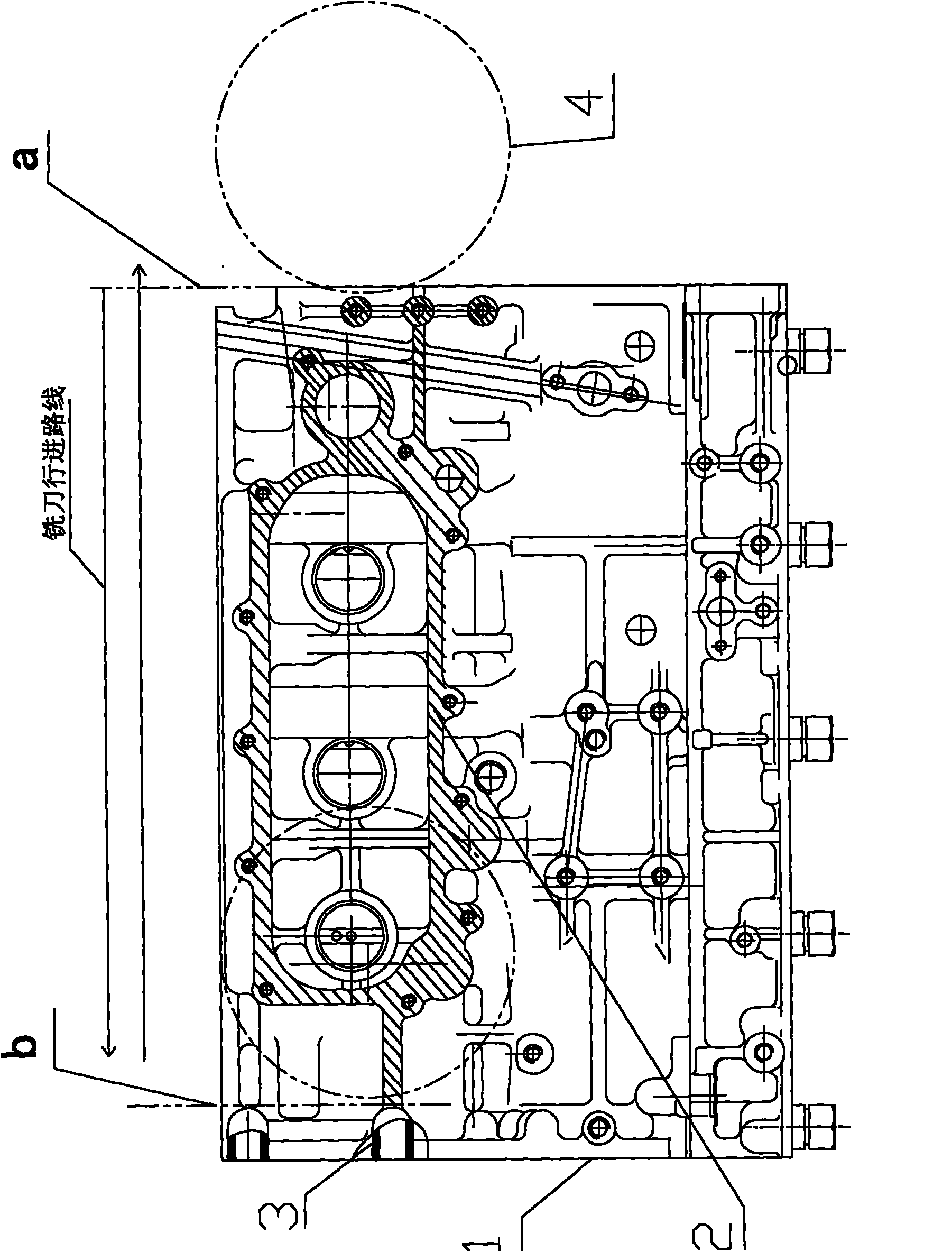

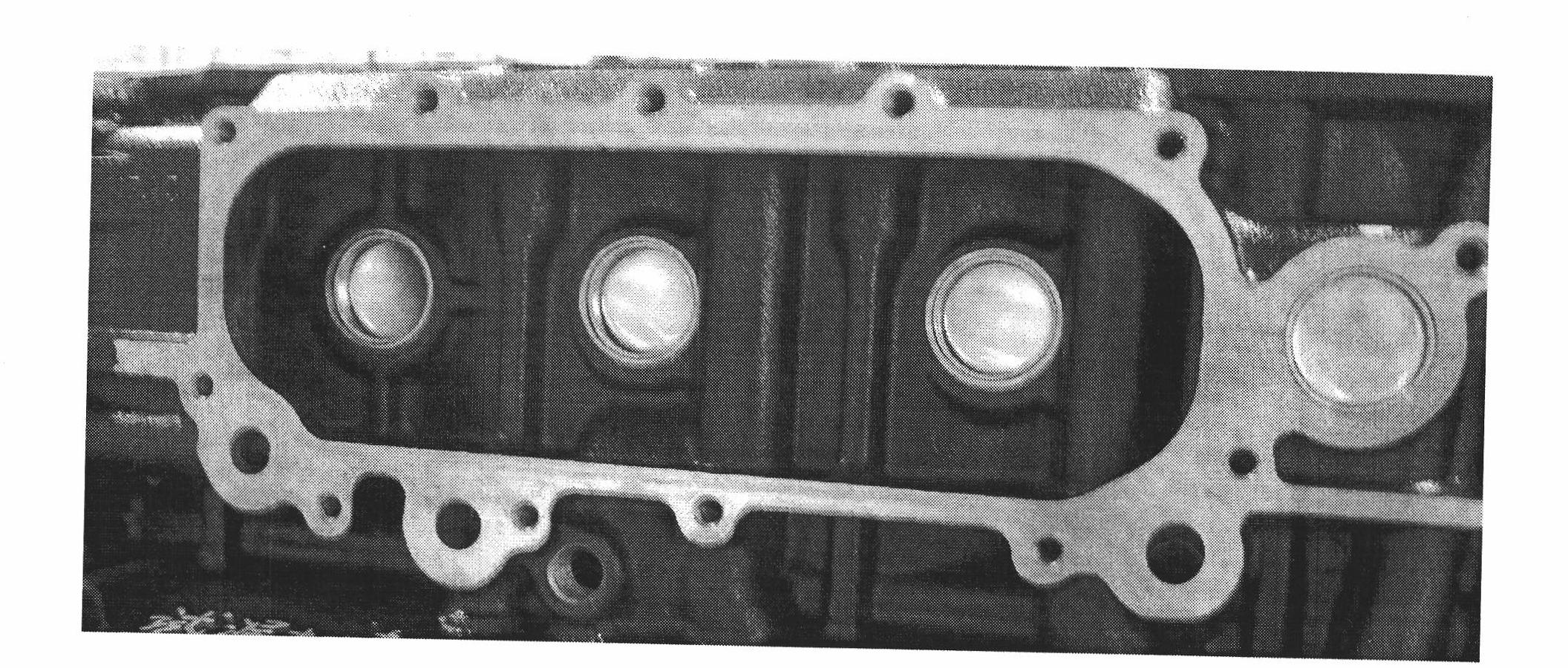

[0014] The process of the present invention will be described in detail below in conjunction with the accompanying drawing 0 by taking the milling finishing of the engine cylinder block sealing surface 1 as an example.

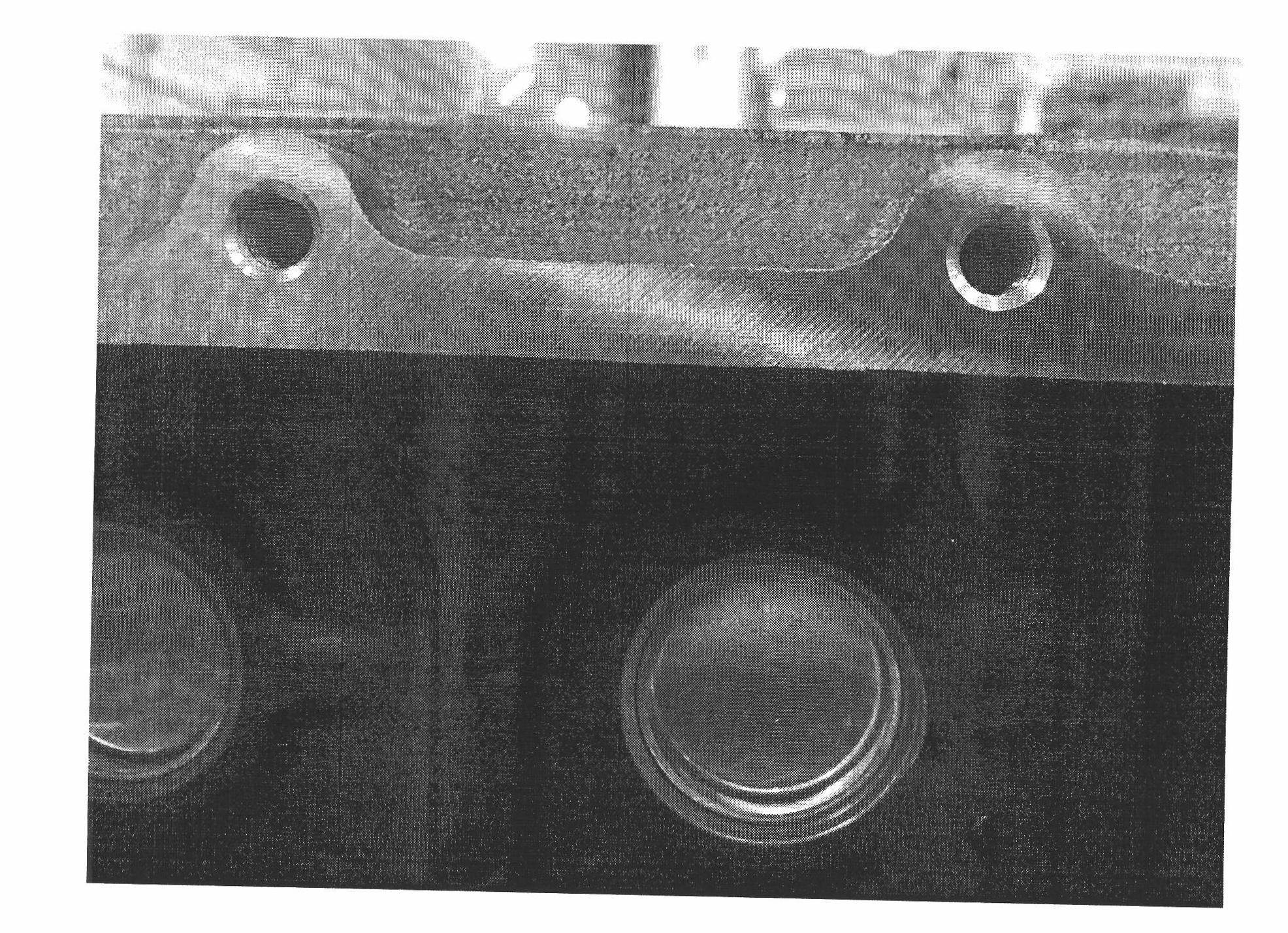

[0015] The cylinder block sealing surface 2 of the engine cylinder block 1 has an oil passage support 3 protruding from the plane, and the oil passage support 3 acts as an obstacle and cannot be processed by ordinary pass-through milling process.

[0016] The processing technology is as follows:

[0017] 1. Start the milling machine, first perform conventional rough milling and semi-finish milling on the sealing surface 2 of the engine cylinder block, the operation method is: after the milling cutter 4 (a CBN cutter) touches the workpiece, start from point a and cut into the workpiece with asymmetrical down milling , before the milling reaches the point b before the oil passage support 2 (that is, before the oil passage support 3), the milling ends, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com