Material-receiving system for band saw gear milling machine

A tooth milling machine and saw band technology, which is applied in the field of band saw band milling machine receiving system, can solve the problems of saw band bending, difficult feeding, low receiving efficiency, etc., achieve flexible selection, improve labor efficiency, The effect of improving the milling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

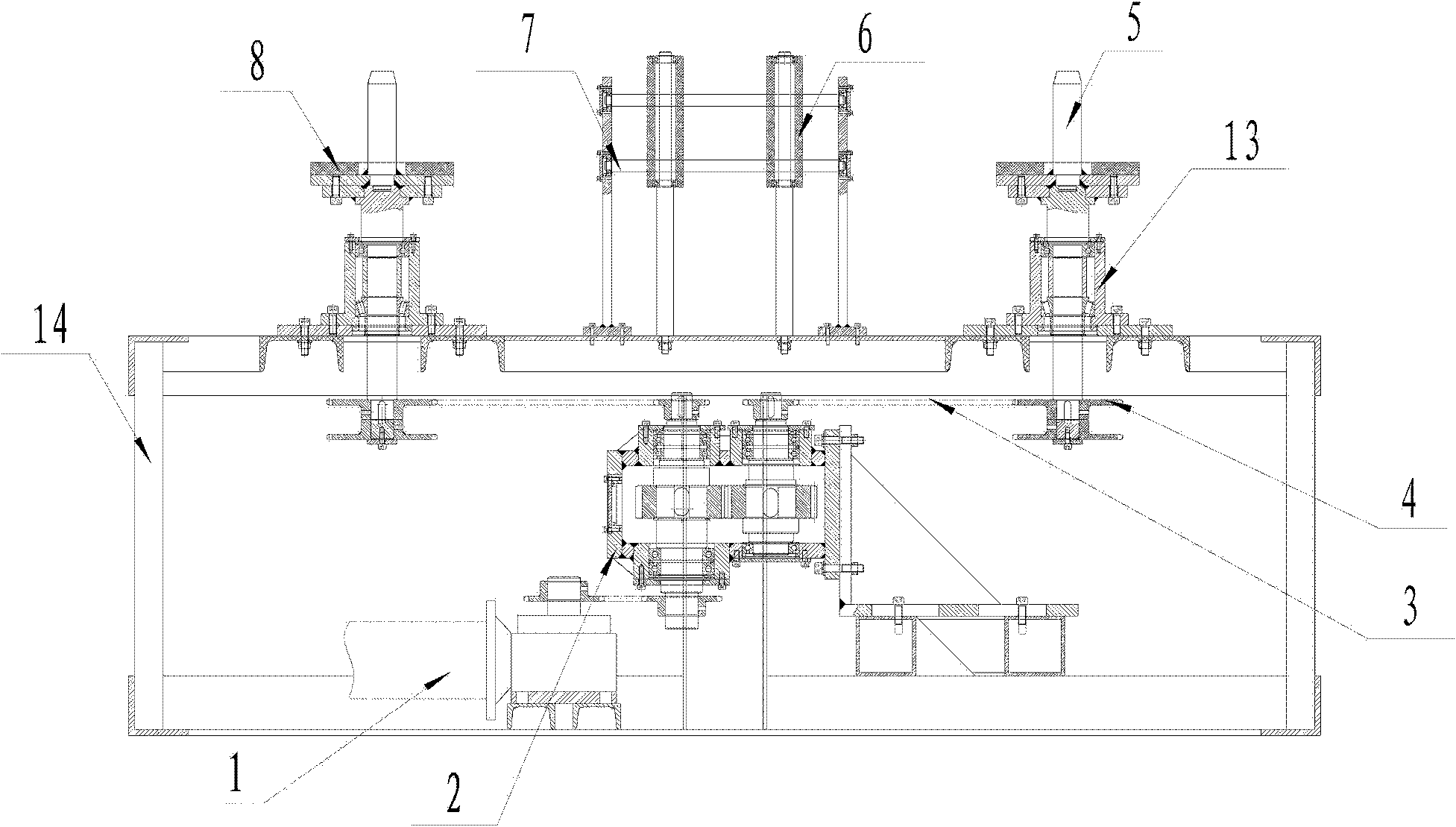

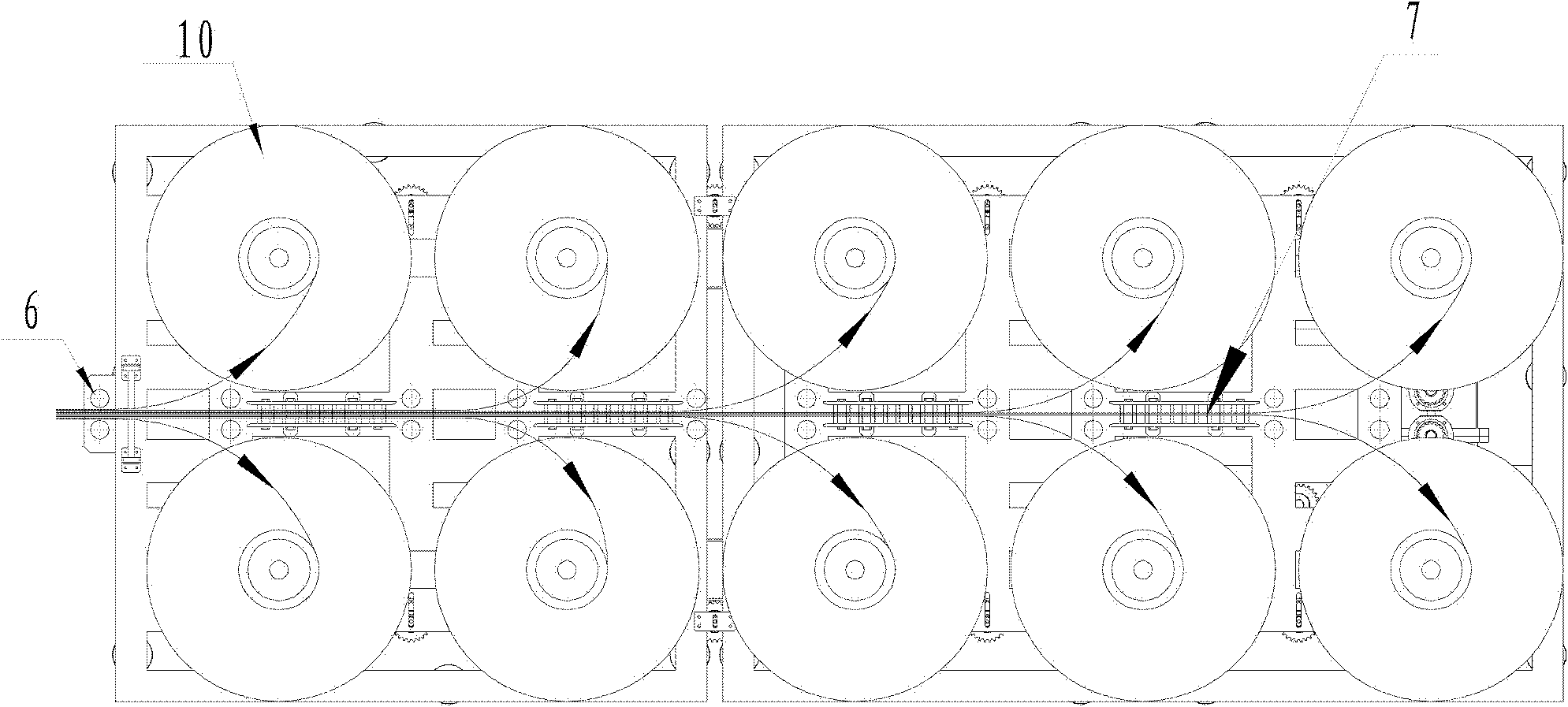

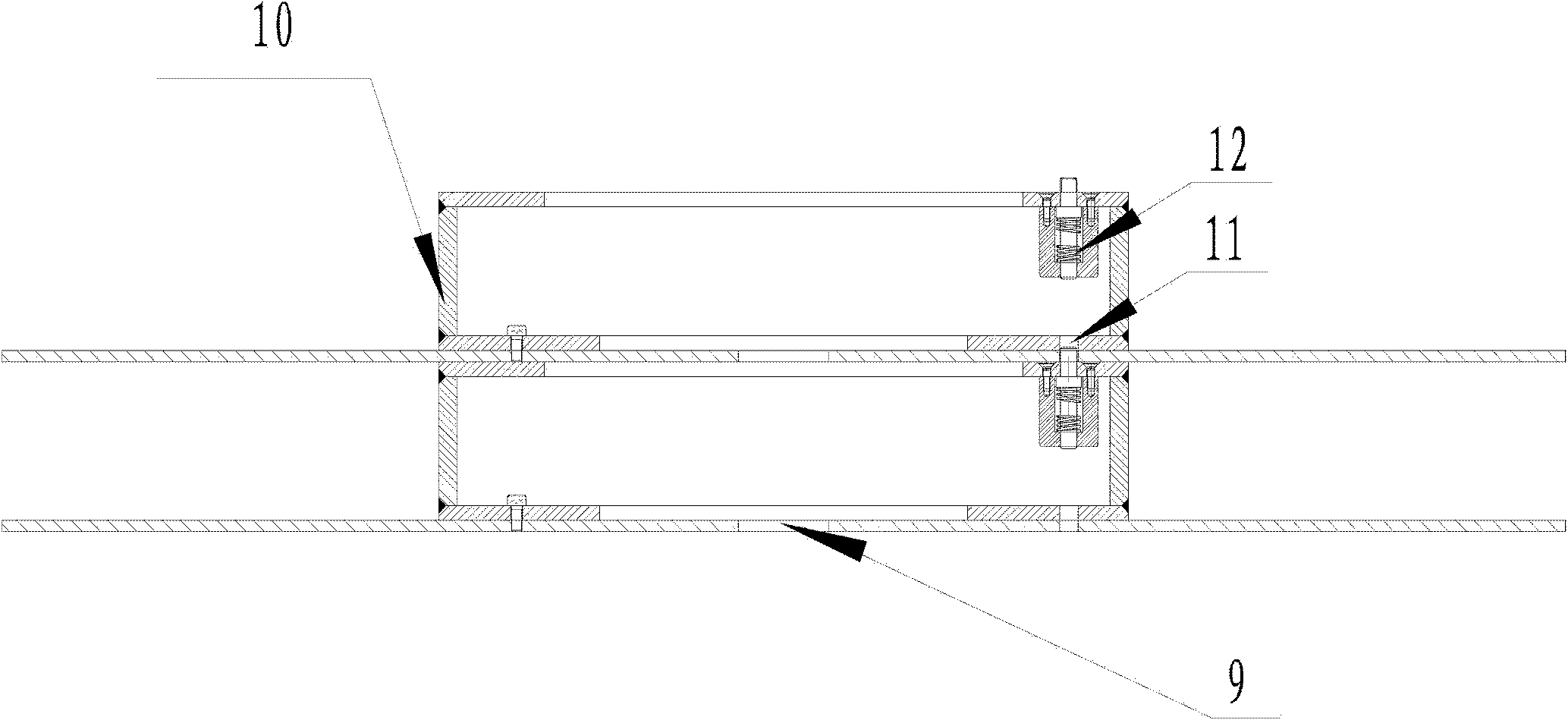

[0024] Such as Figure 1-Figure 3 As shown, a material receiving system for a saw band milling machine includes a base support 14 and a receiving tray 10. The base support 14 is equipped with a motor 1, and a plurality of the receiving trays 10 are arranged on both sides of the top of the base support 14. Parallel and symmetrical two rows of receiving trays, the two rows of receiving trays are located at the same height position to become a layer of receiving trays, between the two rows of receiving trays 10 are provided with a supporting mechanism 7 for supporting the saw band and a limiting saw A stopper wheel 6 with a conveying direction; a positioning hole 9 is provided in the center of each receiving tray 10, and the receiving tray 10 is a layer or multiple layers placed in parallel up and down, and is provided with a positioning shaft 5 vertically passing through each layer. The positioning hole 9 of the material tray 10, the bottom of each positioning shaft 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com