Motor with mixed-flow fan for circulating inner and outer air paths

A technology of mixed-flow fan and air path, which is applied in the field of electric vehicle power drive system, can solve the problems of low peak power and overload capacity, poor low-speed heat dissipation effect, and difficult heat dissipation, and achieve high heat dissipation capacity, excellent heat dissipation ability, and heat dissipation serious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

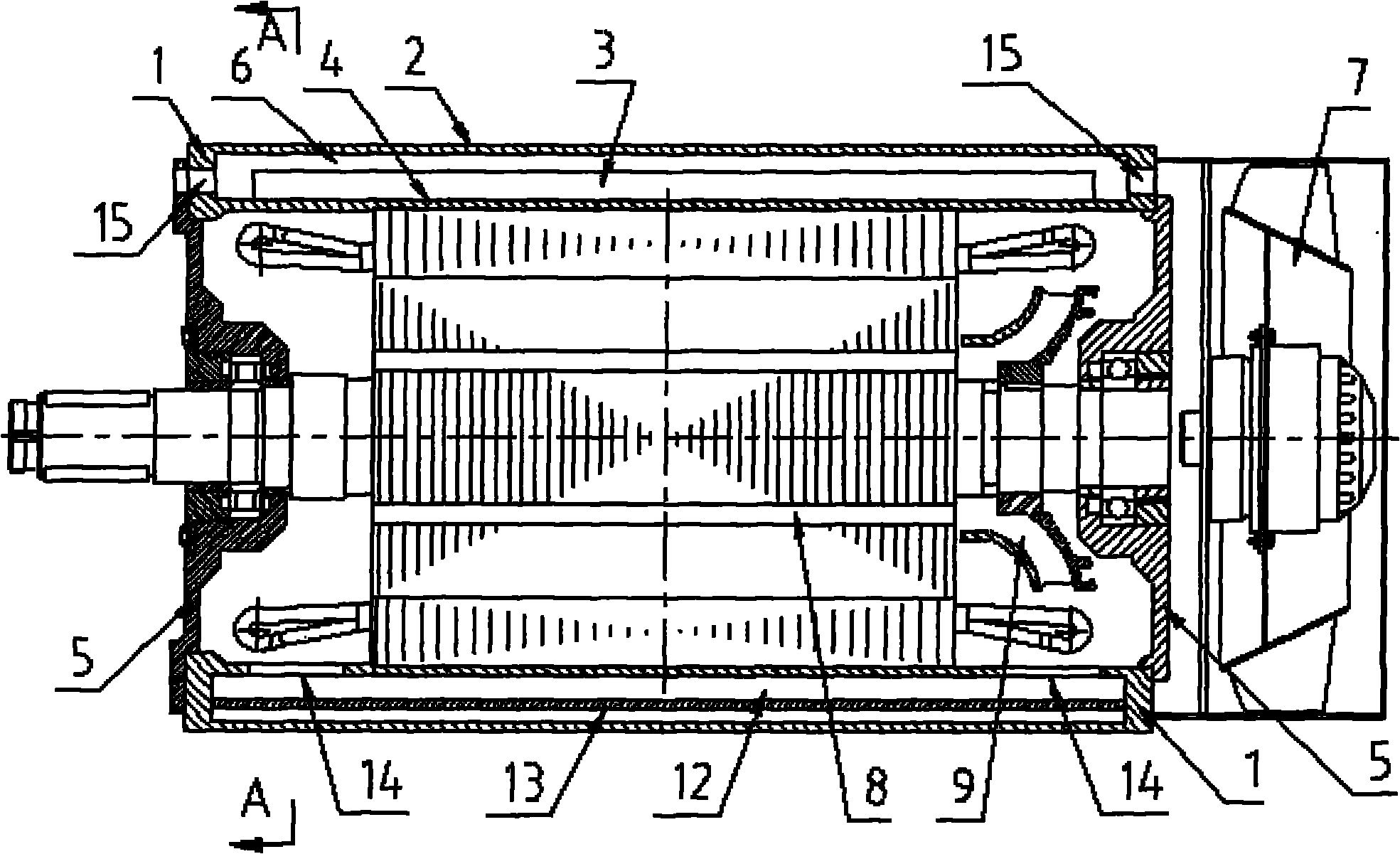

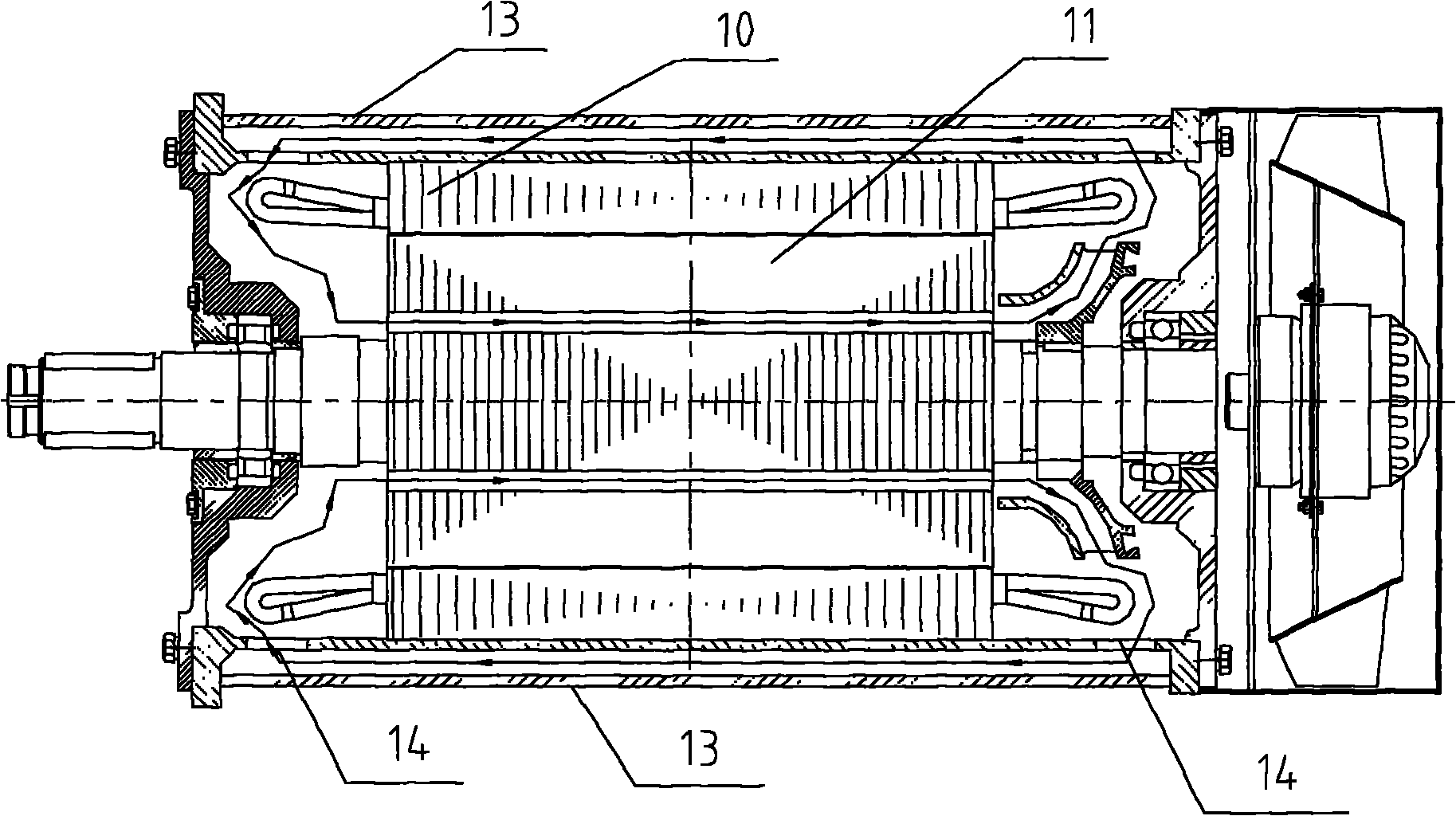

[0022] A motor with a mixed-flow fan for internal and external air circulation, including a casing, an end cover 5, an internal cooling system, and a rotor 11. The casing includes two flanges 1 and a frame shell 4. The surface of the frame shell 4 is axially two A pair of air holes 14 are opened at the end, an internal centrifugal fan 9 is provided on the shaft of the non-drive end of the rotor 11, a rotor air passage 8 is opened inside the iron core of the rotor 11, a mixed-flow forced cooling fan 7 is connected to the non-drive end of the motor, and the casing The base shell 4 is provided with U-shaped channel steel 13, and the U-shaped channel steel 13 is airtightly covered on the pair of air holes 14 opened in the axial direction on the surface of the machine base shell 4 to form the internal air duct 12 of the shell; There is a windshield 2, and the windshield 2 covers the U-shaped channel steel 13 and is welded between the two flanges 1 of the casing and the frame shell 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com