Coordinated control system (CCS) of large-size circulating fluidized bed boiler (CFBB) unit

A technology of coordinated control system and circulating fluidized bed, applied in fluidized bed combustion equipment, comprehensive factory control, comprehensive factory control, etc., can solve the problems of difficult automatic adjustment, many control variables, and many disturbances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

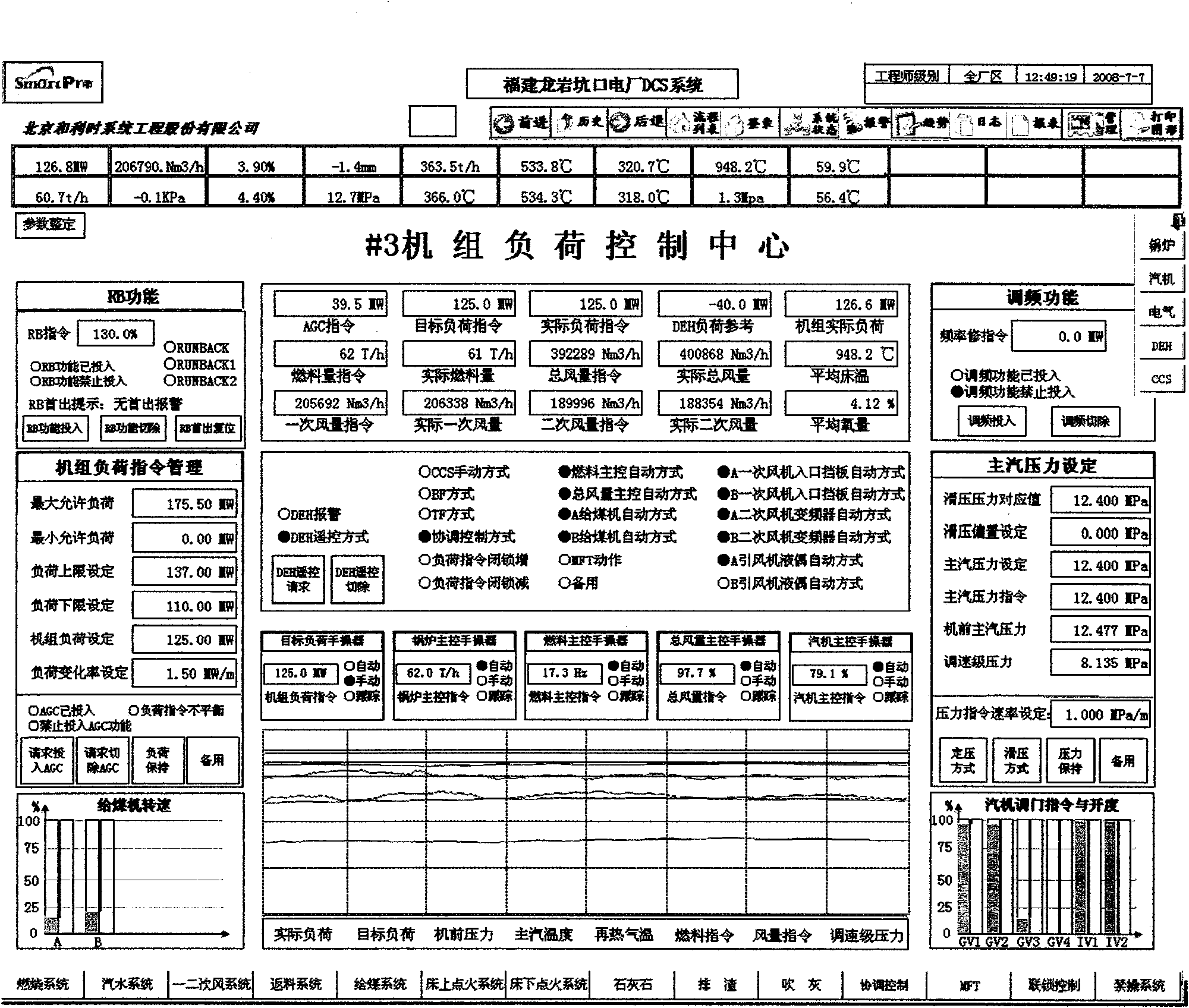

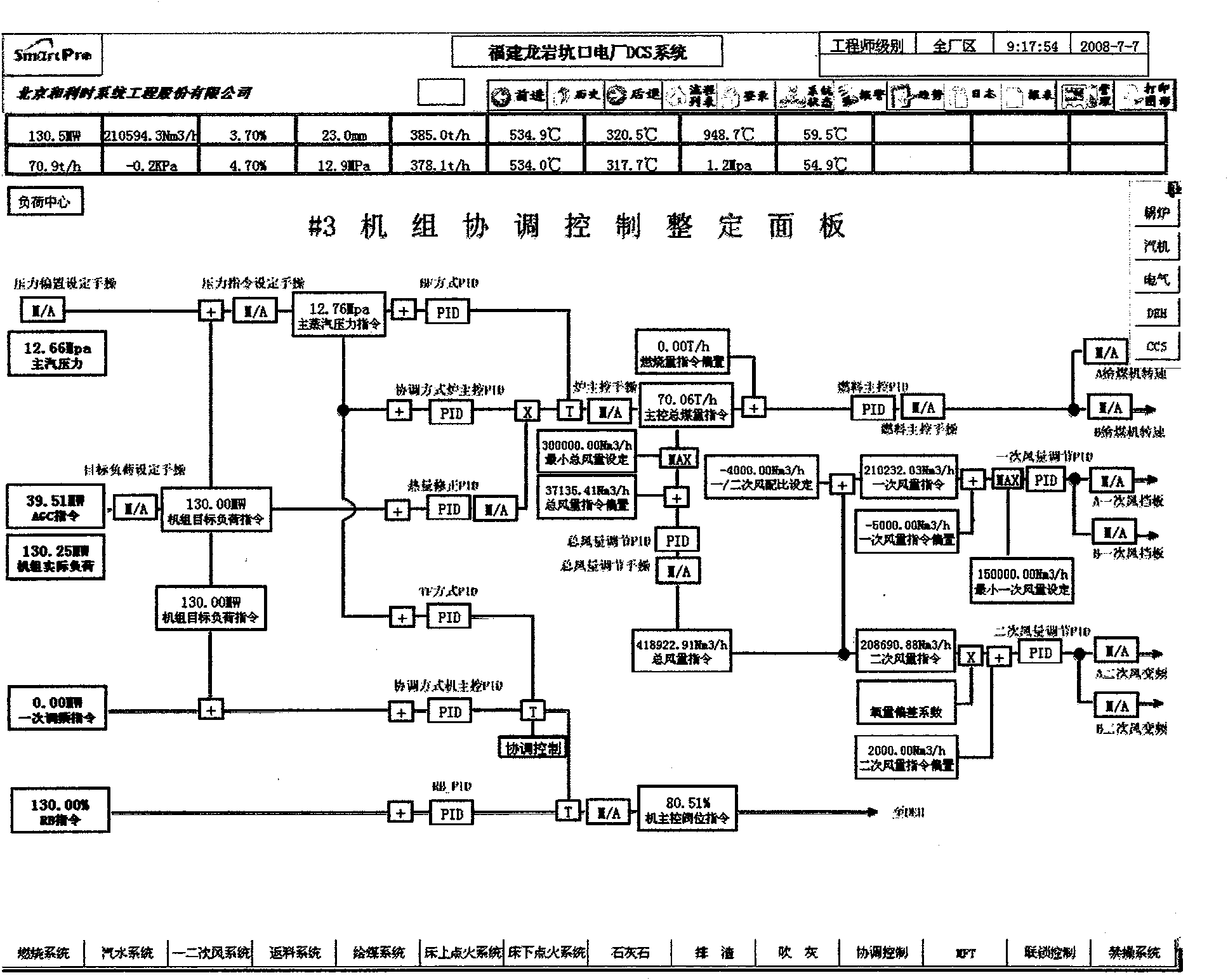

[0033] A large-scale circulating fluidized bed boiler (CFBB) unit coordination control system (CCS), is made up of computer algorithm implementation logic and human-machine interface (HMI); described computer algorithm implementation logic mainly CCS adjustment system and MCS adjustment system, According to the input parameters, it performs data processing and executes corresponding logic operations, and outputs machine furnace coordinated control commands to each closed-loop control system of the distributed control system (DCS); the HMI provides operators with instructions for lower-level control equipment The interactive man-machine interface consists of two parts: CCS operation control panel and parameter setting panel.

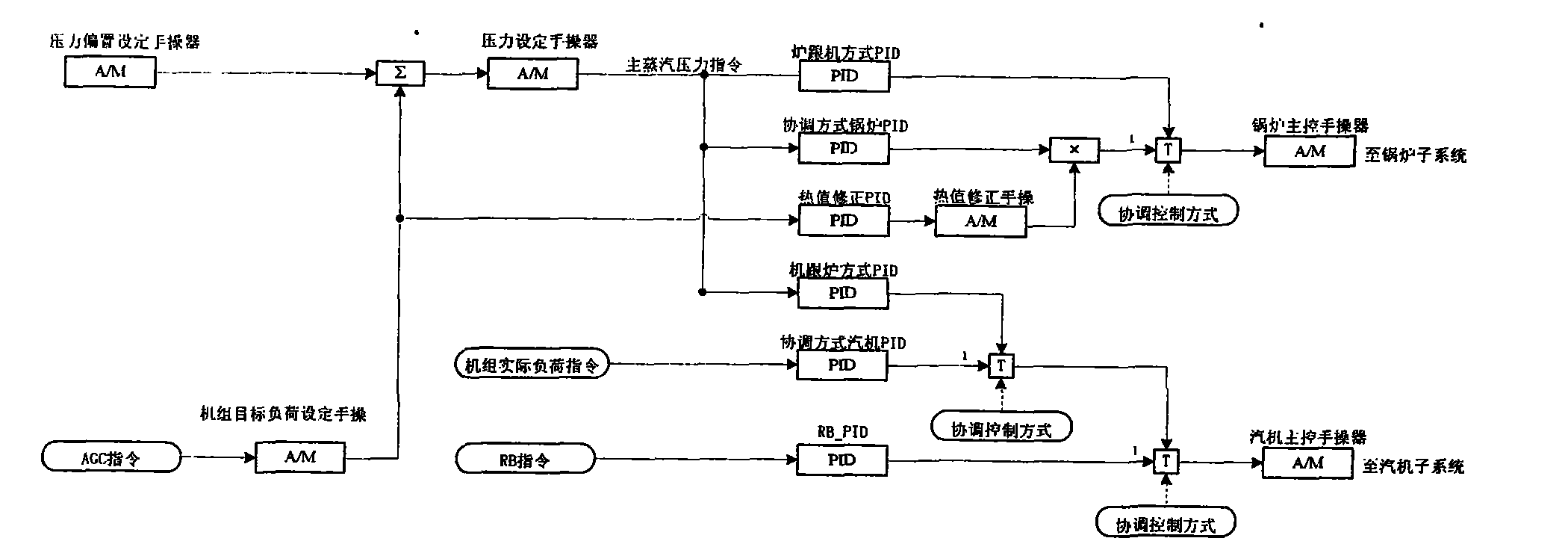

[0034] attached figure 1 It is a block diagram of the CCS regulation system flow chart designed in combination with the characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com