Water faucet

A faucet and water flow technology, which is applied in the field of faucets, can solve the problems of product wall thickness and unevenness, and achieve the effects of saving processing time, solving unfulfilling and unevenness, and saving processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention provides a faucet.

[0018] In order to make the technical solution of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

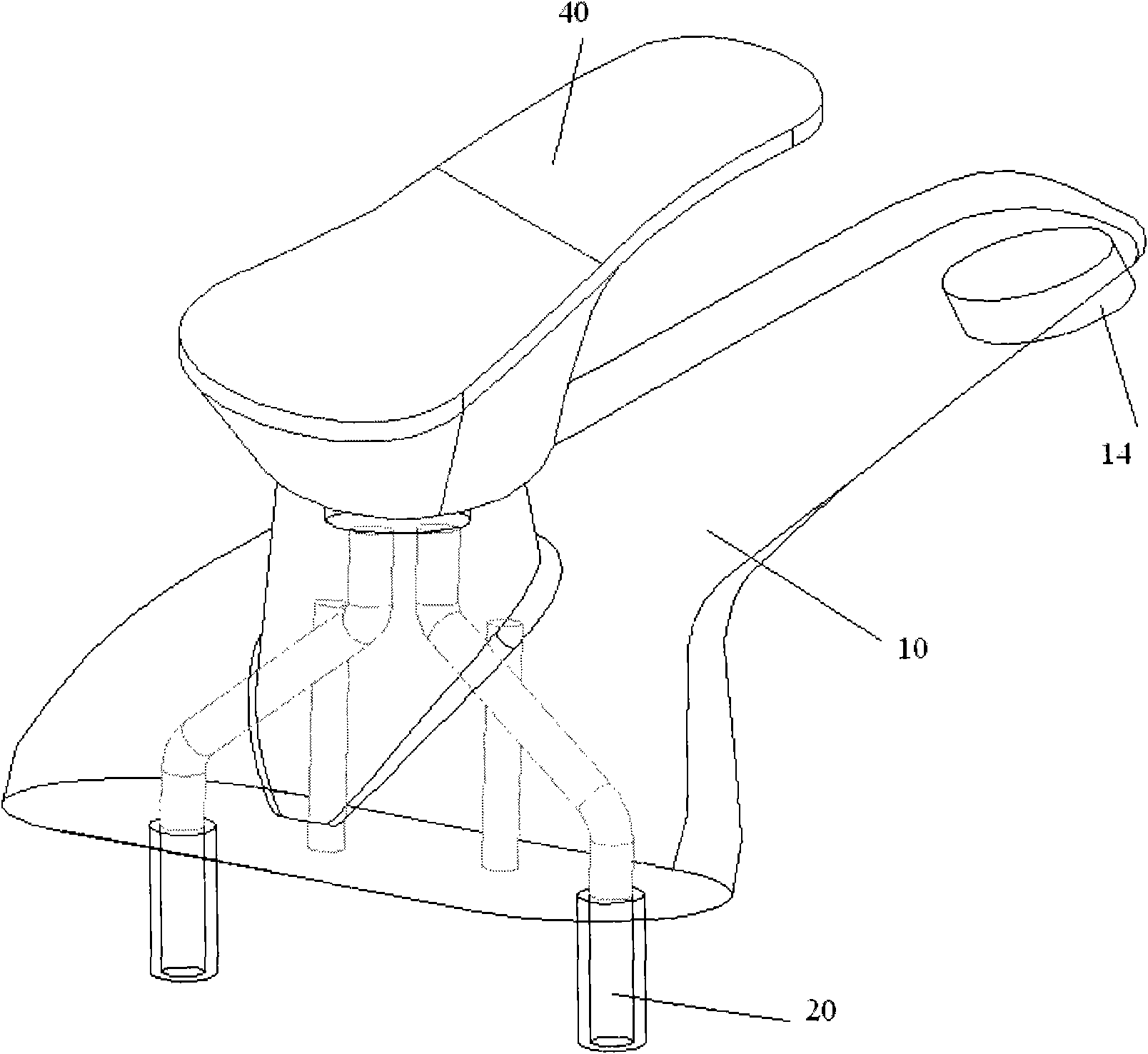

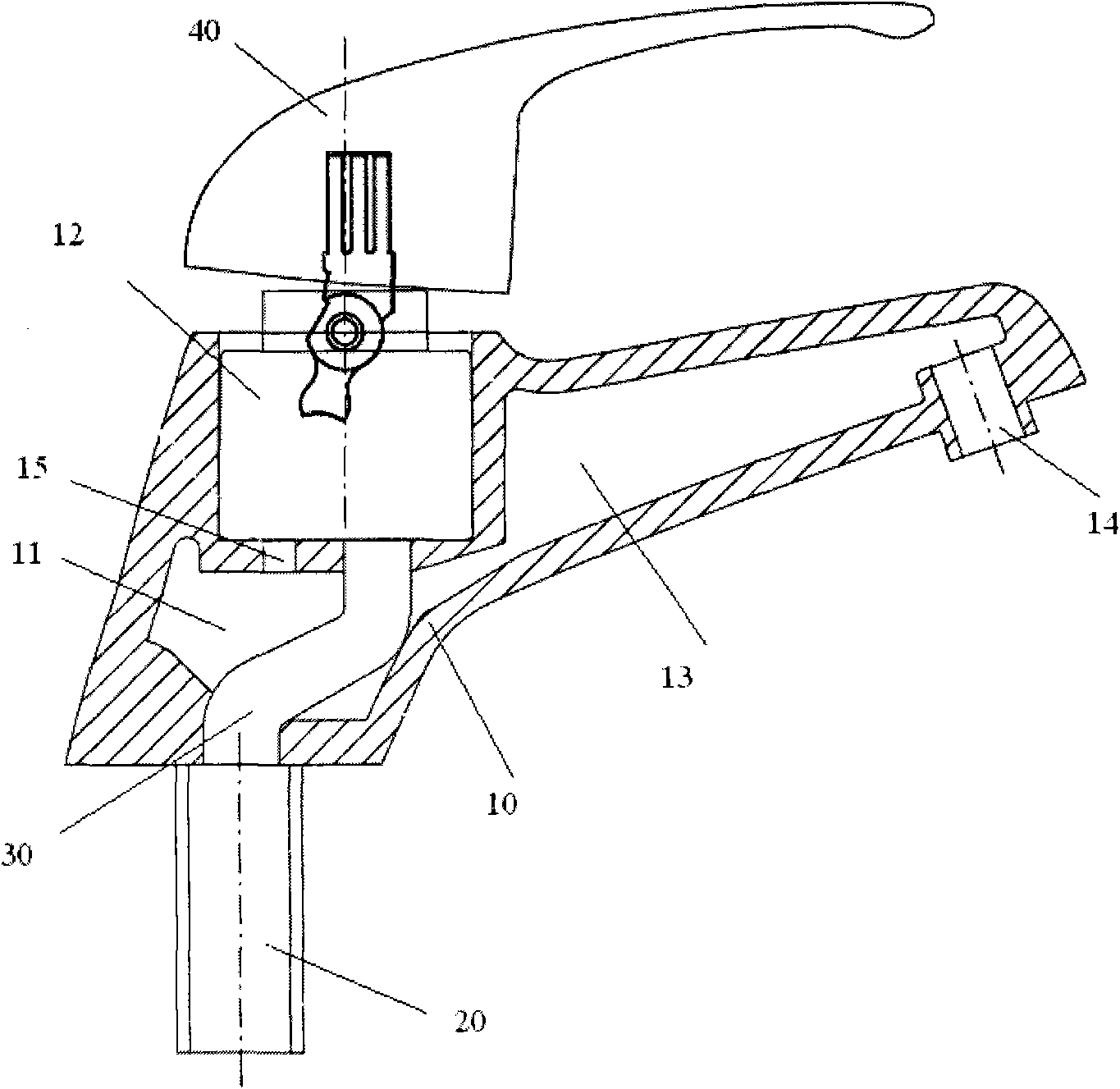

[0019] see figure 1 , is a three-dimensional schematic view of the faucet of the present invention.

[0020] The faucet includes a body 10 . A water inlet hole (not numbered) is provided below the body 10 to connect to a water inlet pipe 20 for water intake, wherein the water inlet pipe 20 includes hot water pipes and cold water pipes installed on the left and right sides of the body 10 . An on-off valve 40 for controlling water flow in and out is installed above the body 10 . The on-off valve 40 includes a handle, which is lifted upwards to one side, and the faucet can be connected to cold water, and the handle is lifted upwards to the other side, to be connected to hot water. The on-off valve 40 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com