Integrally-assembled buttressed retaining wall and construction method thereof

A retaining wall and buttress-type technology, which is applied in the field of assembling integral buttress-type retaining wall structures, can solve the problems of a large amount of labor and slow construction speed, and achieve the effects of low project cost, fast construction speed and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

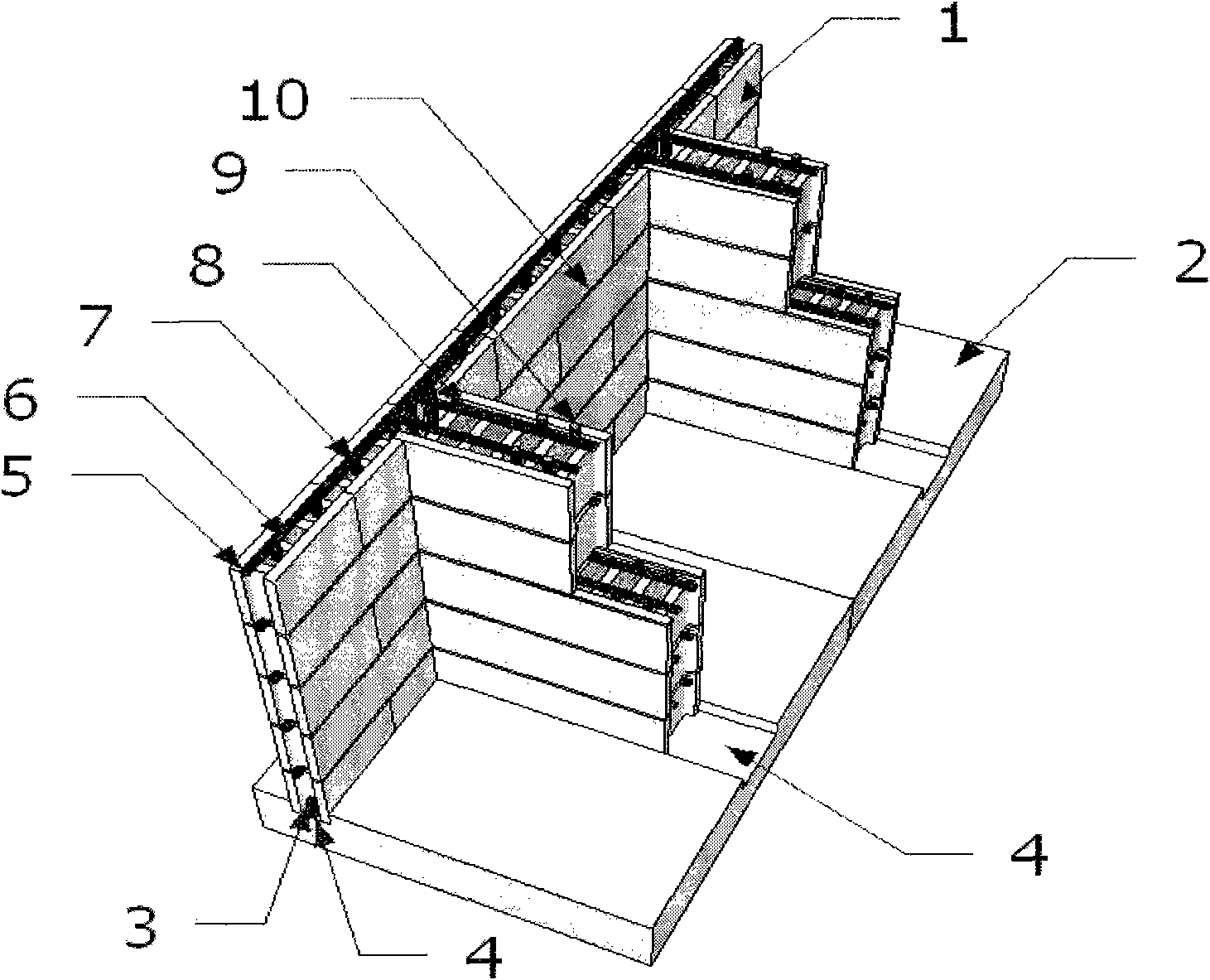

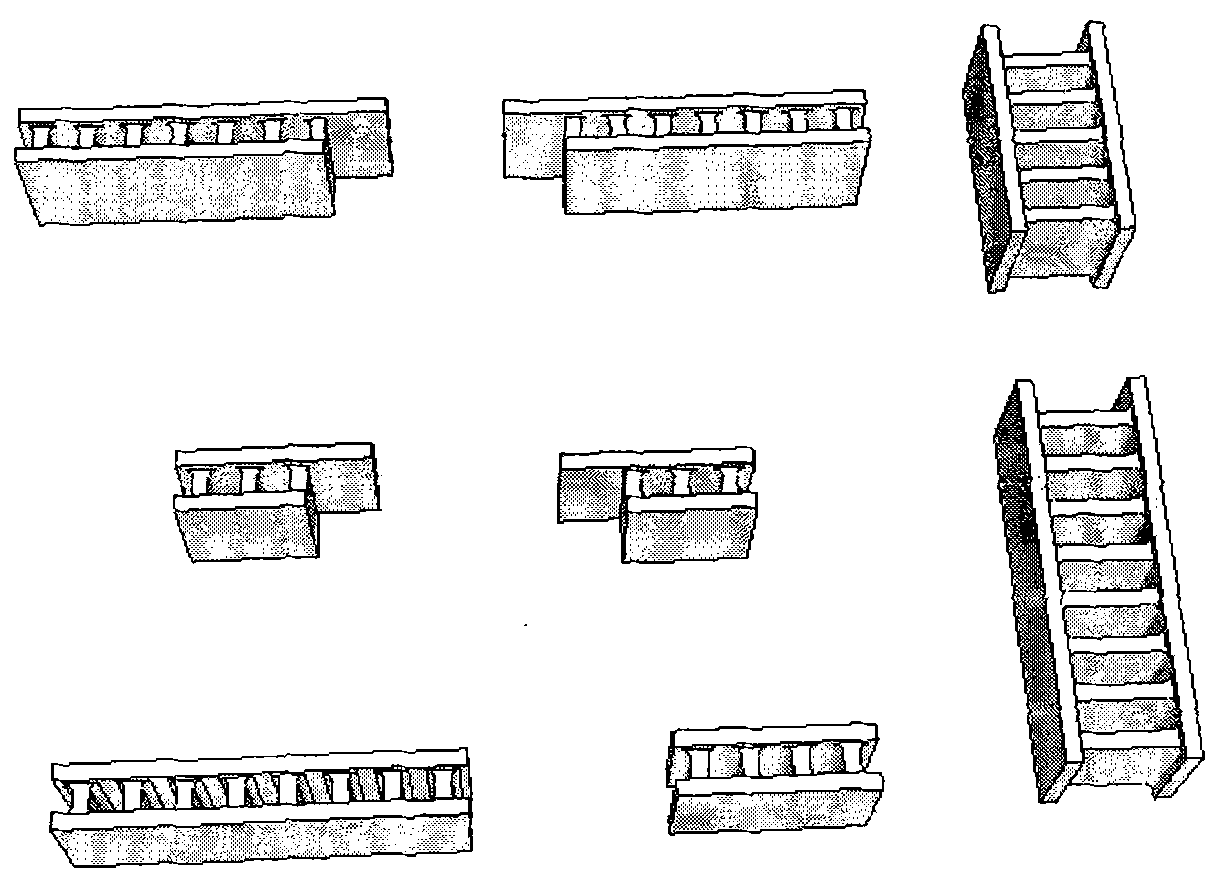

[0023] see figure 1 , an assembled monolithic buttress-type retaining wall, comprising a precast concrete hollow wall panel 1 and a prefabricated reinforced concrete bottom slab 2 with vertically lapped steel bars 3 and grooves, when assembling, the precast concrete of the lowest piece is hollow The wall panel 1 is stuck in the groove 4 and the vertical overlapping steel bar 3 is extended into the hole in the precast concrete hollow wall panel 1. In the horizontal groove of the prefabricated concrete hollow wall panel on the first floor, respectively place the horizontal stressed steel bar 5 and the L-shaped distributed steel bar 8, respectively insert the vertical stressed steel bar 7 and 9 in the holes of the wall panel and the buttress, and finally pour the hole-filled concrete An assembled integral buttress retaining wall is formed.

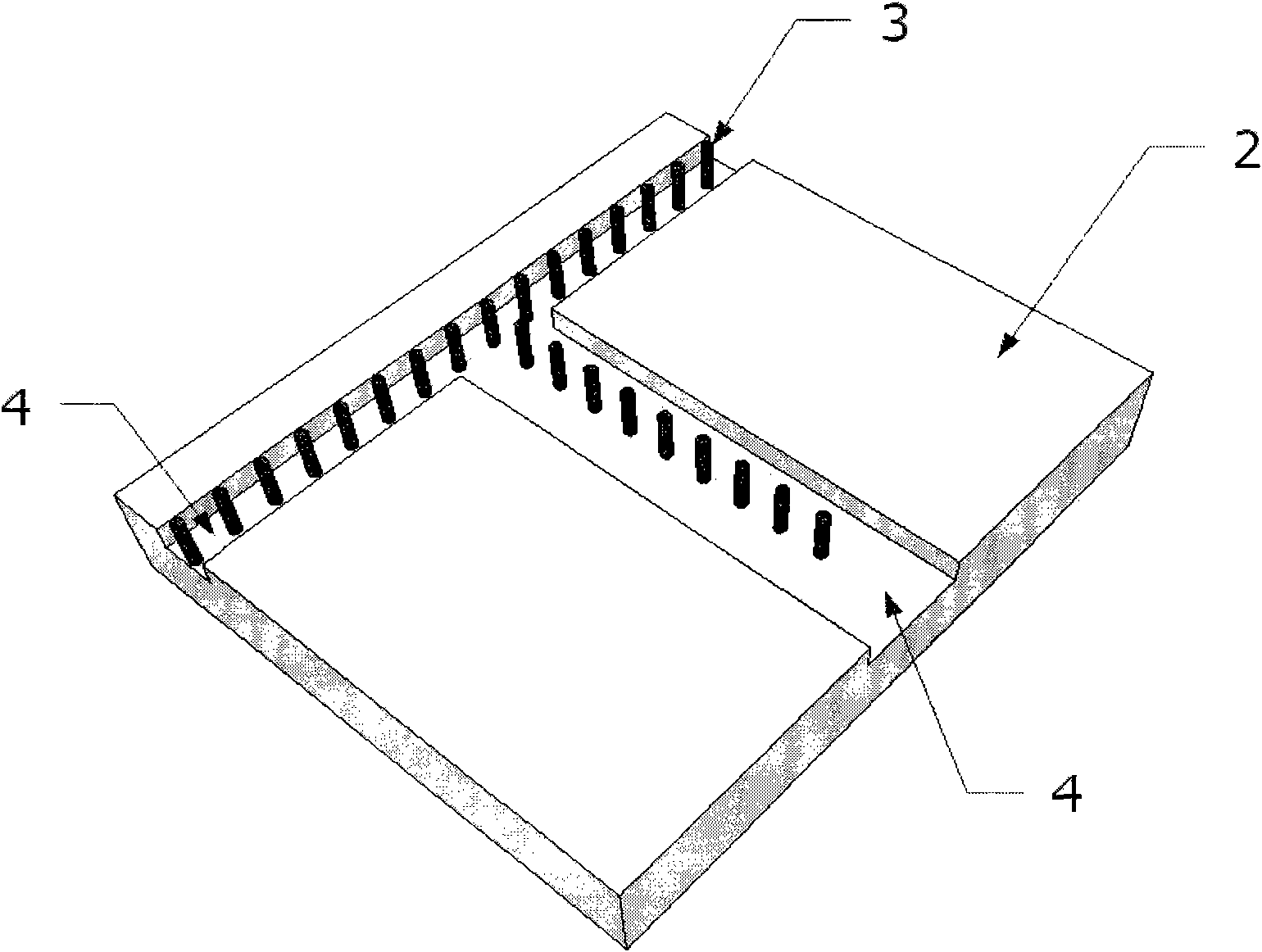

[0024] see figure 2 , the prefabricated reinforced concrete bottom slab 2 is left with vertically lapped steel bars 3 and grooves 4, the ...

Embodiment 2

[0028] Construction of assembled integral buttress retaining walls:

[0029] (a) Preparatory work: including the prefabrication preparation work of the concrete hollow wall panel 1 and the reinforced concrete floor 2 and the preparation work on the construction site. The prefabrication preparation work is carried out in the prefabrication factory. According to the design drawings, the concrete hollow wall panels 1 or hollow blocks and the reinforced concrete bottom slab 2 with vertically lapped reinforcement bars 3 and grooves 4 are prefabricated. Before the official construction on site, the site should be cleaned up, and materials (cement, sand, pebbles, graded crushed stones) should be piled up. In addition, the drainage work of the construction site should be done in advance. At the two adjacent prefabricated reinforced concrete bottom slabs 2 , the lowest prefabricated concrete hollow wall panel 1 is stuck in the grooves of the two prefabricated reinforced concrete bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com