Method for separating and purifying rhamnolipid

A rhamnolipid, separation and purification technology, applied in the field of separation and purification, can solve the problems of multiple extractions, difficulty in separation, and unavoidable crossover of components, and achieve the effects of good repeatability, low purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

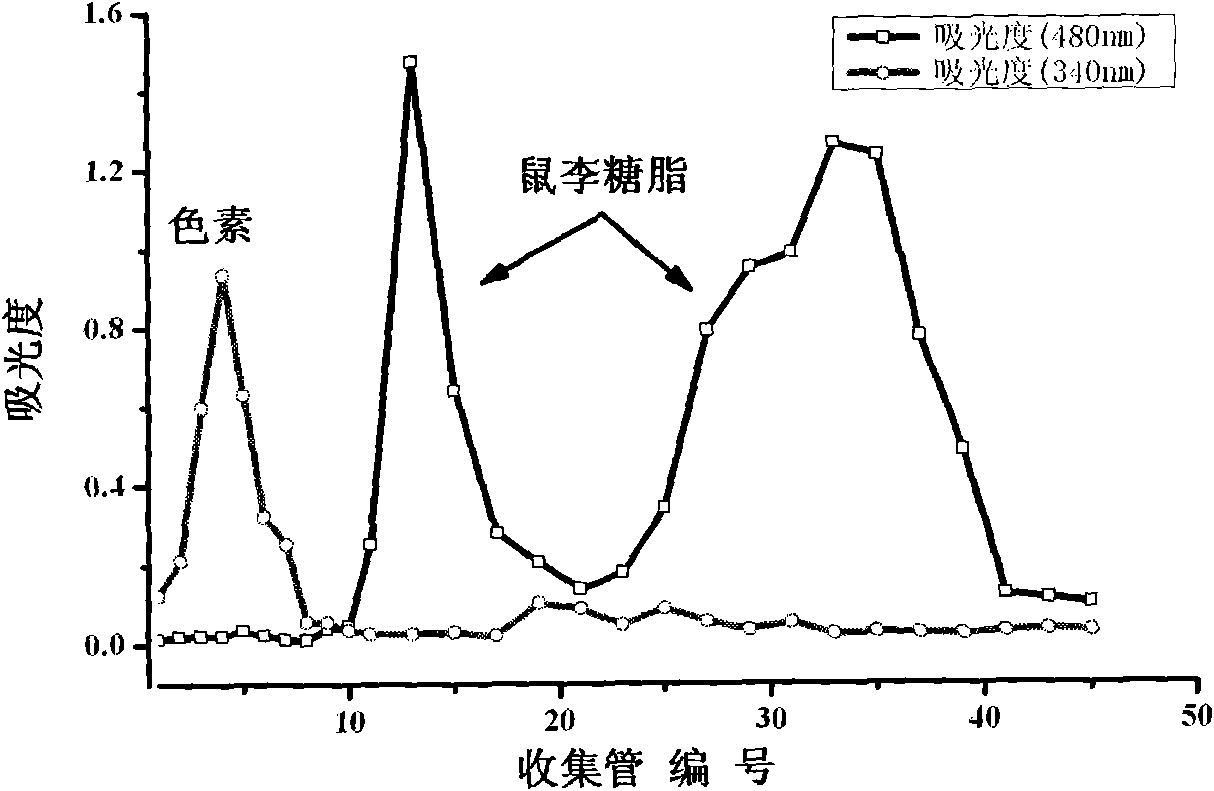

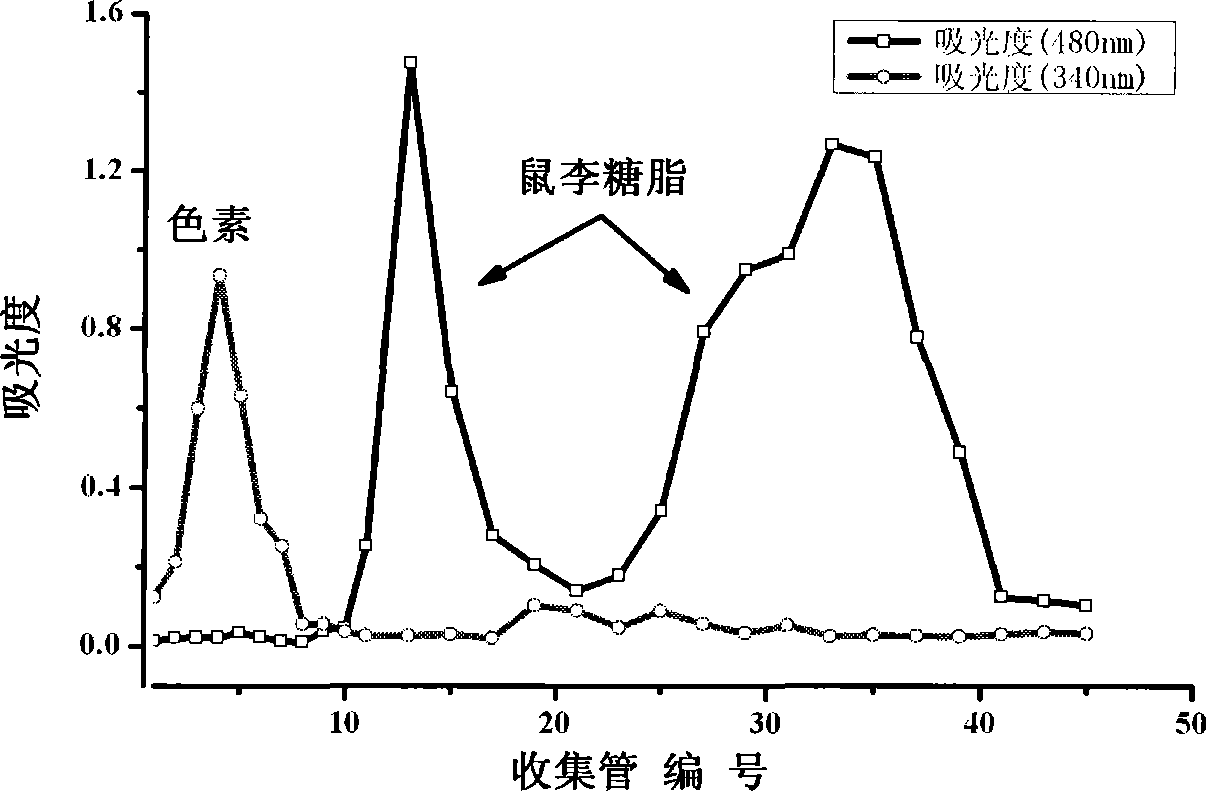

Image

Examples

Embodiment 1

[0024] A method for separating and purifying rhamnolipids, the method comprising the following steps:

[0025] (1) Centrifuge the rhamnolipid-containing fermentation broth at 5000r / min for 30min, adjust the pH of the obtained supernatant to 2.0 with 6mol / L hydrochloric acid, leave it overnight at 4°C and centrifuge at 5000r / min for 30min, collect the precipitate Utilize diethyl ether to extract, after combining organic phase, blow-dry and freeze-dry to obtain rhamnolipid crude product 0.5g, adopt the mixed organic solvent obtained by mixing chloroform and methanol at a volume ratio of 25:1, take the mixed organic solvent 1.0 mL dissolves the rhamnolipid crude product to obtain a dissolved sample;

[0026] (2) Add the dissolved sample obtained in step (1) to a 200-mesh silica gel column 200mL of the first organic solvent obtained by mixing chloroform and methanol at a volume ratio of 25:1 was added to a silica gel column to elute the dissolved sample, and then chloroform and ...

Embodiment 2

[0030] A method for separating and purifying rhamnolipids, the method comprising the following steps:

[0031] (1) Centrifuge the rhamnolipid-containing fermentation broth at 5000r / min for 30min, adjust the pH of the obtained supernatant to 1.5 with 6mol / L hydrochloric acid, leave it overnight at 4°C and centrifuge at 5000r / min for 30min, collect the precipitate Utilize ethyl ether to extract, combine the organic phases and then blow dry and dry to obtain 6.0 g of rhamnolipid crude product, adopt the mixed organic solvent obtained by mixing chloroform and methanol at a volume ratio of 20:1, and take 12.0 mL of the mixed organic solvent Dissolving the rhamnolipid crude product to obtain a dissolved sample, the amount of the dissolved sample is 2% of the column volume of the silica gel column;

[0032] (2) Add the dissolved sample obtained in step (1) to a 300-mesh silica gel column, the diameter of the silica gel column is 3cm, and the length and diameter ratio of the silica ge...

Embodiment 3

[0036] A method for separating and purifying rhamnolipids, the method comprising the following steps:

[0037] (1) Centrifuge the rhamnolipid-containing fermentation broth at 5000r / min for 30min, adjust the pH of the obtained supernatant to 1.8 with 6mol / L hydrochloric acid, leave it overnight at 4°C and centrifuge at 5000r / min for 30min, collect the precipitate Utilize ethyl ether to extract, after merging the organic phases, blow-dry and freeze-dry to obtain 2.0Kg of rhamnolipid crude product, adopt the mixed organic solvent obtained by mixing chloroform and methanol in a volume ratio of 30:1, take the mixed organic solvent 4.0 L dissolves the rhamnolipid crude product to obtain a dissolved sample, and the amount of dissolved sample is 2% of the column volume of the silica gel column;

[0038] (2) Add the dissolved sample obtained in step (1) to a 300-mesh silica gel column. The diameter of the silica gel column is 30 cm, and the aspect ratio is 10:1. Chloroform and methanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com