Reduction method for biological sludge

A biological sludge and sludge technology, which is applied in biological sludge treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of difficulty in breaking microbial cell walls, high energy consumption, and high cost, and reduce sludge production The effect of increasing the amount, increasing the contact area, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

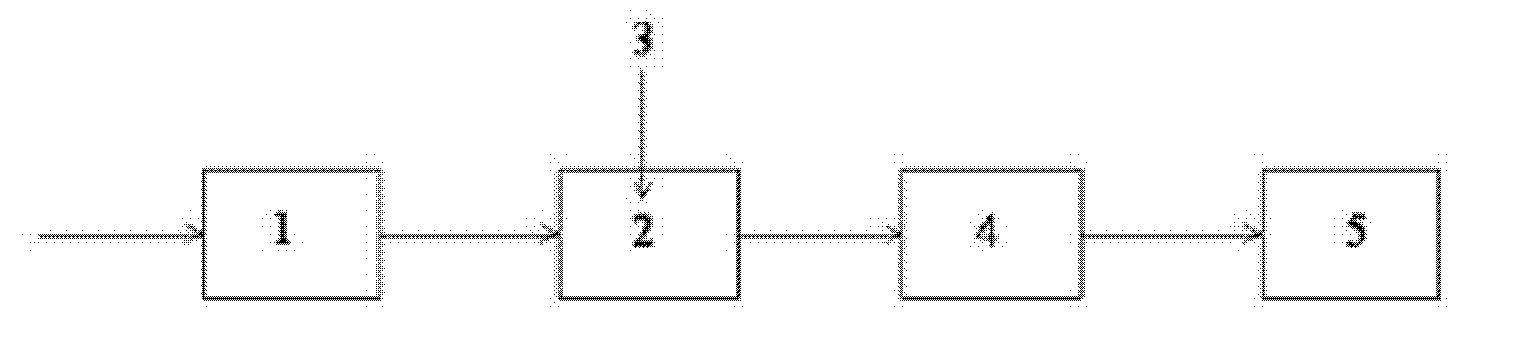

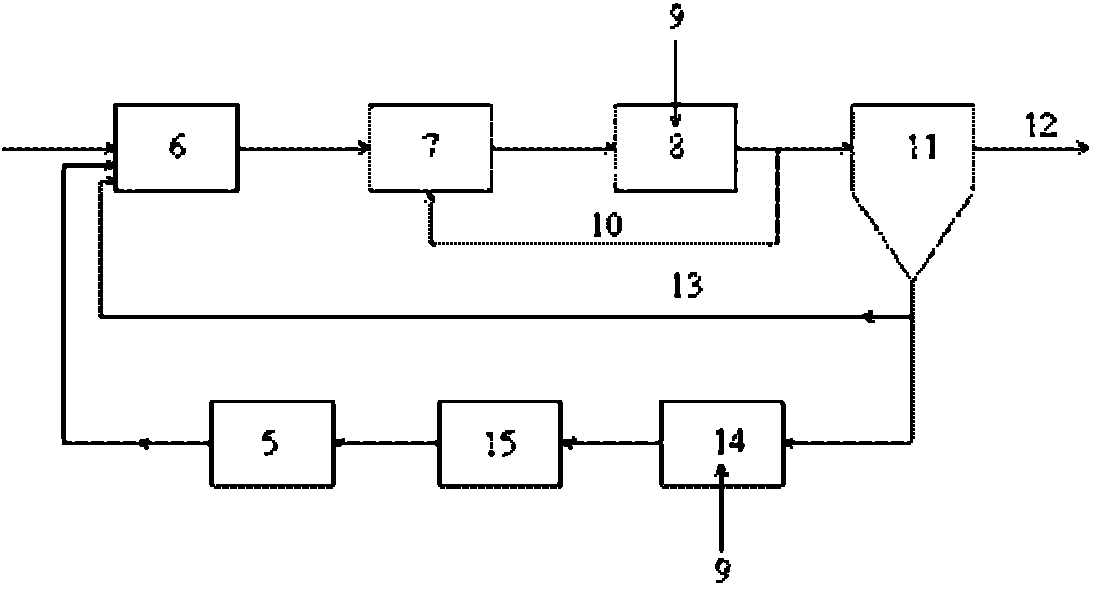

Method used

Image

Examples

Embodiment 1

[0022] The remaining sludge discharged from the final sedimentation tank is heated to a temperature of 100°C, and the non-ionic surfactant TW-80 is added first, and the dosage is 10 mg / l, which is left for 30 minutes, and then Ca(OH) is added. 2 The pH value of the liquid was adjusted to 9, and it was kept at 100°C for 15 minutes. After the above treatment, the SCOD / TCOD value of the sludge was measured to be 0.94, which was close to completely breaking the wall.

Embodiment 2

[0024] Add the anionic surfactant sodium dodecylbenzoate to the remaining sludge discharged from the final sedimentation tank, the dosage is 500mg / l, let it stand for 15 minutes, then add KOH liquid to adjust the pH value to 10, and send it to the ultrasonic reaction device at 1.34W / cm 2 Sludge wall breaking was carried out for 3 minutes under the sound energy density. The SCOD value obtained after the completion of wall breaking was 3126mg / L, while the SCOD value obtained by ultrasonication for 10 minutes was 3216mg / L when the pH value was 10 but no surfactant was added, and the two remained basically the same. Under the condition of achieving the same lysis effect, ultrasonic is costly and produces noise pollution, while adding surfactant is more economical and convenient.

Embodiment 3

[0026] Send the sludge discharged from the final sedimentation tank to the sludge pretreatment tank for aeration, control the dissolved oxygen at about 4.5mg / l, and aerate for 15 minutes. Then add cationic surfactant benzalkonium chloride, the dosage is 200mg / l, and the standing time is 30 minutes, and then add NaOH liquid to adjust the pH value to 11. Results Compared with the system without aeration, under the condition of the same wall-breaking effect, the amount of alkali is reduced by 35%, and the operating cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com