Packaging method of material containing liquid material or volatile material

A liquid material and packaging method technology, applied in packaging, packaged food, multiple packages, etc., can solve the problems of uneven effect of small package products, unstable effect of materials, and difficulty in mixing uniformly, so as to avoid performance changes, Effect of reducing exposure time and saving production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A deoxidizing antistaling agent, which contains non-volatile materials: iron powder, diatomaceous earth, salt and activated carbon; liquid materials: water.

[0023] The packing method of above-mentioned deoxidation antistaling agent, its steps are: (1) weigh the non-volatile material of described deoxidation antistaling agent, i.e. iron powder, diatomaceous earth, salt and gac, mix uniformly; Measure liquid material, i.e. water ; (2) packing non-volatile materials into packaging bags; (3) mixing liquid materials into packaging bags with the non-volatile materials; (4) sealing the packaging bags.

Embodiment 2

[0025] In order to further illustrate and describe the material packaging method of the present invention containing liquid materials or volatile materials, the present invention also provides a material packaging machine with a liquid injection device, and its specific structure is as follows:

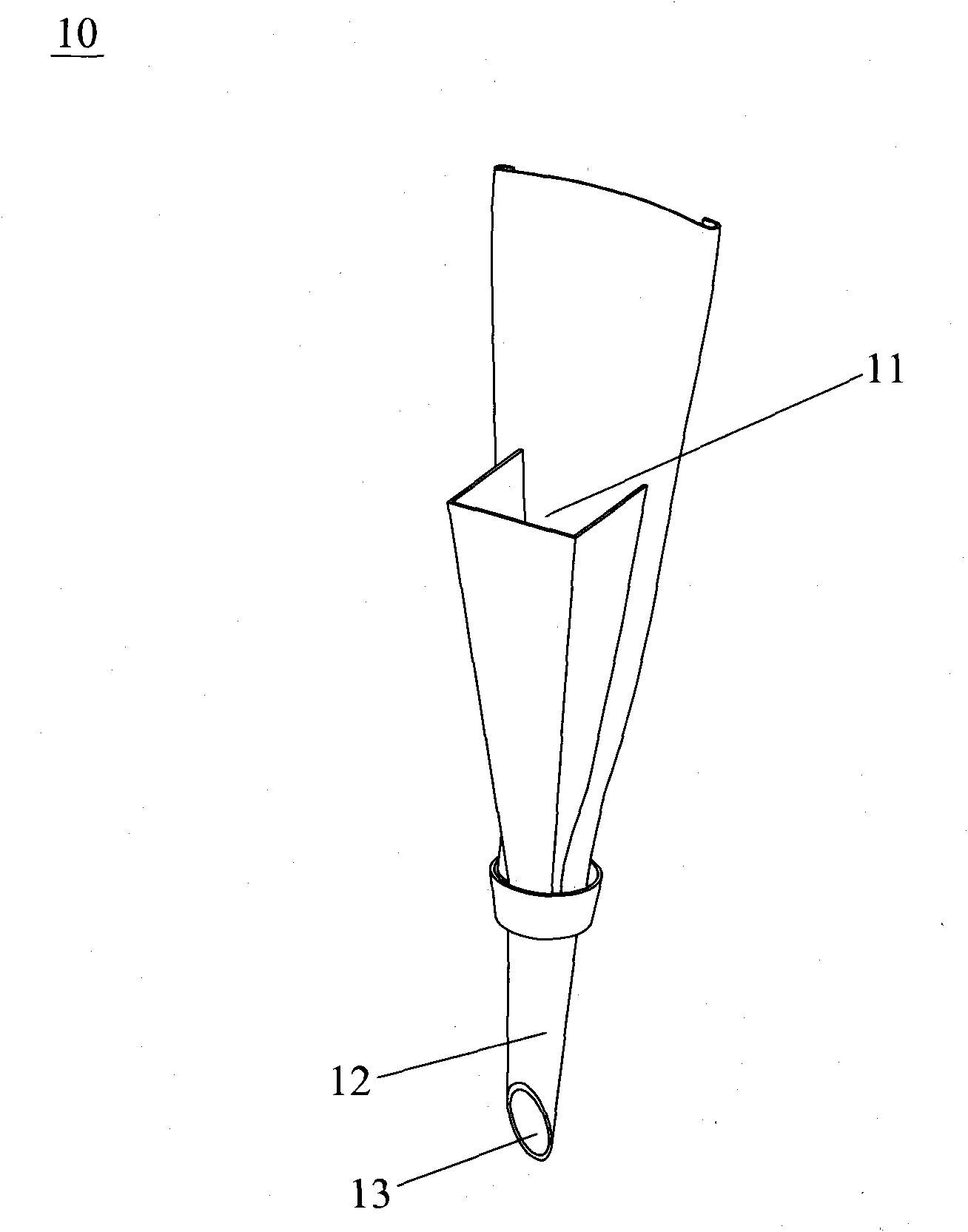

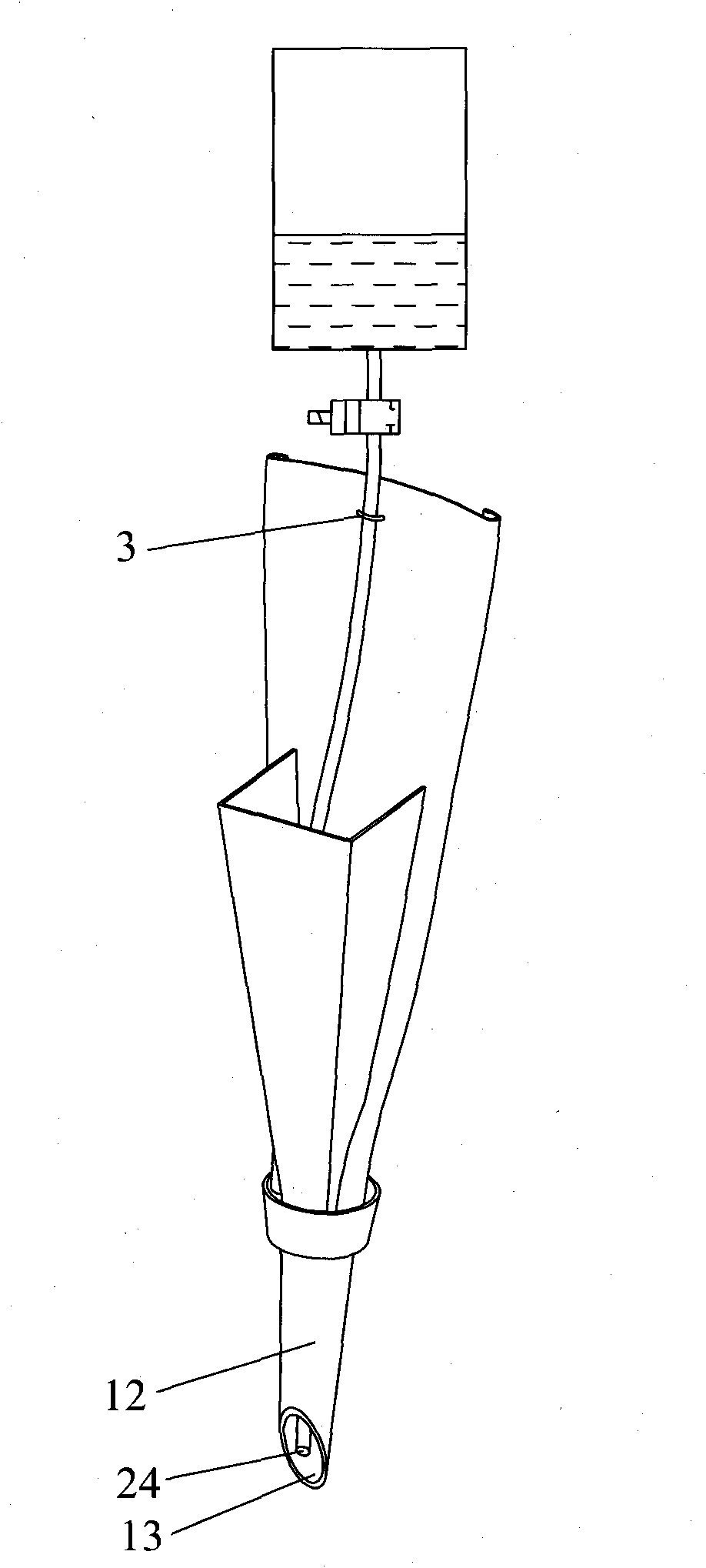

[0026] refer to figure 1 , a material packaging machine with a liquid injection device, has a feeding cavity 10 and a feeding nozzle 13. The feeding chamber 10 has a material tank 11 for containing materials, a feeding tube 12 located below the material tank 11 and communicating with the material tank, and a feeding nozzle 13 located at the end of the feeding tube 12 .

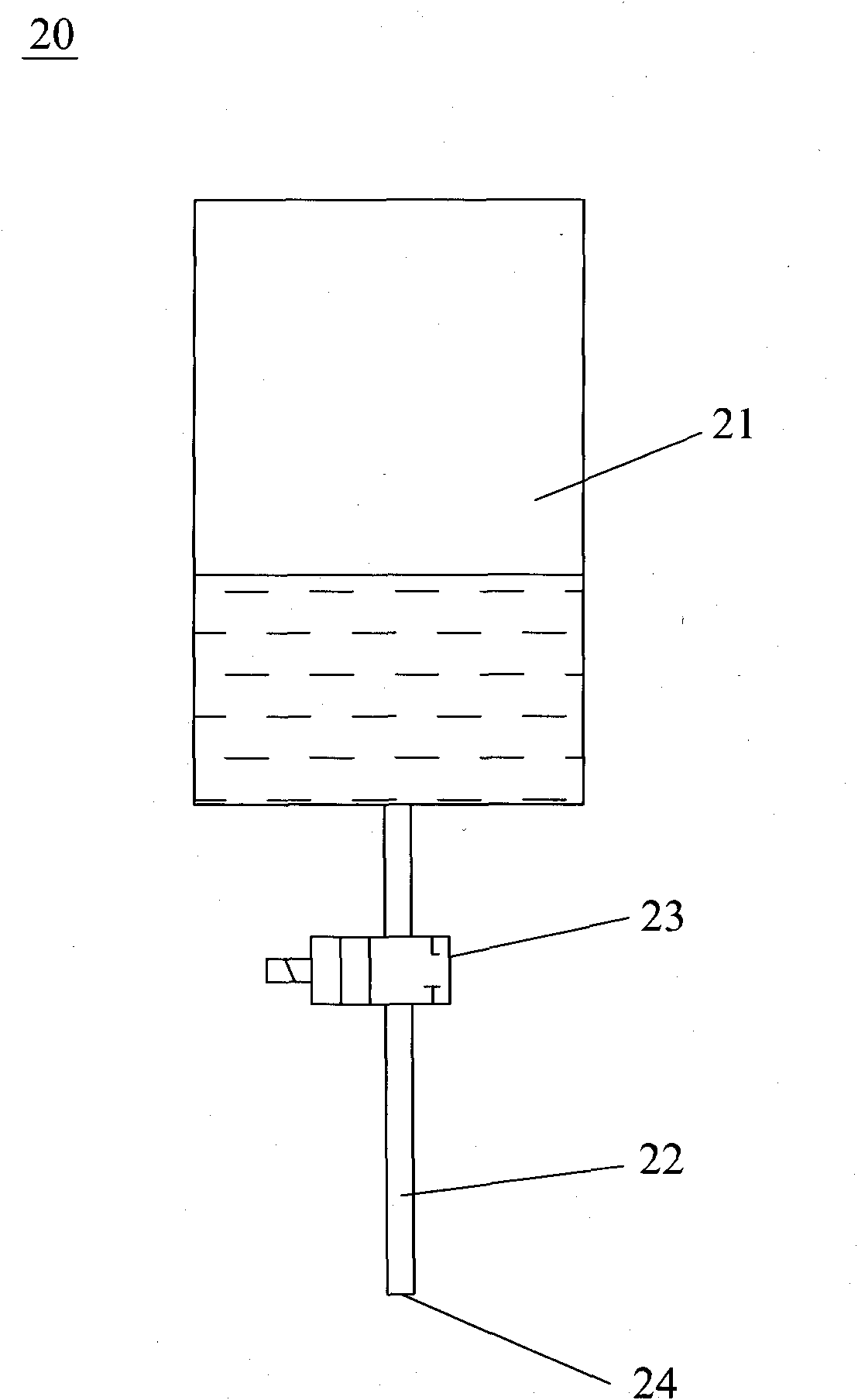

[0027] refer to figure 2 , figure 2 A liquid injection device 20 of a material packaging machine with a liquid injection device according to the present invention is shown. The liquid injection device 20 has a liquid storage tank 21 and a pipeline 22 communicating with the lower part of the liquid storage tank 21...

Embodiment 3

[0037] A double-effect fresh-keeping agent: it contains non-volatile materials: iron powder, diatomaceous earth, salt, activated carbon and liquid materials: water and edible alcohol.

[0038] The packaging method of the above-mentioned double-effect preservative includes weighing the non-volatile materials: iron powder, diatomaceous earth, salt and activated carbon; measuring the liquid materials: water and edible alcohol; weighing the non-volatile materials: iron powder, Diatomaceous earth, salt, activated carbon are mixed evenly, placed in the material storage device of the above-mentioned material packaging machine, the liquid material: water and edible alcohol are mixed evenly, placed in the liquid storage tank 21 of the above-mentioned material packaging machine, and the material packaging machine is started , when the packaging material moves to the feeding nozzle 13 and wraps the feeding nozzle 13, the sealing device seals the side and the bottom of the packaging materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com