Method and device for online cleaning filtering cloth for filtering sodium aluminate slurry

A technology of sodium aluminate and filter cloth, applied in the direction of moving filter element filter, filtration separation, separation method, etc., can solve the problems of increasing secondary reaction opportunities, long liquid-solid contact time, and damage to red mud utilization, etc. The effect of reducing the amount of material operation, eliminating the phenomenon of hardening, and restoring the filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Taking the dissolution of alumina from soda lime sintered clinker as an example, the sodium aluminate in the clinker is dissolved with water or dilute alkali solution to form a sodium aluminate slurry mixed with sodium aluminate and insoluble minerals.

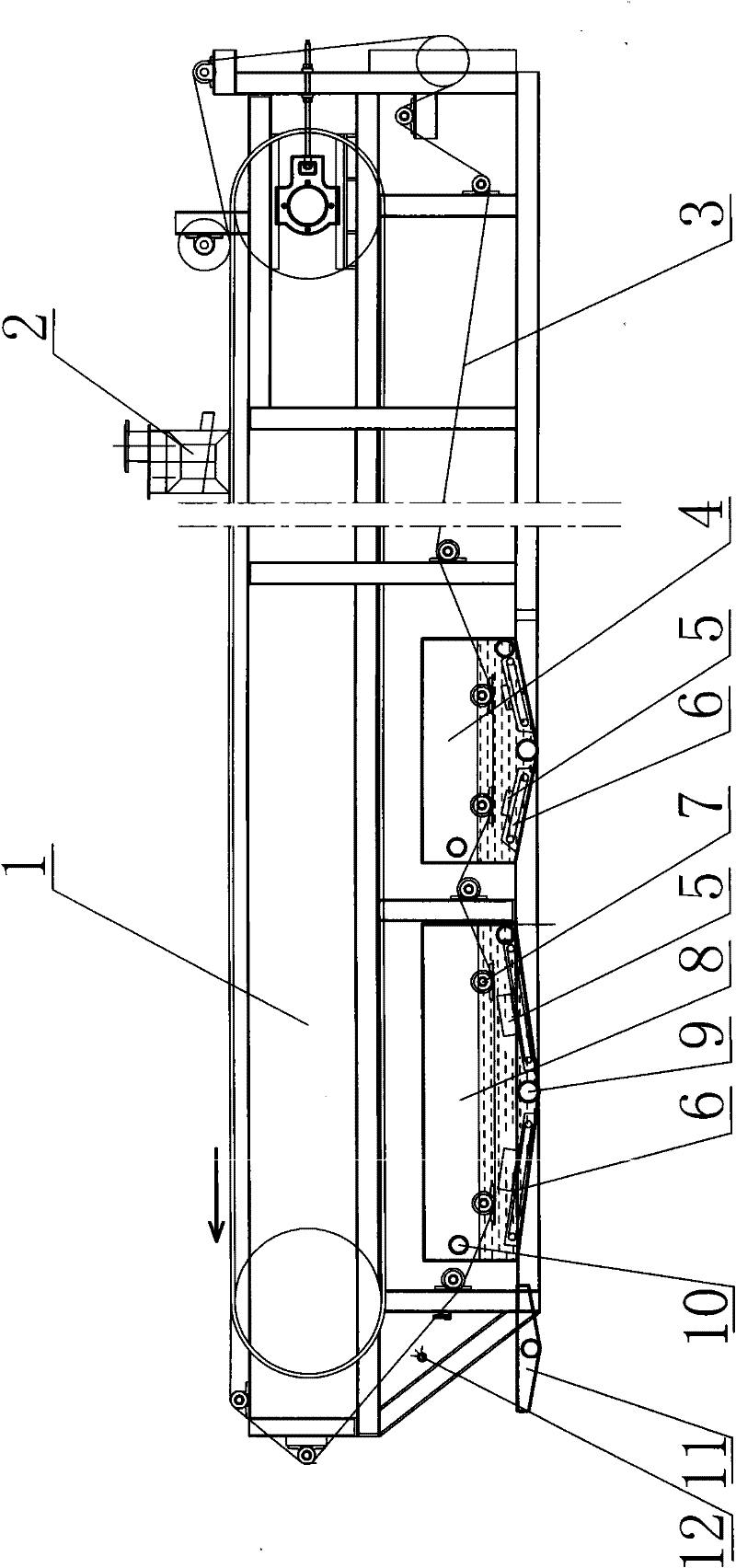

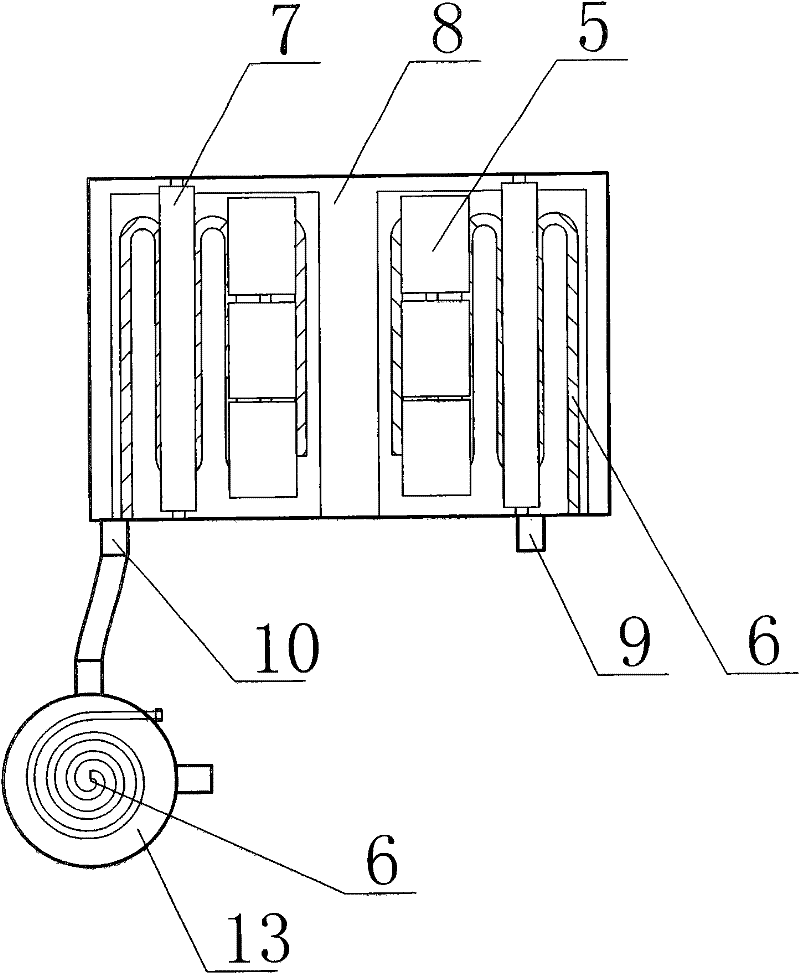

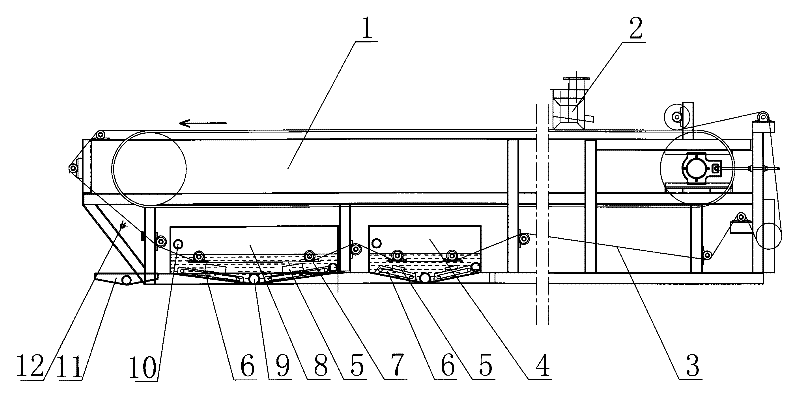

[0026] Such as figure 1 As shown, the sodium aluminate slurry is pumped into the distributor 2 on the horizontal belt vacuum filter 1, and the slurry is evenly spread on the moving filter cloth 3. The filter cloth 3 moves at a constant speed, the sodium aluminate solution in the slurry is continuously pumped into the filtrate collection pan, and the filter cake on the filter cloth 3 is also continuously drained. During this process, a part of the sodium aluminate due to temperature Reduction and exposure to CO in the air 2 Gas, etc., are decomposed to form aluminum hydroxide, which precipitates crystals on the filter cloth and in the capillary channels of the filter cloth.

[0027] The filter cloth 3 runs to the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com