Glass article with improved chemical resistance

A technology of glass products and products, applied in the field of glass products, can solve the problems of limited effect and slowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 (according to the present invention)

[0048] A piece of transparent soda-lime float glass with a thickness of 4mm and a size of 20cmx20cm was washed with tap water, deionized water and isopropanol in sequence, and finally dried.

[0049] Hydrogen and oxygen are introduced into a spot burner to form a flame at the burner outlet. The surface of the pre-washed glass sheet was placed near the end of the flame. Will contain aluminum nitrate 9 hydrate Al (NO 3 ) 3 9H 2 A solution of O in methanol (aluminum / methanol weight dilution ratio = 1 / 80) was introduced into the flame. Nanoparticles of aluminum oxide are thus generated in the flame, which are then collected on the surface of the glass sheet preheated in a furnace at 650°C. In order to cover the entire surface of the glass sheet, the burner is moved in two spatial directions within the surface of the glass sheet. The burner head moves continuously at a fixed speed of 3 meters per minute in one of the...

Embodiment 2

[0056] Embodiment 2 (according to the present invention)

[0057] A piece of transparent soda-lime float glass with a thickness of 4mm and a size of 20cmx20cm was washed with tap water, deionized water and isopropanol in sequence, and finally dried.

[0058] A dry powder of aluminum oxide nanoparticles, such as that supplied by PlasmaChem, is deposited in a sprinkle manner on the surface of a pre-washed glass slide. The nanoparticles used have a particle size of 5-150 nm. Most of them are crystalline and the crystals belong to three different crystal systems: rhombohedral (α-Al 2 o 3 ), tetragonal system (β-Al 2 o 3 ) and cubic (γ-Al 2 o 3 ).

[0059] After the deposition of the nanoparticles, the glass sheet was heated in an oven at 900°C for one hour, followed by controlled cooling at a rate of up to 35°C per hour.

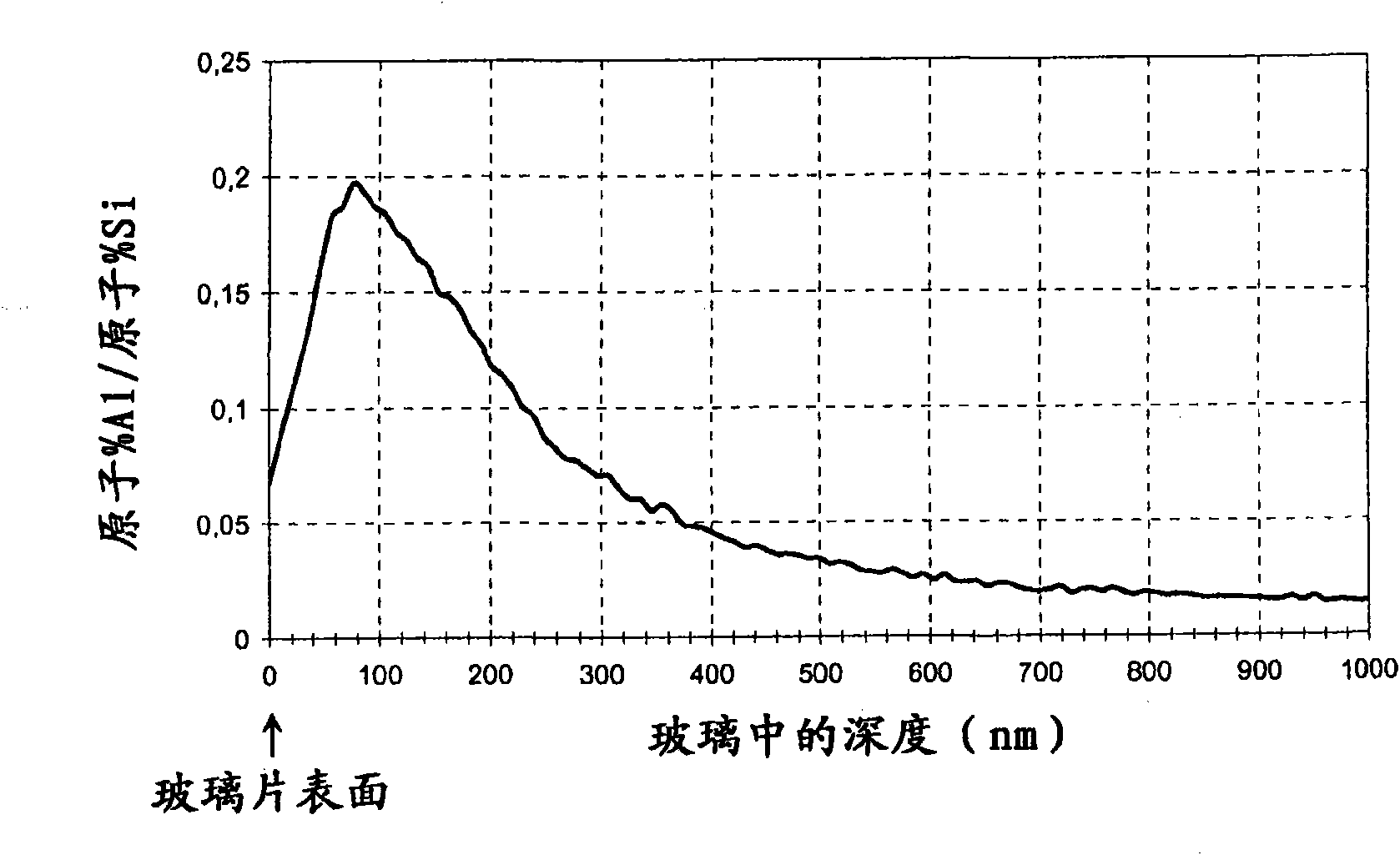

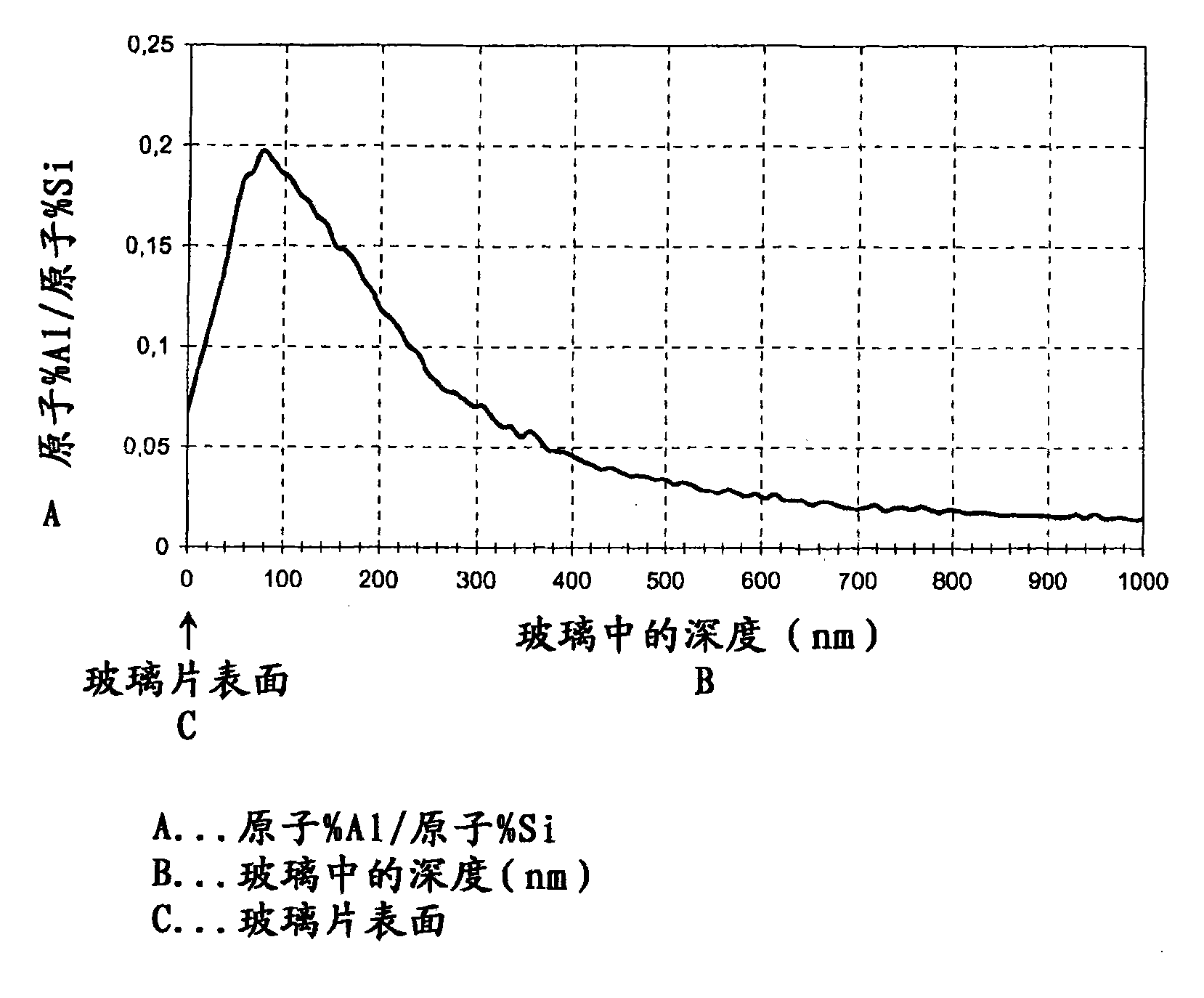

[0060] The glass slides treated above were analyzed by the same technique as described in Example 1. Analysis showed that Al2O3 nanoparticles had bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com