Method for rapidly measuring physical and chemical quality indexes of in-use lubricating oil

A quality index, lubricating oil technology, used in measuring devices, color/spectral property measurement, material analysis by optical means, etc., to save manpower and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

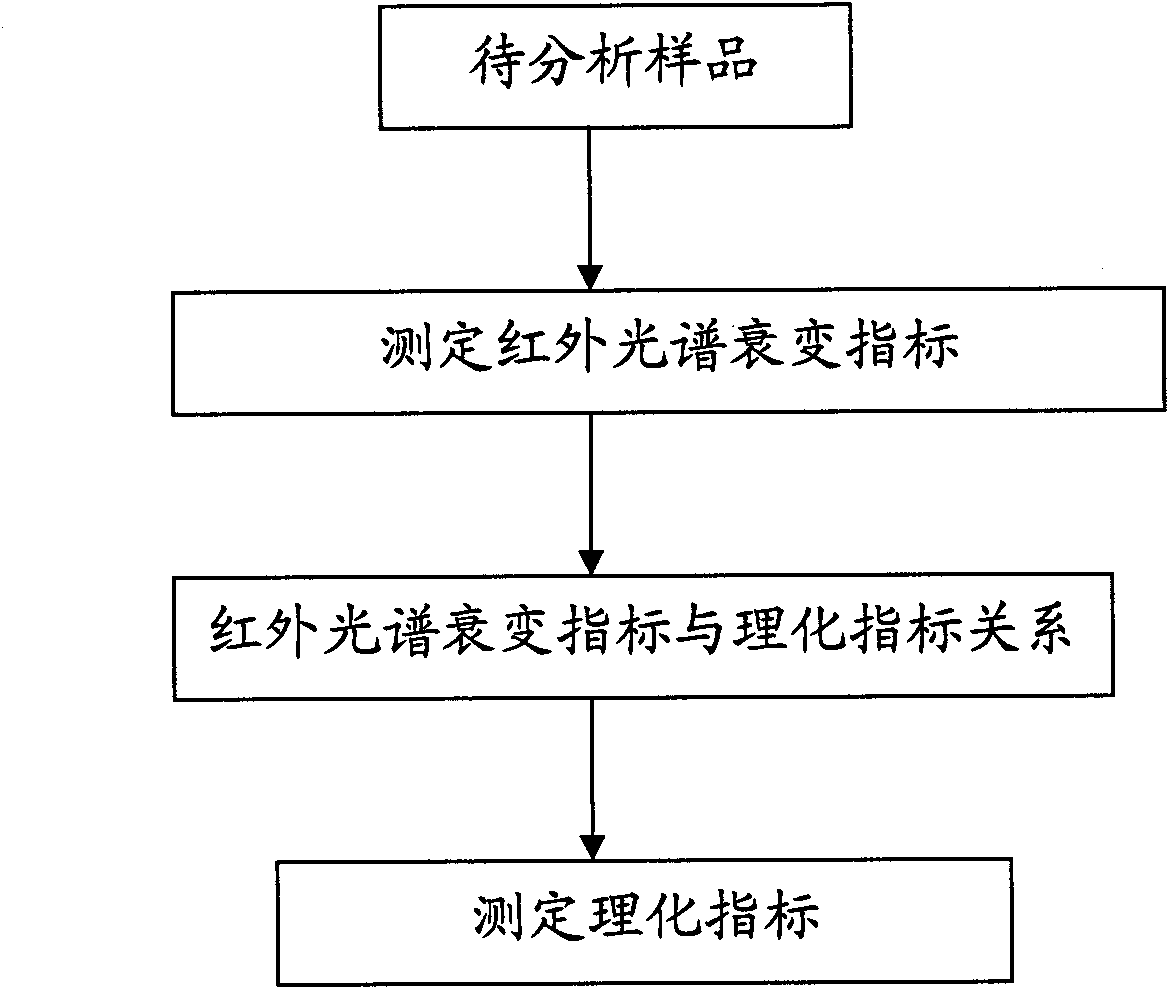

Method used

Image

Examples

example 1

[0043] Example 1: Determination of the oil quality index of GL-5 80W / 90 gear oil in use

[0044] 1) The collection of lubricating oil in the oil sample training set

[0045] Collect 53 oil samples of GL-5 80W / 90 gear oil in use.

[0046] 2) Determination of the infrared spectrum decay index and physical and chemical quality index of lubricating oil, the measurement results are shown in Table 1 (due to the huge data, only the maximum value, minimum value and average value are listed in the table).

[0047]According to ASTM E 2412 method, determine the infrared spectrum decay index of oil in use. The instrument is a Tensor 27 infrared spectrometer with a spectral range of 550-4100cm -1 ; Transmission sample cell, the optical path is 0.1mm.

[0048] The physical and chemical quality indicators were determined according to standard methods.

[0049] Table 1

[0050]

[0051]

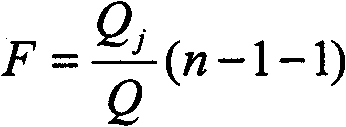

[0052] 3) Establish the relationship between physical and chemical quality indicators and infr...

example 2

[0062] Example 2: Determination of GL-5 85W / 90 gear oil in-use oil quality index

[0063] 1) Collect samples of lubricating oil in use

[0064] Collect GL-5 85W / 90 gear oil in-use oil samples, 25 pieces.

[0065] 2) Determination of the infrared spectrum decay index and physical and chemical quality index of lubricating oil, the measurement results are shown in Table 4 (due to the huge data, only the maximum value, minimum value and average value are listed in the table).

[0066] According to ASTM E 2412 method, determine the infrared spectrum decay index of oil in use. The instrument is a Tensor 27 infrared spectrometer with a spectral range of 550-4100cm -1 ; Transmission sample cell, the optical path is 0.1mm.

[0067] The physical and chemical quality indicators were determined according to standard methods.

[0068] Table 4

[0069]

[0070] 3) Establish the relationship between physical and chemical quality indicators and infrared spectral decay indicators

[0...

example 3

[0078] Example 3: Determination of in-use oil quality index of CD 10W / 40 engine oil

[0079] 1) Collect samples of lubricating oil in use

[0080] Collect CD 10W / 40 engine oil in-use oil samples, 52 pieces.

[0081] 2) Determination of the infrared spectrum decay index and physical and chemical quality index of lubricating oil, the measurement results are shown in Table 7 (due to the huge data, only the maximum value, minimum value and average value are listed in the table).

[0082] According to ASTM E 2412 method, determine the infrared spectrum decay index of oil in use. The instrument is a Tensor 27 infrared spectrometer with a spectral range of 550-4100cm -1 ; Transmission sample cell, the optical path is 0.1mm.

[0083] The physical and chemical quality indicators were determined according to standard methods.

[0084] Table 7

[0085]

[0086] 3) Establish the relationship between physical and chemical quality indicators and infrared spectral decay indicators

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com