Water treatment agent and preparation method and application thereof

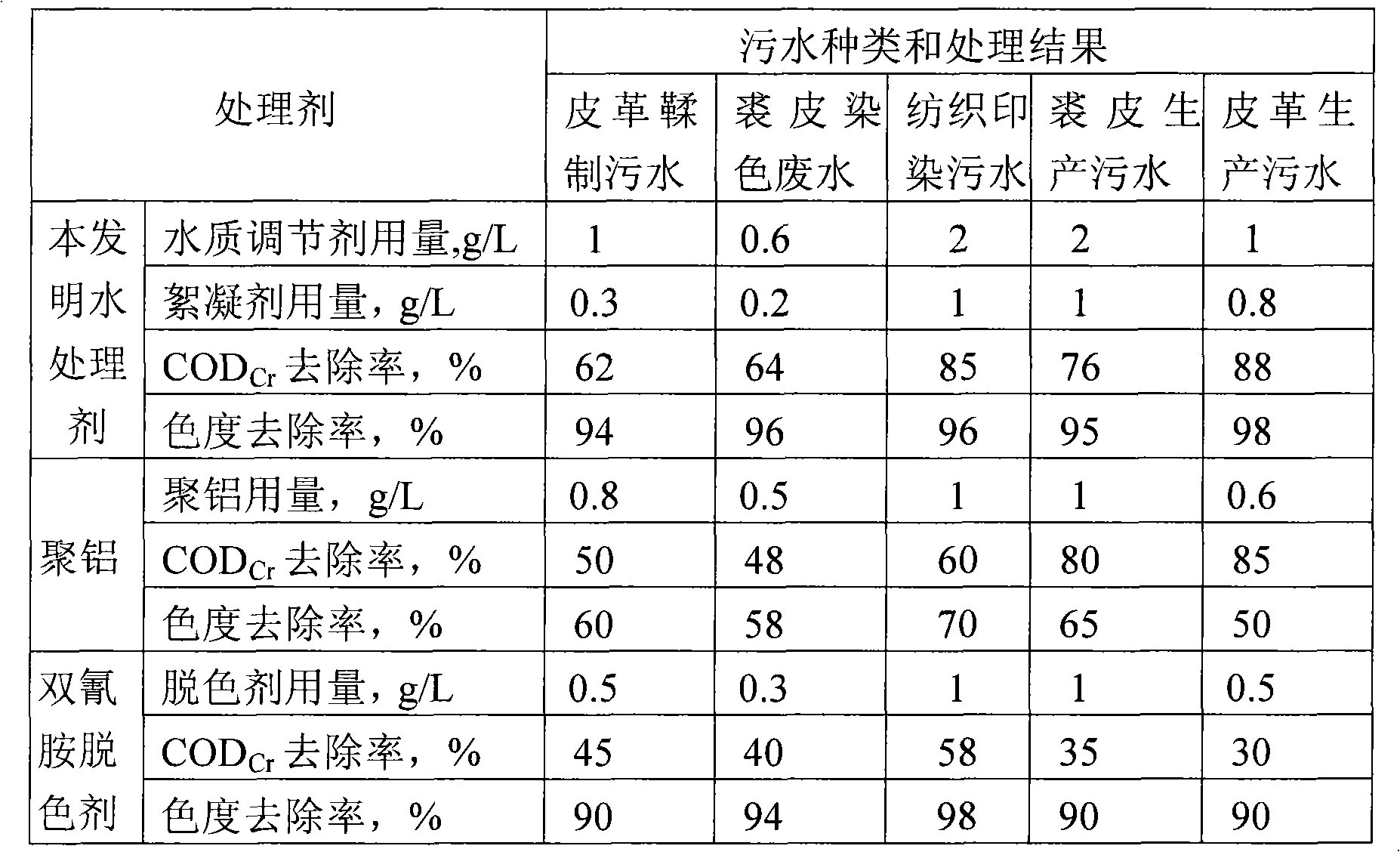

A technology of water treatment agent and water quality conditioner, which is applied in textile industry wastewater treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of secondary environmental pollution, limited decolorization effect, and high treatment cost. , to achieve the effect of no secondary pollution, enhanced floc settling performance, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of water quality conditioner: put 80kg of calcium oxide and 10kg of aluminum potassium sulfate into a pulverizer, adjust the sieve aperture of the pulverizer to 100 mesh, and pulverize twice; then mix 10kg of magnesium sulfate heptahydrate with the above pulverized powder The mixture is poured into a mixing tank, and mixed for 24 hours to obtain a water quality regulator;

[0026] 2. Preparation of flocculant: put 30kg of ferrous sulfate and 90kg of magnesium sulfate heptahydrate into a pulverizer, adjust the sieve aperture of the pulverizer to 150 mesh, and pulverize once; then mix 1kg of polyacrylamide (molecular weight 11 million) with pulverizer The good powder is poured into the mixing tank and mixed for 20 hours to obtain the iron-magnesium composite decolorizing flocculant;

[0027] Store the water quality conditioner and flocculant prepared above separately.

[0028] 3. Wastewater treatment: apply the above water treatment agent to leather tannin...

Embodiment 2

[0033] 1. Preparation of water quality conditioner: put 75kg of calcium oxide and 10kg of aluminum potassium sulfate into a pulverizer, adjust the sieve aperture of the pulverizer to 120 mesh, and pulverize twice; then mix 20kg of magnesium sulfate heptahydrate with the above pulverized powder The mixture is poured into a mixing tank, and mixed for 40 hours to obtain a water quality regulator;

[0034] 2. Preparation of flocculant: put 30kg of ferrous sulfate and 70kg of magnesium sulfate heptahydrate into a pulverizer, adjust the sieve aperture of the pulverizer to 150 mesh, and pulverize once; then mix 3kg of polyacrylamide (molecular weight: 11 million) with the above Pour the pulverized powder into a mixing tank and mix for 5 hours to obtain the iron-magnesium composite decolorizing flocculant;

[0035] Store the water quality conditioner and flocculant prepared above separately.

[0036] 3. Wastewater treatment: apply this water treatment agent to fur dyeing wastewater t...

Embodiment 3

[0041] 1. Preparation of water quality conditioner: put 60kg of calcium oxide and 20kg of aluminum potassium sulfate into a pulverizer, adjust the sieve aperture of the pulverizer to 100 mesh, and pulverize twice; then mix 15kg of magnesium sulfate heptahydrate with the pulverized above-mentioned powder The mixture is poured into a mixing tank, and mixed for 35 hours to obtain a water quality regulator;

[0042]2. Preparation of flocculant: Put 10kg of ferrous sulfate and 90kg of magnesium sulfate heptahydrate into a pulverizer, adjust the sieve aperture of the pulverizer to 120 mesh, and pulverize once; then mix 5kg of polyacrylamide (molecular weight: 11 million) with the above The pulverized powder is poured into a mixing tank and mixed for 10 hours to obtain an iron-magnesium composite decolorizing flocculant;

[0043] Store the water quality conditioner and flocculant prepared above separately.

[0044] 3. Wastewater treatment: apply this water treatment agent to textile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com