Airtight oil dispatching system of oil depot

A technology for oil and petroleum, applied in the direction of special distribution devices, etc., can solve the problems of unsafe operation and poor reliability, and achieve the effects of improving operation safety, improving reliability and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

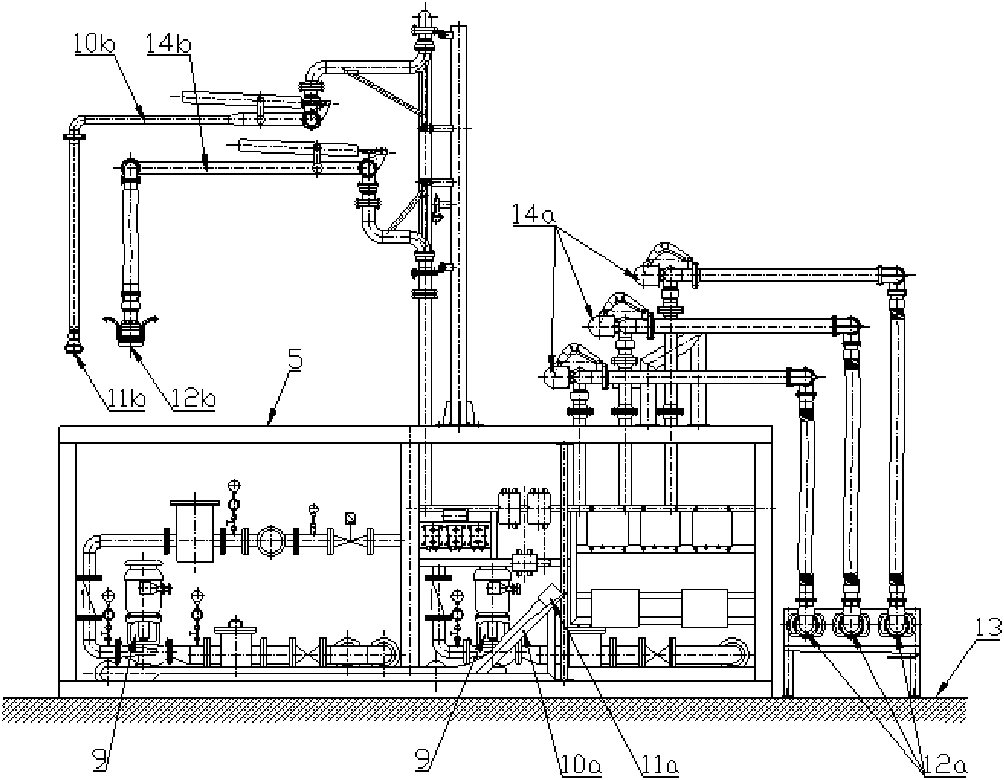

[0026] The present invention will be further described below through a preferred embodiment in conjunction with the accompanying drawings.

[0027] The oil depot airtight delivery system of the present invention comprises a closed oil tank car 16 and an oil delivery platform 17, wherein:

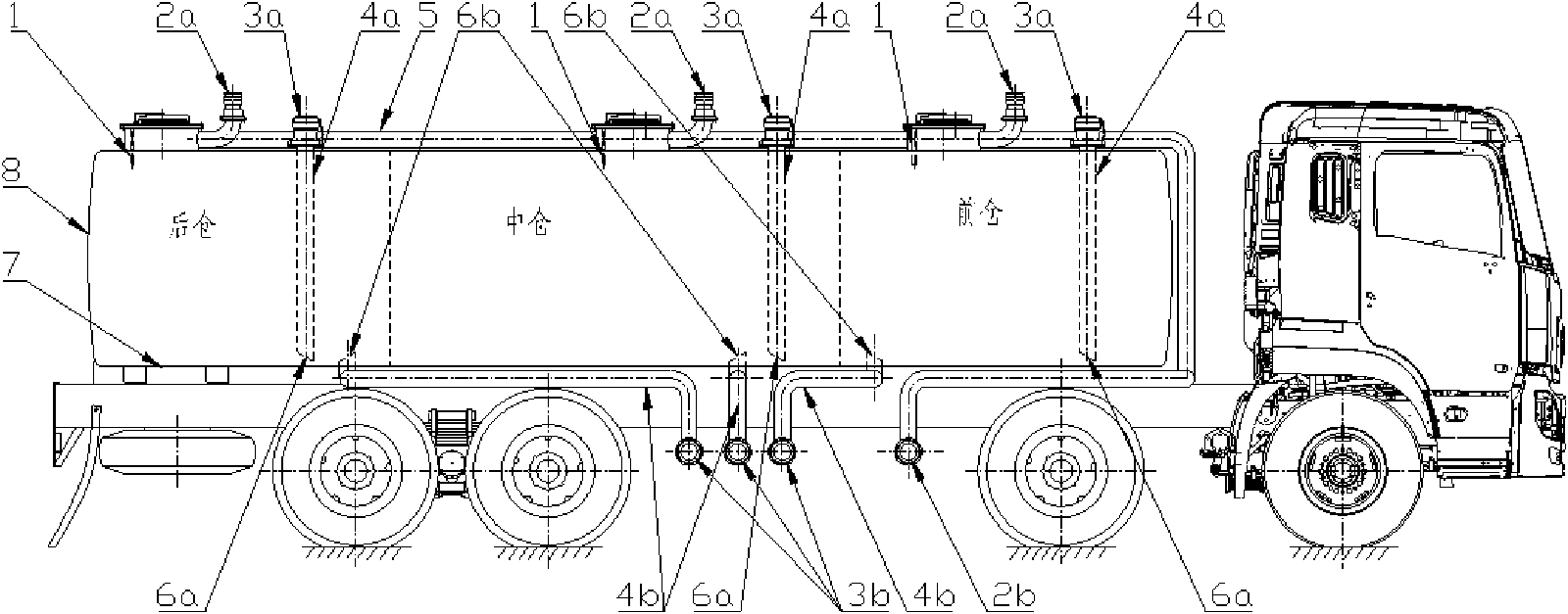

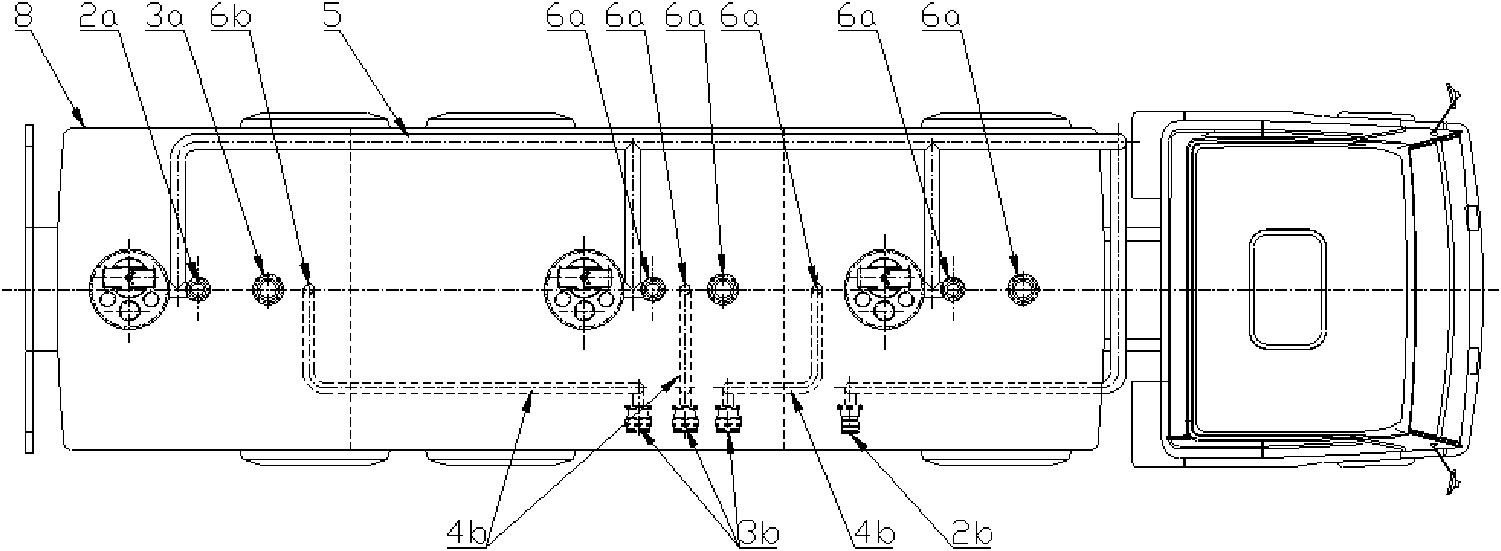

[0028] Airtight tank truck 16 as figure 1 , 2 As shown, the second oil delivery interface and the second oil vapor recovery interface are installed on the oil tank truck 16. Specifically: the second oil delivery interface includes the top second oil delivery interface 3a on the top of the oil tank 8 and the second oil delivery interface on the side of the oil tank 8. The second oil delivery interface 3b on the side of the lower part, the second oil delivery interface 3a on the top extends into the oil tank 8 of the tank truck 16 through the top oil delivery pipeline 4a, and the inner port 6a of the top oil delivery pipeline 4a extends to the oil tank 8 In the bottom, the second oil deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com